1. Introduction to PVC Tarpaulin

1.1. What is PVC Tarpaulin?

PVC Tarpaulin is a strong, flexible, and waterproof material made primarily from polyvinyl chloride (PVC) combined with woven polyester or other reinforcing fabrics. It is widely used for protective covers, tents, banners, truck covers, and many other applications where durability and weather resistance are essential.

1.2. Composition and Manufacturing Process (Polyvinyl Chloride)

PVC Tarpaulin is composed of polyvinyl chloride resin mixed with plasticizers, stabilizers, and other additives to achieve flexibility, strength, and resistance to environmental factors. The manufacturing process involves coating or laminating a polyester fabric base with PVC on one or both sides. This creates a durable composite material that combines the strength of polyester with the protective qualities of PVC. The tarpaulin can be produced in different thicknesses and finishes depending on its intended use.

1.3. Why Choose PVC Tarpaulin Over Other Materials?

Waterproof and Weatherproof: PVC tarpaulin offers excellent protection against rain, snow, and sunlight.

Durability: It withstands harsh conditions including abrasion, tearing, and chemical exposure better than many alternatives.

Flexibility: Despite its toughness, PVC tarpaulin remains flexible and easy to handle and install.

Cost-Effectiveness: Compared to materials like canvas or vinyl, PVC tarpaulin offers a good balance of durability and price.

Versatility: Available in various thicknesses, colors, and finishes, it suits a broad range of industrial, commercial, and residential applications.

2. Key Features and Benefits

2.1. Waterproof and Weather Resistance

PVC Tarpaulin is inherently waterproof, making it an ideal material for outdoor and industrial applications. Whether used as a truck cover, tent, or protective cover for equipment, it effectively prevents water penetration. This waterproof quality ensures that the material performs well even in heavy rain, snow, and humid environments, maintaining its integrity over time.

2.2. UV Resistance and Protection

Another key benefit of PVC Tarpaulin is its UV resistance. The material is designed to withstand prolonged exposure to sunlight without degrading or losing its strength. UV protection prevents fading, cracking, or brittleness, which ensures that PVC tarpaulin products maintain their appearance and durability even after extended outdoor use.

2.3. Tear and Abrasion Resistance

The strong polyester base combined with the PVC coating makes this material highly resistant to tearing and abrasion. It can endure rough handling and exposure to sharp objects, making it suitable for demanding environments like construction sites or transport applications where the tarpaulin may experience friction or contact with other materials.

2.4. Durability and Longevity

PVC Tarpaulin has exceptional durability, with a long lifespan compared to other materials. When properly maintained, it can last for many years without significant wear or damage. Its resistance to weather elements like rain, wind, and sunlight contributes to its ability to withstand prolonged use, offering excellent value for money in the long term.

2.5. Flexibility and Ease of Handling

Despite its robust strength, PVC Tarpaulin remains highly flexible, making it easy to handle, fold, or manipulate without compromising its structural integrity. This flexibility makes it easier to transport and install, whether it’s being used as a covering for a large structure or a protective tarp for small equipment.

2.6. Chemical Resistance

PVC Tarpaulin is also resistant to a wide range of chemicals, including oils, acids, and solvents. This makes it an excellent choice for industrial applications where exposure to such substances is common. It helps protect both workers and equipment from damage caused by chemical spills or exposure, offering a versatile solution in various industries.

3. Types of PVC Tarpaulin

3.1. Based on Thickness (GSM - grams per square meter)

The thickness of PVC tarpaulin is often measured in GSM (grams per square meter), which indicates the material's weight and density. Generally, a higher GSM indicates a thicker and more durable tarpaulin. Thicker tarpaulins are better suited for heavy-duty applications, such as truck covers and industrial uses, while lighter GSM versions are used for less demanding applications like banners or temporary covers.

Lightweight (200-300 GSM): Ideal for temporary covers, tarps, and smaller protective applications.

Medium (400-600 GSM): Suitable for commercial uses, such as tarps for construction sites or boat covers.

Heavyweight (700-900 GSM): Best for industrial or transportation uses, where high durability and resistance to harsh conditions are essential.

3.2. Based on Denier (Thread Thickness)

Denier refers to the thickness of the threads used in the fabric base of PVC tarpaulin. A higher denier indicates stronger and thicker threads, which contribute to the overall strength and durability of the material. PVC tarpaulins with higher denier ratings are more resistant to tearing and abrasion, making them ideal for industrial and heavy-duty applications.

Low Denier (100-500 Denier): Suitable for lightweight applications with lower strength requirements.

