Are there specialized applications where Polyester TPU outperforms other materials?

Polyester TPU (thermoplastic polyurethane) can offer specific advantages in certain applications, outperforming other materials in various ways. Here are some specialized applications where Polyester TPU may excel:

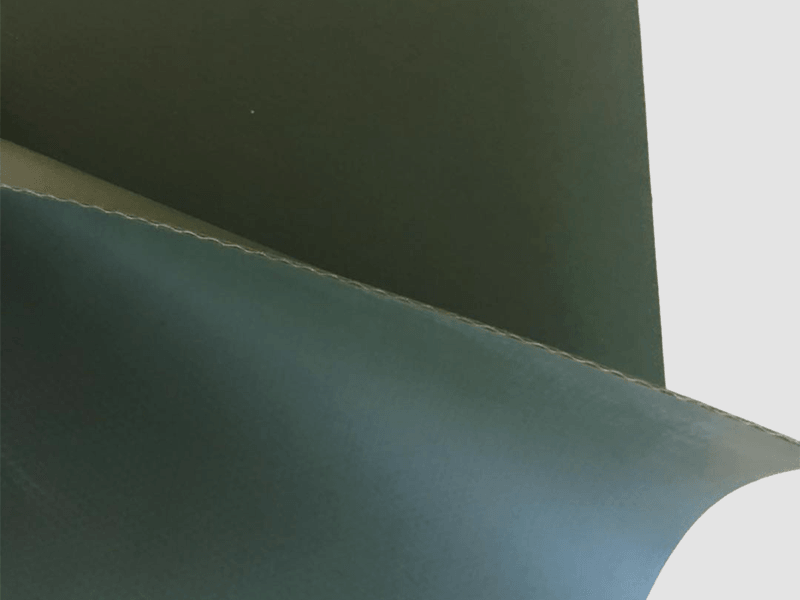

Outdoor Gear and Apparel:Polyester TPU is well-suited for outdoor gear and apparel applications due to its excellent weather resistance, durability, and abrasion resistance.

It is commonly used in the production of waterproof and breathable outerwear, footwear, backpacks, tents, and camping equipment.

Polyester TPU coatings or laminates can provide superior protection against moisture, wind, and UV radiation compared to traditional textiles, ensuring comfort and performance in outdoor environments.

Technical Textiles and Protective Gear:Polyester TPU is utilized in technical textiles and protective gear where high performance and reliability are paramount.

It is employed in applications such as ballistic vests, protective clothing, industrial gloves, and inflatable structures due to its tear resistance, puncture resistance, and impact absorption properties.

Polyester TPU can provide enhanced safety and protection for workers, athletes, and personnel operating in hazardous or demanding environments.

Automotive Components and Interior Trim:Polyester TPU is used in automotive applications for its flexibility, durability, and resistance to chemicals and abrasion.

It is employed in interior trim components, such as armrests, dashboards, door panels, and seat covers, to provide comfort, aesthetics, and longevity.

Polyester TPU coatings or films can also be applied to automotive fabrics and textiles to improve stain resistance, wear resistance, and ease of cleaning.

Medical Devices and Healthcare Products:Polyester TPU is utilized in medical devices and healthcare products where biocompatibility, flexibility, and resistance to sterilization are required.

It is commonly used in medical tubing, catheters, wound dressings, and prosthetic components due to its biocompatibility, flexibility, and resistance to chemicals and bodily fluids.

Polyester TPU can provide medical professionals and patients with reliable and durable solutions for a wide range of healthcare needs.

Seals, Gaskets, and Industrial Components:Polyester TPU is employed in seals, gaskets, and industrial components where resilience, sealing properties, and resistance to wear and tear are critical.

It is used in applications such as hydraulic seals, O-rings, gaskets, conveyor belts, and vibration dampers to provide effective sealing and protection against environmental factors.

Polyester TPU seals and components can withstand challenging operating conditions in industrial machinery, equipment, and systems, ensuring reliable performance and longevity.

Can Polyester TPU be combined or integrated with other materials in composite structures?

Polyester TPU (thermoplastic polyurethane) can be combined or integrated with other materials in composite structures to create hybrid materials with tailored properties and performance characteristics. Here are some common methods of combining Polyester TPU with other materials:

