In the field of modern advertising signs and commercial displays, PVC Backlit Flex Banner is widely used in light boxes, exhibition booths, shopping mall guide systems, outdoor billboards and other scenes because of its light weight, flexibility, easy installation and good light transmittance. However, in practical applications, how to ensure high brightness and color reproduction of the picture while taking into account the material's UV resistance, weather resistance and structural stability has become a key issue in design and production.

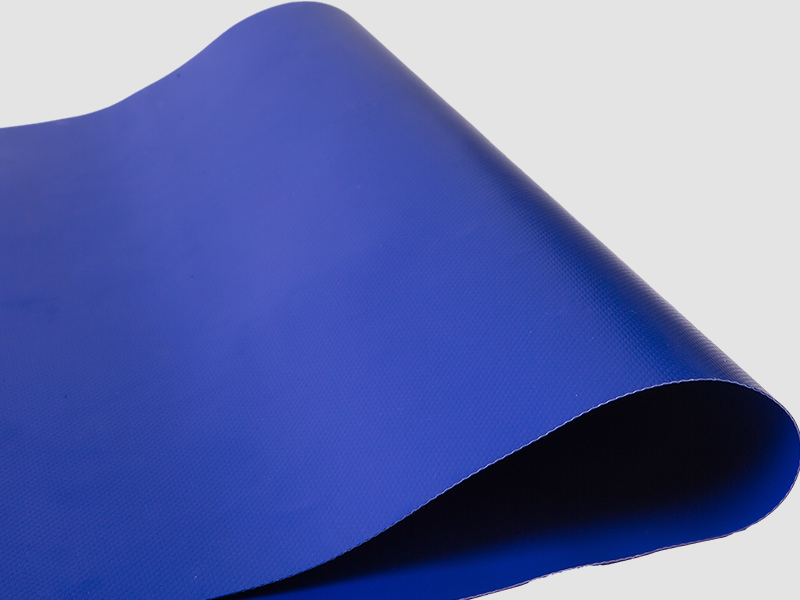

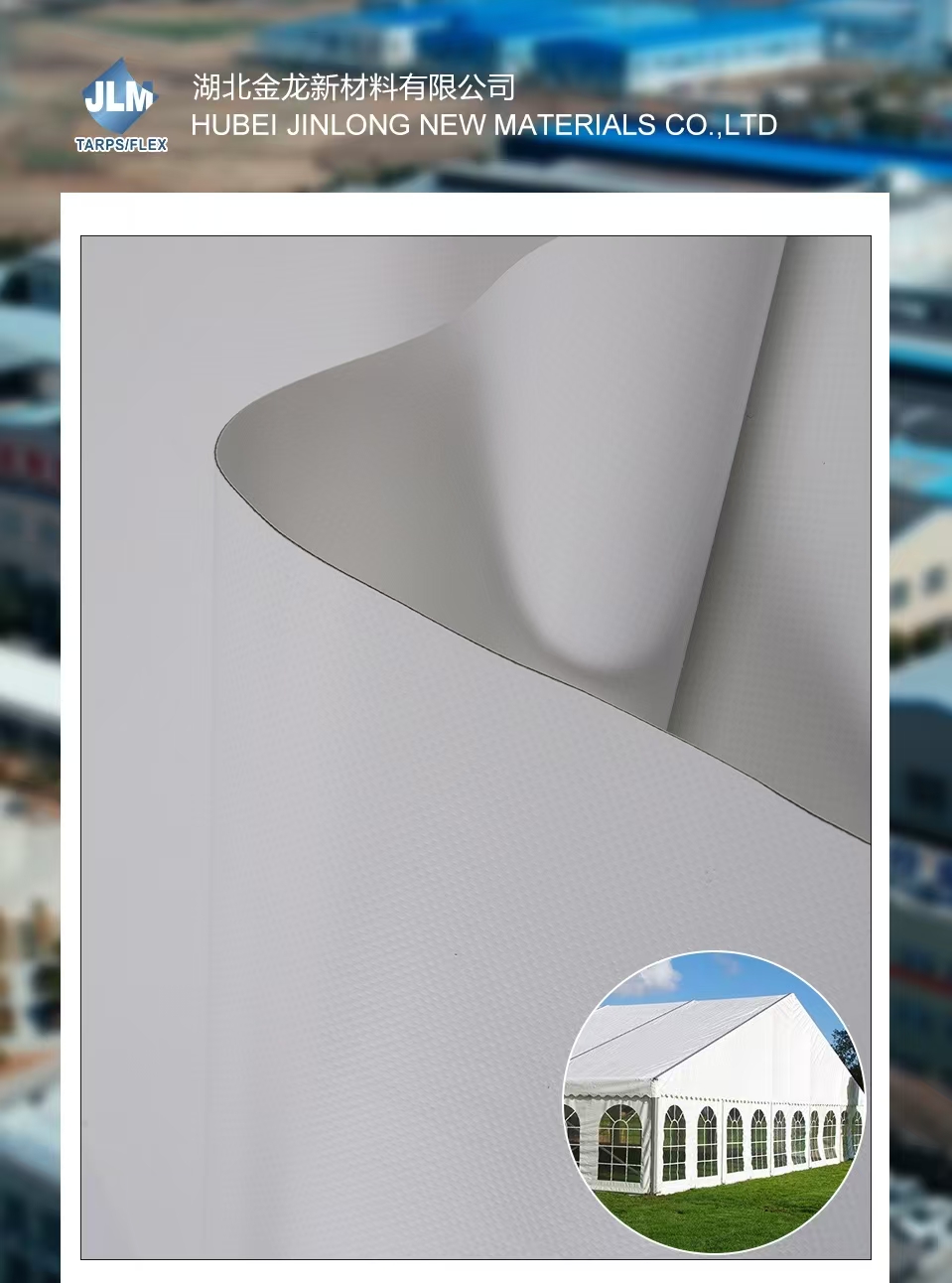

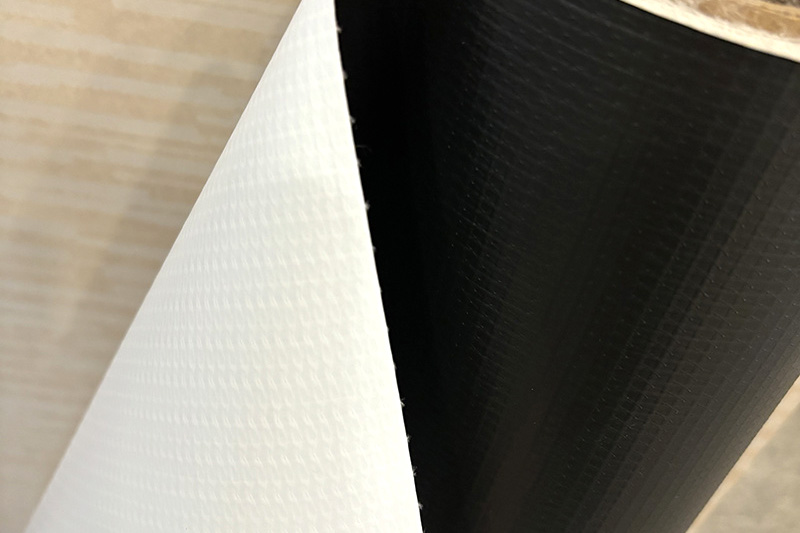

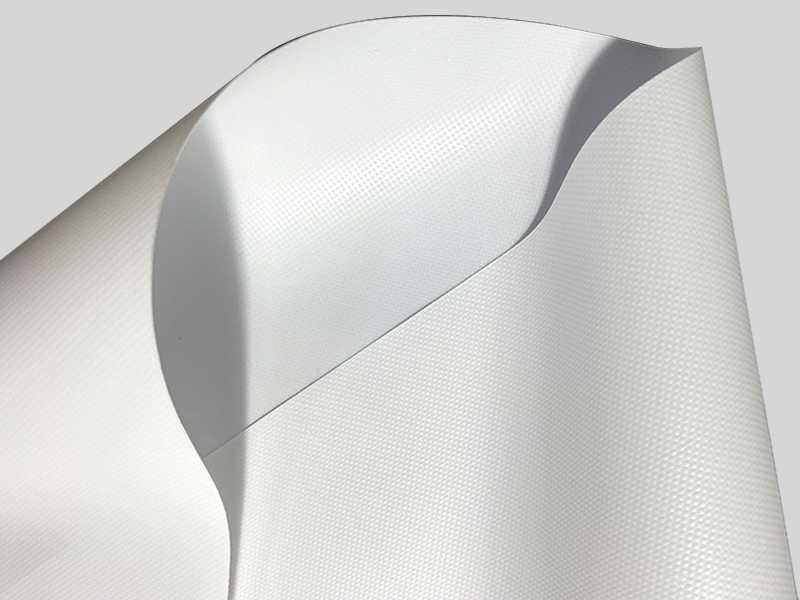

In terms of material selection, high-quality PVC backlit flex banners should have good light transmittance and shading properties. Usually a double-layer composite process is used, with the middle layer being a high-strength mesh cloth to enhance tensile strength, and the outer layer being a specially treated PVC coating, so that it can evenly diffuse light and is not easy to deform or see through the bottom. At the same time, PVC raw materials with anti-UV stabilizers added should be selected to reduce problems such as color fading, brittleness and even cracking caused by long-term exposure to sunlight.

In terms of printing technology, in order to achieve high-brightness display effects, it is recommended to use high-precision digital inkjet technology and a dedicated backlight printing mode. By optimizing the ink penetration depth and dot distribution, the picture clarity and color saturation can be effectively improved. In addition, proper control of ink volume and drying temperature can help prevent ink accumulation from affecting the uniformity of light transmission and avoid the phenomenon of "black spots" or "dark shadows".

