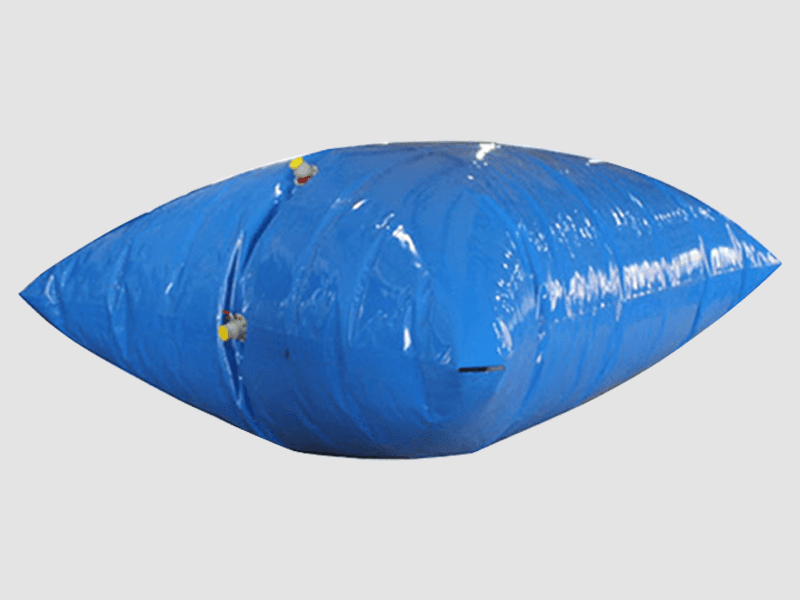

Are PVC pillow water tanks safe for storing drinking water?

PVC pillow water tanks can be safe for storing drinking water when they are manufactured and maintained according to appropriate standards and guidelines. Here are some factors to consider regarding the safety of PVC pillow water tanks for drinking water storage:

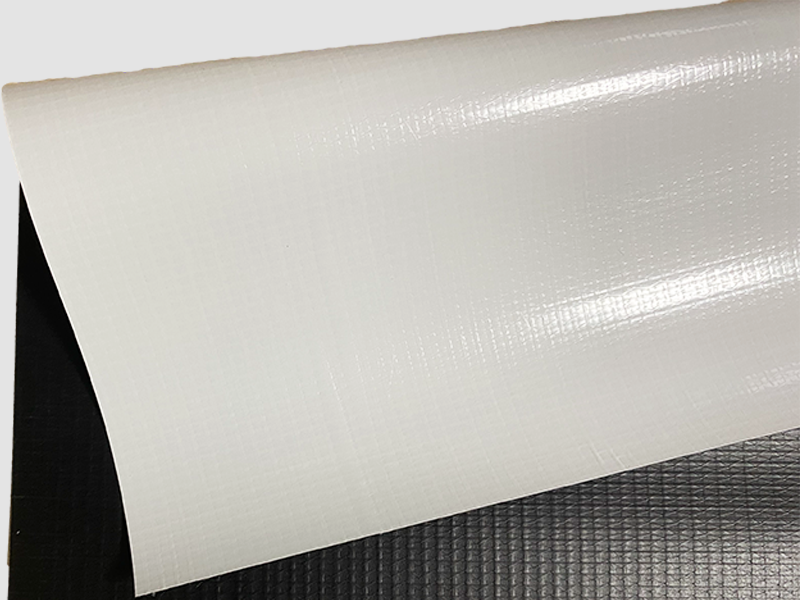

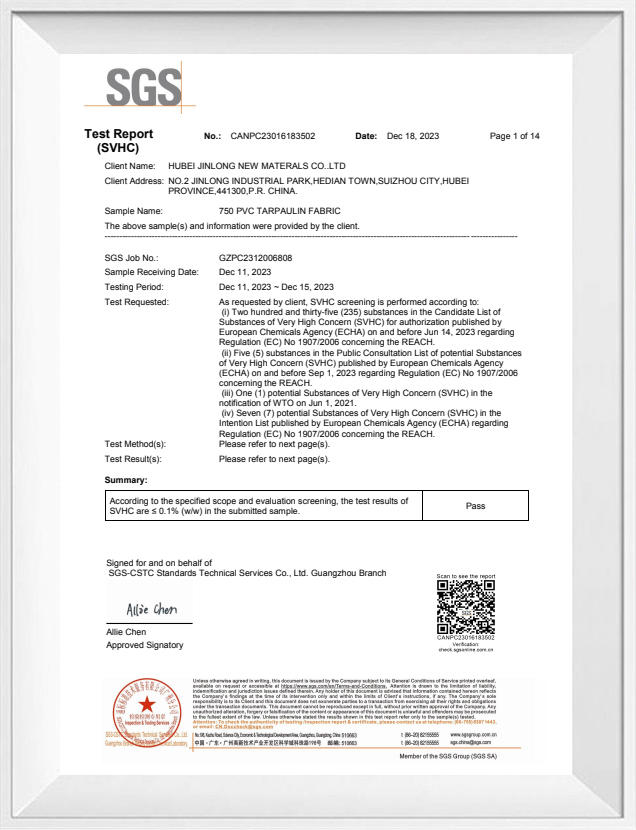

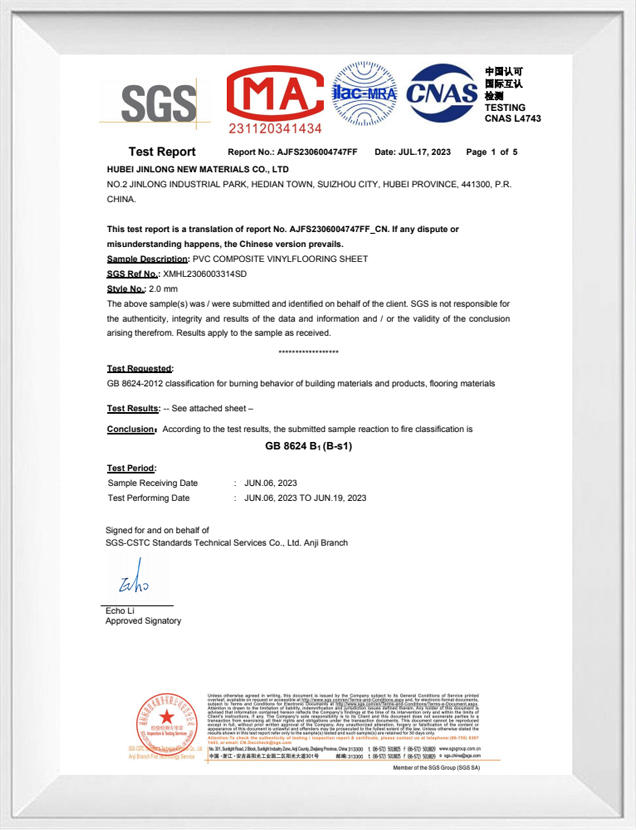

Material Quality: Ensure that the PVC material used in the construction of the tank is of high quality and complies with relevant safety standards for contact with potable water. Look for tanks made from food-grade PVC materials that are free from harmful chemicals or additives.

