What printing techniques are compatible with PVC frontlit flex banners?

PVC frontlit flex banners are versatile materials that can be printed using various techniques, depending on factors such as the equipment available, desired print quality, and budget. Some of the common printing techniques compatible with PVC frontlit flex banners include:

Digital Printing: Digital printing is one of the most common and versatile methods for printing on PVC frontlit flex banners. It involves directly transferring digital files onto the banner material using inkjet printers or large format printers. Digital printing offers high-quality results, vibrant colors, and the ability to reproduce complex designs accurately.

Solvent Printing: Solvent printing utilizes solvent-based inks that chemically bond with the surface of the PVC material. This method is suitable for outdoor applications as the solvent inks provide excellent durability and weather resistance. Solvent printing is often used for large-scale projects such as billboards, banners, and outdoor signage.

UV Printing: UV printing involves curing UV inks with ultraviolet light, resulting in instant drying and adhesion to the PVC frontlit flex banner. UV printing offers high-quality prints with sharp details and vibrant colors. It is environmentally friendly as it produces minimal volatile organic compounds (VOCs) and is suitable for both indoor and outdoor applications.

Latex Printing: Latex printing utilizes water-based latex inks that bond with the PVC material upon curing. This method offers vibrant colors, excellent image quality, and durability. Latex printing is eco-friendly, as it produces low levels of VOCs, making it suitable for indoor applications where ventilation may be limited.

Dye Sublimation Printing: Dye sublimation printing involves transferring dye onto a special transfer paper, which is then heat-pressed onto the PVC frontlit flex banner. This method is ideal for printing complex designs, photographs, and images with gradients. Dye sublimation printing results in vibrant colors and excellent color accuracy, making it suitable for indoor applications such as trade show displays and banners.

Screen Printing: While less common for PVC frontlit flex banners due to the rise of digital printing technologies, screen printing can still be used for large-scale projects or when specific color matching is required. Screen printing involves pushing ink through a mesh stencil onto the banner material. It offers durability and is suitable for both indoor and outdoor applications.

How do different compositions affect durability and print quality?

The composition of

PVC frontlit flex banners can significantly affect both durability and print quality. Here's how different compositions may impact these factors:

Material Thickness: Thicker PVC frontlit flex banners tend to be more durable and resistant to tearing or puncturing, especially in outdoor environments where they may be exposed to harsh weather conditions or high winds. Thicker materials also provide better opacity, reducing the visibility of any underlying structures or lighting.

Weight: Heavier PVC frontlit flex banners typically offer greater durability and stability, especially when installed in outdoor settings where they may be subject to wind stress or other environmental factors. However, lighter-weight materials can be more cost-effective and easier to handle during installation.

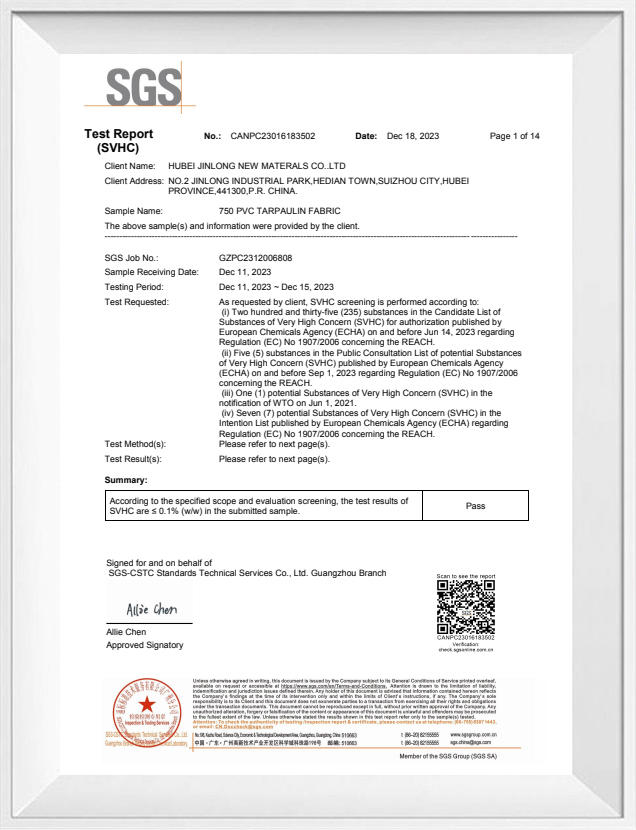

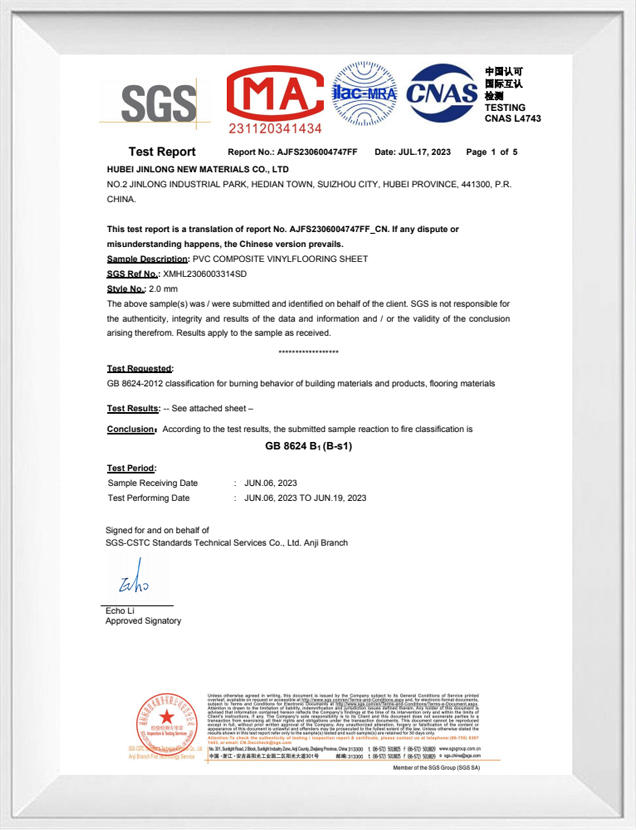

Coating or Lamination: Some PVC frontlit flex banners may feature coatings or laminations designed to enhance durability and print quality. For example, a UV-resistant coating can help protect the printed graphics from fading or discoloration due to prolonged sun exposure. Laminations can also add an extra layer of protection against abrasion, moisture, and other forms of wear and tear.

Surface Texture: The texture of the PVC material can impact print quality, particularly with regards to sharpness and detail. Smooth surfaces typically produce more accurate and vibrant prints, especially for intricate designs or fine text. However, textured surfaces may offer advantages in terms of reducing glare or hiding minor imperfections in the substrate.

Ink Compatibility: The composition of the PVC material can affect its compatibility with different types of printing inks. Some PVC frontlit flex banners may be specifically designed for use with solvent-based, UV-curable, latex, or dye sublimation inks. Using the appropriate ink type for the substrate is crucial for achieving optimal print quality, adhesion, and durability.

Environmental Factors: PVC frontlit flex banners may be exposed to a wide range of environmental conditions, including temperature fluctuations, UV radiation, moisture, and pollution. The composition of the material can influence its resistance to these factors, with high-quality PVC formulations offering better long-term performance and color retention.

English

English русский

русский Français

Français Español

Español