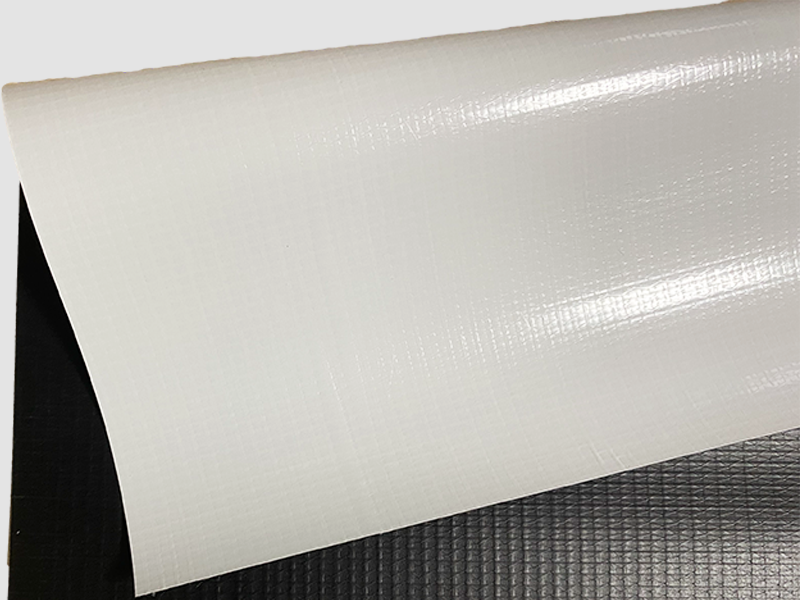

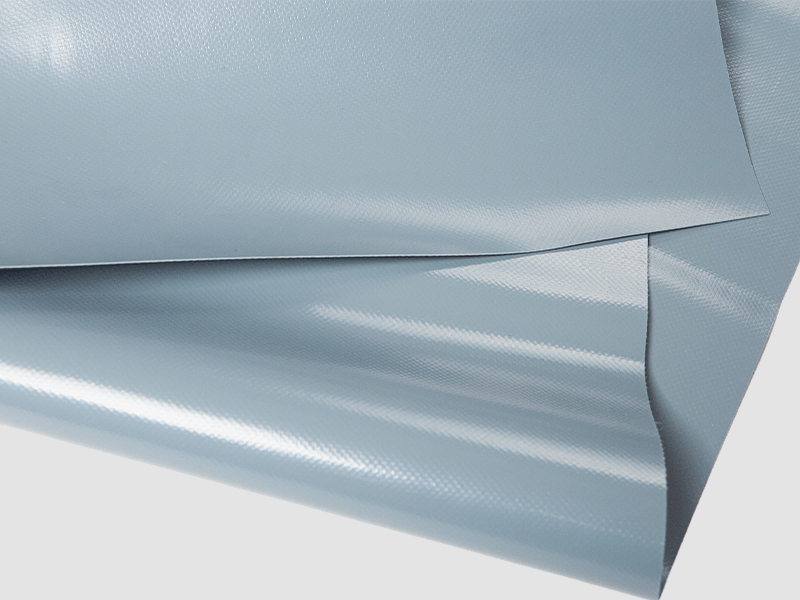

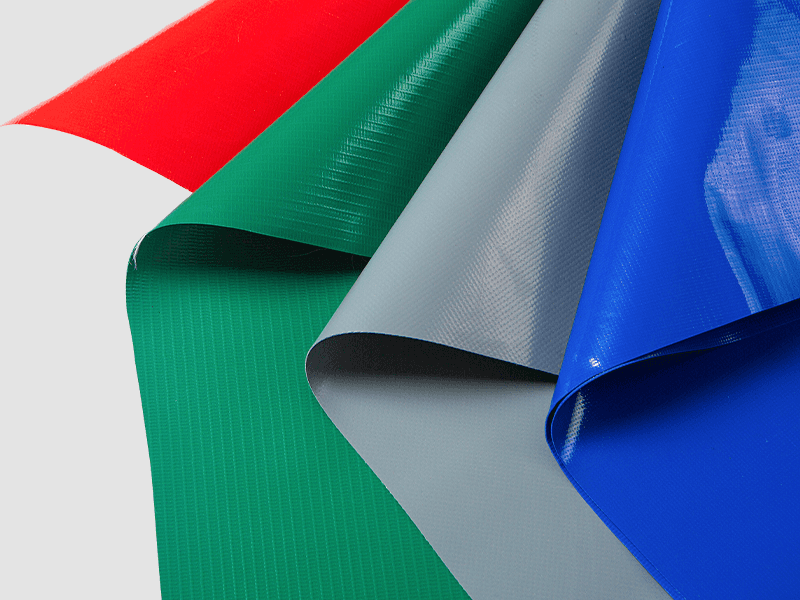

Coatings and Laminates:Polyester TPU can be applied as a coating or laminate onto substrates such as textiles, films, foams, or metal surfaces.

The TPU coating or laminate enhances the substrate's properties, providing benefits such as waterproofing, abrasion resistance, flexibility, and durability.

Common examples include Polyester TPU-coated fabrics for outdoor gear, waterproof membranes for construction, and abrasion-resistant coatings for industrial components.

Adhesive Bonding:Polyester TPU can be used as an adhesive or bonding agent to join different materials together.

TPU adhesives offer strong adhesion to various substrates, including plastics, metals, textiles, and composites, providing excellent bond strength and durability.

Polyester TPU adhesives are used in automotive assembly, footwear manufacturing, electronics assembly, and other industries where reliable bonding is essential.

Overmolding and Insert Molding:Polyester TPU can be overmolded or insert molded onto substrates to create hybrid components with multiple materials.

In overmolding, Polyester TPU is molded over a pre-existing substrate, such as a plastic or metal part, to provide additional features or properties, such as soft-touch grips, seals, or protective coatings.

In insert molding, Polyester TPU is molded around embedded inserts, such as metal inserts or electronic components, to create integrated assemblies with combined functionalities.

Composite Filaments for 3D Printing:Polyester TPU can be combined with other materials, such as thermoplastics or reinforcing fibers, to produce composite filaments for 3D printing (additive manufacturing).

The addition of reinforcing fibers, such as carbon fiber or glass fiber, can enhance the strength, stiffness, and dimensional stability of 3D-printed parts.

Composite filaments with Polyester TPU are used in various industries for rapid prototyping, tooling, and end-use parts production.

Blends and Alloys:Polyester TPU can be blended or alloyed with other thermoplastic materials to create hybrid materials with combined properties.

Blending Polyester TPU with other polymers, such as polyethylene (PE), polypropylene (PP), or polycarbonate (PC), can modify properties such as hardness, stiffness, and melt flow behavior.

These blends are used in applications where a balance of properties is required, such as in automotive interiors, consumer goods, and industrial components.

English

English русский

русский Français

Français Español

Español