What weight capacities and pressure ratings can drop stitch fabric support?

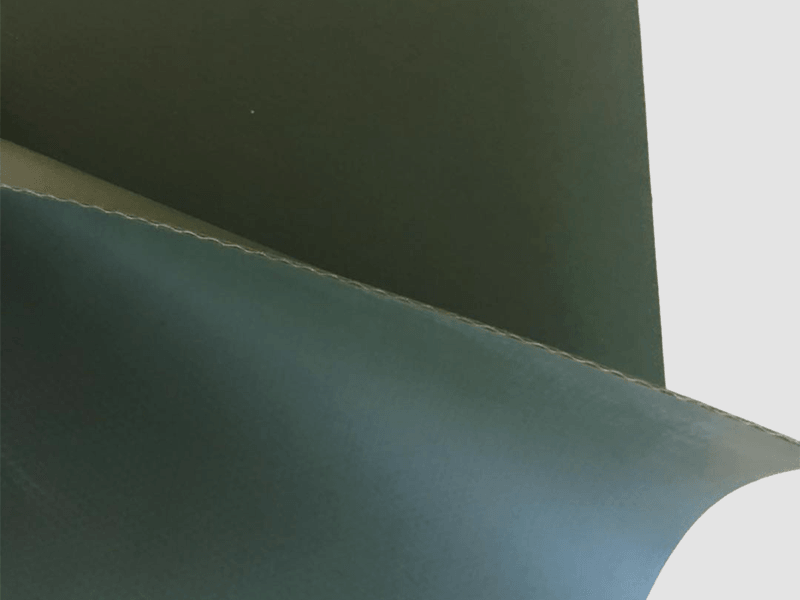

The weight capacities and pressure ratings of

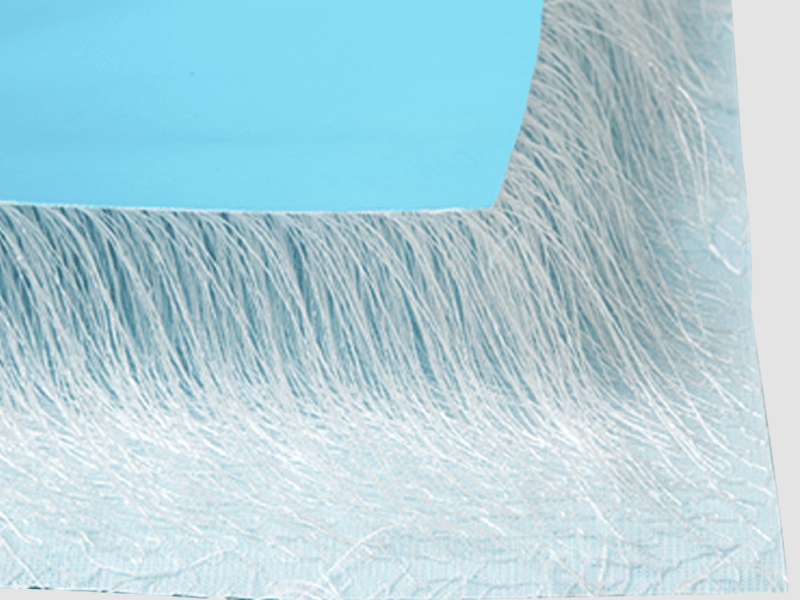

drop stitch fabric can vary depending on several factors, including the specific design, construction, and intended use of the fabric. However, drop stitch fabric is known for its high strength and durability, allowing it to support significant weight and withstand elevated pressure levels. Here are some general considerations regarding weight capacities and pressure ratings for drop stitch fabric:

Weight Capacities:Drop stitch fabric is capable of supporting various loads, ranging from lightweight objects to heavier items such as furniture, equipment, or even people.

Weight capacities may be specified by the manufacturer based on factors such as the size and dimensions of the fabric, the thickness of the reinforcement threads, and the intended application.

Larger and thicker drop stitch fabrics typically have higher weight capacities due to their increased structural integrity and load-bearing capabilities.

Pressure Ratings:Drop stitch fabric is designed to withstand internal air pressure when inflated, allowing it to maintain its shape and structure under load.