Medium Denier (500-1000 Denier): Common in commercial and residential tarpaulins.

High Denier (1000+ Denier): Found in tarpaulins designed for heavy-duty, industrial uses requiring maximum strength and resistance.

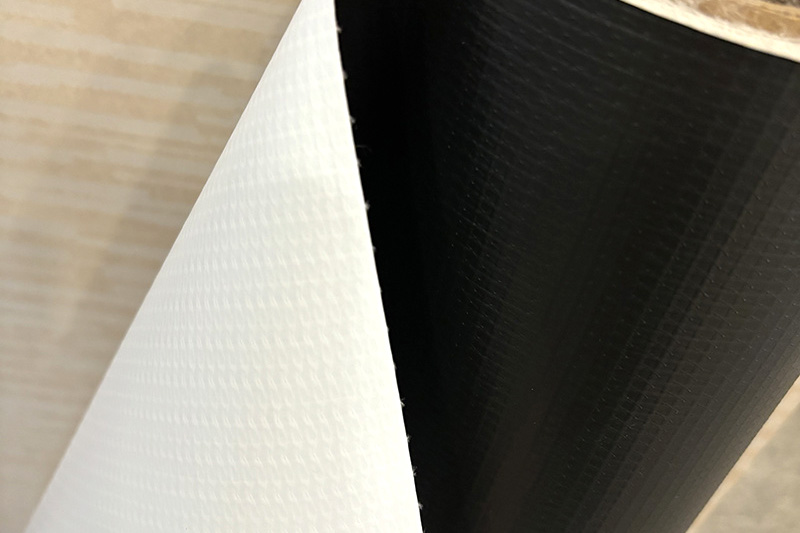

3.3. Different Colors and Finishes

PVC tarpaulins come in a wide range of colors, from standard white and blue to custom shades and prints. The color often depends on the intended use and visibility requirements. Some tarpaulins are designed to be highly reflective or to match specific branding colors, while others may feature camouflage or opaque designs for privacy.

Additionally, PVC tarpaulins can have different finishes, such as:

Glossy Finish: Provides a shiny surface and is easier to clean.

Matte Finish: Gives a more subdued look, often used for aesthetic purposes.

Opaque Finish: Blocks light transmission, offering privacy and protection from the sun.