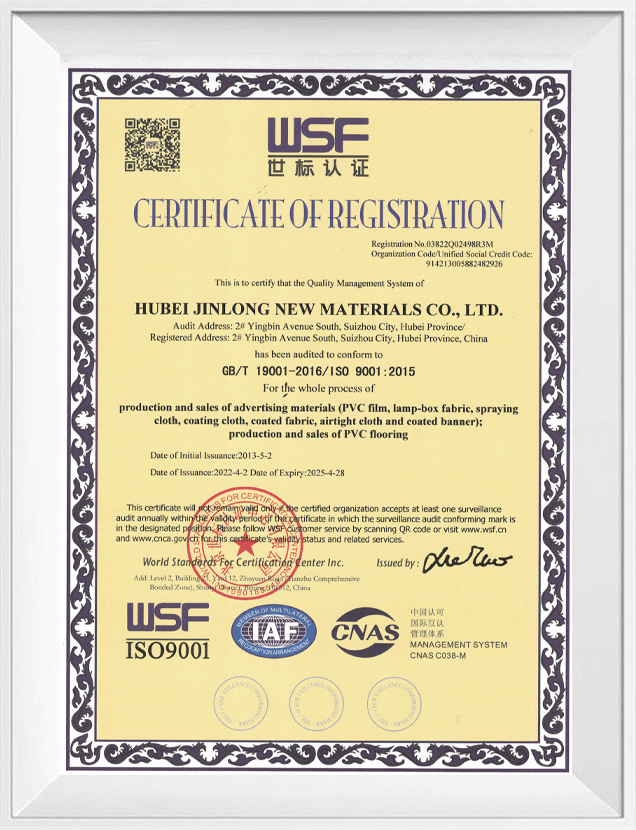

Certifications: Look for certifications or approvals from regulatory agencies or independent organizations that validate the suitability of the PVC pillow water tank for storing drinking water. Certifications such as NSF/ANSI 61 or FDA approval indicate compliance with health and safety standards.

Installation Practices: Ensure that the tank is placed on a stable and level surface, away from sources of potential contamination such as chemicals, sewage, or animal waste.

Cleaning and Maintenance: Regularly clean and disinfect the PVC pillow water tank to prevent the growth of algae, bacteria, or other contaminants. Use approved cleaning agents and follow recommended maintenance schedules to ensure water quality and safety.

Monitoring and Testing: Periodically monitor the quality of the water stored in the PVC pillow tank to ensure it meets drinking water standards. Conduct tests for parameters such as pH, turbidity, chlorine residual, and microbial contamination as needed.

By adhering to these considerations and taking appropriate precautions, PVC pillow water tanks can provide a safe and reliable solution for storing drinking water in various applications, including emergency preparedness, remote locations, and temporary water supply needs.

What measures does PVC Pillow Water Tank take to ensure water quality and prevent pollution?

PVC pillow water tanks implement several measures to ensure water quality and prevent pollution, safeguarding the stored water from contamination. Here are some common measures:

Material Selection: PVC pillow water tanks are typically made from food-grade PVC materials that are specifically designed for contact with potable water. These materials are chosen for their inert nature and resistance to leaching harmful substances into the water.

Seam Welding: PVC pillow water tanks are constructed using advanced seam welding techniques to ensure watertight seals. High-frequency or heat sealing methods are commonly employed to bond the PVC fabric together securely, minimizing the risk of leaks or seepage.

Anti-Algae Treatments: Some PVC pillow water tanks are treated with anti-algae coatings or additives to prevent the growth of algae and biofilm inside the tank. These treatments help maintain water clarity and quality by inhibiting the proliferation of microorganisms.

UV Protection: UV-resistant coatings or layers may be applied to the outer surface of PVC pillow water tanks to protect them from sunlight exposure. This not only extends the lifespan of the tank but also prevents degradation of the PVC material, reducing the risk of contamination from deteriorating tank surfaces.

Regular Inspection and Maintenance: Users are advised to conduct regular inspections of PVC pillow water tanks to check for signs of damage, wear, or degradation. Any issues should be promptly addressed to prevent potential contamination. Routine maintenance tasks, such as cleaning and disinfection, are also essential for preserving water quality.

Proper Installation: PVC pillow water tanks should be installed on stable, level ground away from sources of potential contamination, such as chemicals, sewage, or animal waste. Adequate measures should be taken to secure the tank and prevent it from shifting or tipping over.

English

English русский

русский Français

Français Español

Español