The pressure rating of drop stitch fabric is typically expressed in pounds per square inch (psi) or bar and represents the maximum air pressure that the fabric can withstand without rupturing or failing.

Standard pressure ratings for drop stitch fabric can range from around 10 psi to 20 psi or higher, depending on factors such as the fabric's construction, materials, and intended application.

Higher pressure ratings are typically associated with inflatable products that require greater rigidity and stability, such as paddleboards, kayaks, or inflatable boats.

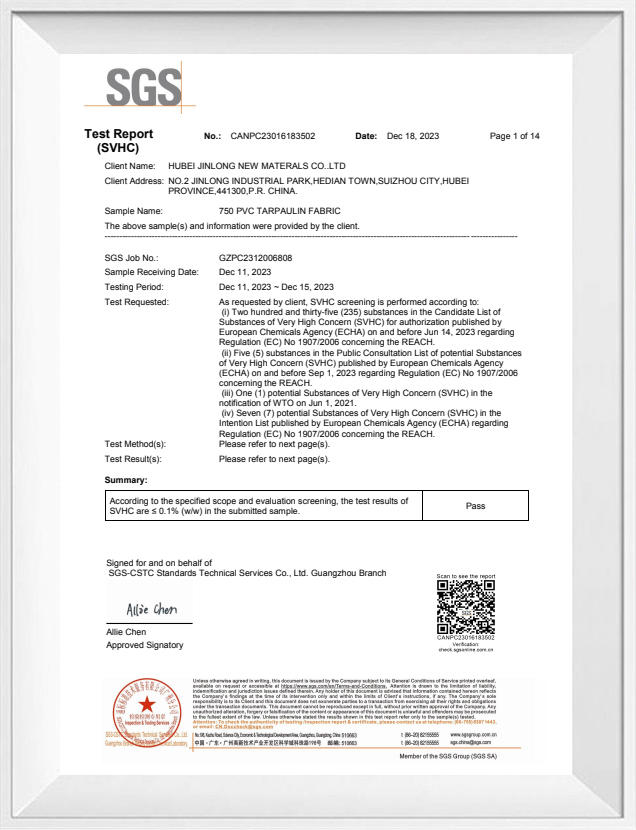

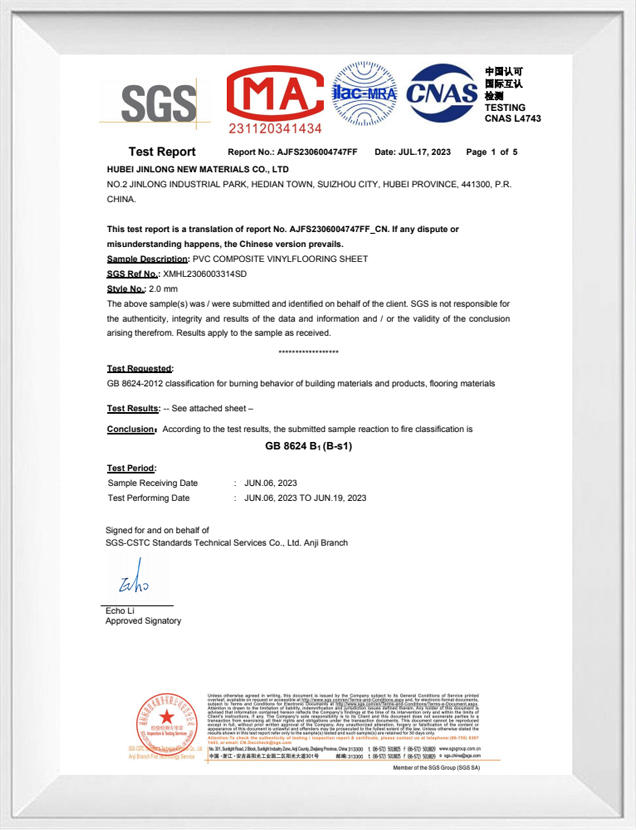

Testing and Certification:Drop stitch fabric products may undergo testing and certification to verify their weight capacities and pressure ratings in accordance with industry standards and regulations.

Testing methods may include inflation testing, pressure testing, and load testing to assess the fabric's performance under different conditions.

English

English русский

русский Français

Français Español

Español