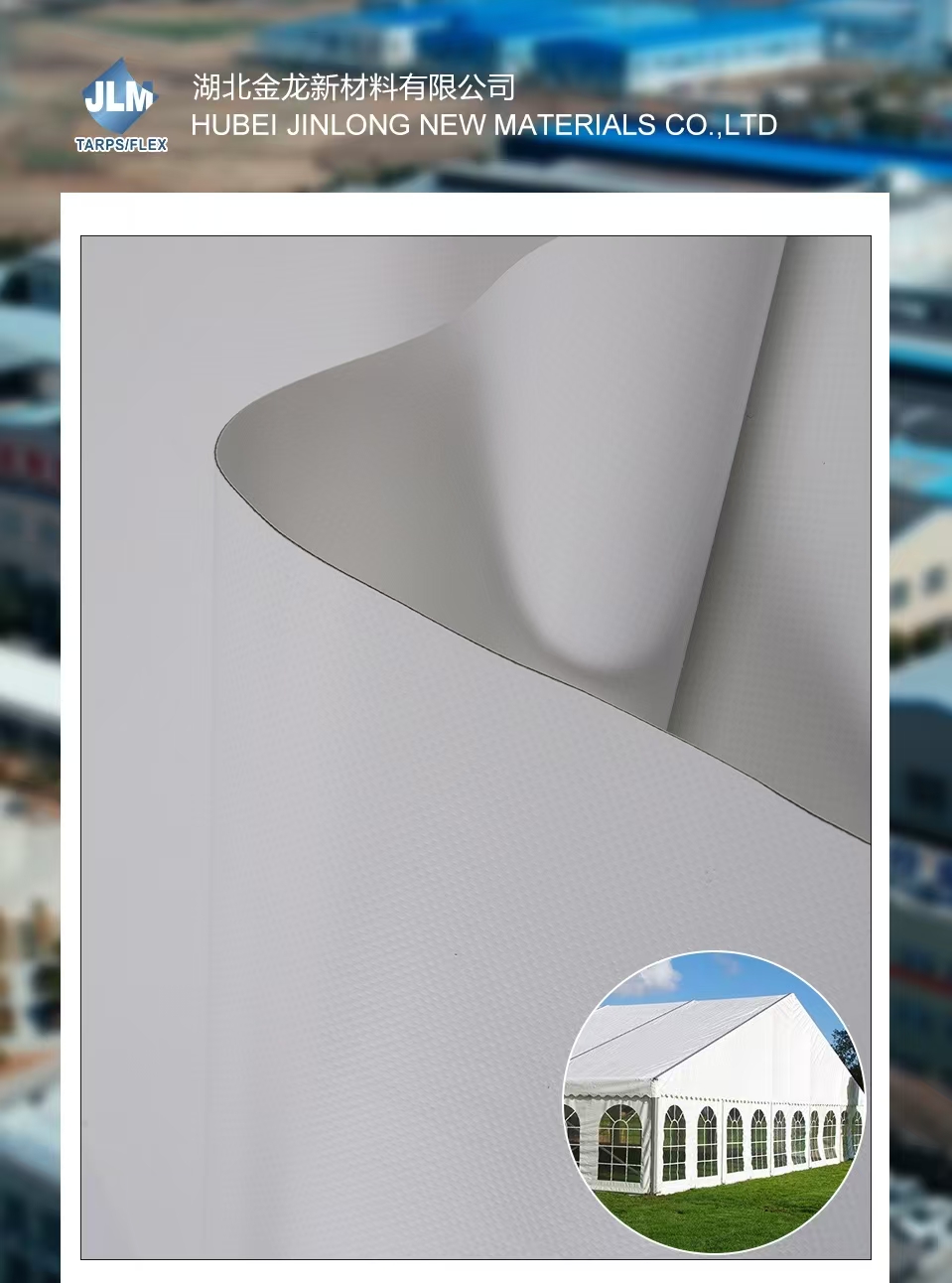

3.4. Coated vs. Laminated PVC Tarpaulin

Coated PVC Tarpaulin: Coating involves applying a thin layer of PVC over the fabric. This process typically results in a more flexible and lightweight material. Coated PVC tarpaulins are ideal for applications where flexibility and ease of handling are important, like in lightweight covers or smaller tarps.

Laminated PVC Tarpaulin: Laminating involves fusing two layers of PVC to the fabric, resulting in a more robust and durable material. Laminated PVC is often thicker and more resistant to abrasion and chemicals, making it ideal for heavy-duty applications like industrial covers, truck tarps, and large tents.

4. Applications of PVC Tarpaulin

4.1. Industrial Uses

PVC tarpaulin is widely used in industrial settings due to its strength, durability, and resistance to harsh environments. Common industrial applications include:

Storage Covers: Protecting machinery, equipment, and raw materials from dust, rain, and UV exposure.

Industrial Curtains: Used to partition workspaces, control dust, and maintain temperature in warehouses and factories.

Dust and Pollution Barriers: Common in construction and demolition sites to reduce airborne contaminants.

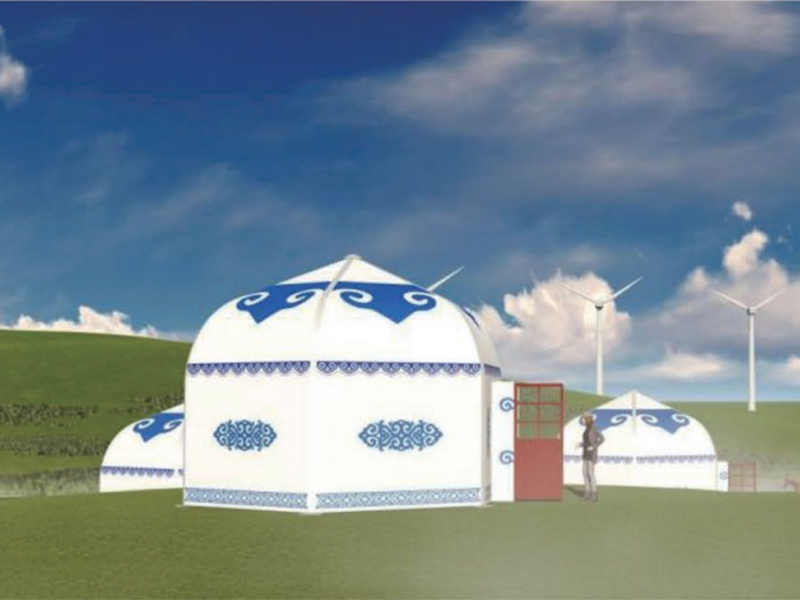

4.2. Commercial Uses

In commercial settings, PVC tarpaulin is often utilized for both practical and marketing purposes:

Advertising Banners: Durable and weather-resistant, PVC tarps are ideal for outdoor advertisements, billboards, and promotional displays.