In the matching of the lighting system, the choice of light source directly affects the final visual effect. The current mainstream solutions include LED light strips, cold cathode fluorescent lamps (CCFL), etc., among which LED is more popular because of its energy saving, long life, rich colors and low heat generation. During installation, the lamp distance and the angle of the reflector should be reasonably arranged to ensure that the light is evenly irradiated to the entire surface of the advertising cloth to avoid local overbrightness or shadow interference.

In terms of adaptability to outdoor environments, PVC backlit soft curtain advertising cloth must have certain waterproof, windproof and dustproof capabilities. It is recommended to set windproof buckles or reinforced edge bands in the installation structure to prevent strong winds from tearing the cloth surface; at the same time, hot-melt edging or metal eyelets are used at the edges for reinforcement to improve the overall tensile strength. For projects that are used outdoors for a long time, surface dust and pollutants should also be cleaned regularly to prevent stains from penetrating and affecting the light transmission effect.

In terms of service life and environmental protection, although PVC materials have strong durability, their recycling is relatively complicated. Therefore, while pursuing high performance, we can also pay attention to new environmentally friendly backlight fabrics, such as PET material substitutes, which have more sustainable advantages while maintaining good optical properties.

To achieve a balance between high-brightness display and outdoor durability of PVC backlight soft curtain advertising cloth, it is necessary to coordinate and optimize multiple aspects such as material formulation, printing process, light source configuration, structural design and post-maintenance. Only by combining scientific material selection, fine processing and reasonable installation can we truly meet the dual needs of commercial display for visual impact and long-term stability.

English

English русский

русский Français

Français Español

Español