Event Tents: PVC is frequently used to make high-quality tents for outdoor events like festivals, markets, and trade shows due to its resistance to rain and wind.

Temporary Shelters: For fairs, exhibitions, and construction sites, PVC tarpaulin provides easy-to-assemble, protective shelter.

4.3. Residential Uses

For homeowners and DIY enthusiasts, PVC tarpaulin offers various applications to protect property and maintain outdoor spaces:

Tarps for Landscaping: Protecting plants and outdoor furniture from the elements during extreme weather.

Car Covers: Lightweight yet durable PVC tarps provide a reliable solution for covering vehicles and protecting them from rain, snow, and dust.

Swimming Pool Covers: PVC tarps are used as pool covers to prevent debris from entering the water and to help maintain water temperature.

4.4. Transportation (Truck Covers, Boat Covers)

In transportation, PVC tarpaulin is essential for protecting goods, vehicles, and equipment during transit:

Truck Covers: PVC tarps are commonly used to cover loads on trucks, providing waterproof, UV-resistant protection to ensure the safe transportation of goods.

Boat Covers: Boats and marine equipment are exposed to water, salt, and UV rays, and PVC tarps offer effective protection against these elements, preventing corrosion and wear.

4.5. Construction and Agriculture

PVC tarpaulins play a vital role in protecting construction sites and agricultural fields:

Construction Site Covers: Protecting materials from the elements, including rain, wind, and sunlight. They are also used for dust containment and scaffolding covers.

Agricultural Covers: PVC tarps are used in agriculture for applications such as covering crops, silage, and farm equipment, as they provide protection against weather extremes and UV rays.

4.6. Awnings and Tents

PVC tarpaulins are frequently used in creating durable and weather-resistant awnings and tents for both commercial and residential use:

Awnings: Installed on homes, businesses, and outdoor patios to provide shade, rain protection, and enhance the aesthetic appeal.

Tents: Used for camping, festivals, and large outdoor events, PVC tarps provide durable, weatherproof shelters that resist tearing and UV damage.

5. How to Choose the Right PVC Tarpaulin

Selecting the right PVC tarpaulin is essential to ensure that it meets the specific needs of your application, providing optimal protection, durability, and cost-effectiveness. With a wide variety of PVC tarpaulins available—differing in thickness, weight, finish, and reinforcement—understanding key factors before purchasing can save time and money while maximizing performance. This section breaks down the most important considerations to guide you through the selection process.

5.1. Consider the Intended Use

The first and most critical step is to clearly define what the tarpaulin will be used for. The intended use determines many of the material properties you should prioritize:

Protection Level: Will the tarpaulin be used mainly for waterproofing, UV protection, dust and dirt coverage, or chemical resistance? For example, a truck cover requires full waterproofing and UV resistance, while an advertising banner may prioritize visual finish and lightweight flexibility.

Environment: Will the tarpaulin be exposed to harsh weather conditions like heavy rain, strong sun, or snow? Outdoor use demands higher durability, better UV resistance, and often heavier weights.

Duration of Use: Is the tarpaulin needed for a short-term project or long-term application? Temporary covers can often be lighter and less expensive, while long-term installations require stronger, more durable materials.

Load and Stress: Will the tarpaulin need to withstand wind pressure, mechanical abrasion, or chemical exposure? High-stress environments like construction sites need tougher materials with reinforced edges and stronger fabric bases.

By understanding the core requirements of your project, you can narrow down options more effectively.

5.2. Choose the Right Size and Dimensions

Tarpaulins come in many sizes and can also be custom cut to specific dimensions. Selecting the right size involves:

Coverage Needs: Measure the area or object to be covered accurately, factoring in some extra length for securing the tarp (e.g., wrapping edges, tying ropes).

Shape: Rectangular or square tarps are standard, but sometimes custom shapes are needed for uneven or irregular loads.

Weight Considerations: Larger tarpaulins can become heavy and difficult to handle if the material is thick or heavyweight. Make sure the size combined with weight is manageable for installation and removal.

Ordering a tarp too small defeats the purpose of protection, while one that is too large can cause handling problems and material waste.

5.3. Thickness and Weight (GSM) Matter

The thickness of PVC tarpaulin is typically measured in grams per square meter (GSM) and plays a crucial role in performance:

Lightweight Tarps (200–300 GSM): These are easier to handle and less expensive, ideal for temporary covers, event tents, and light protection. However, they offer less resistance to tears and abrasion.

Medium Weight Tarps (400–600 GSM): A balanced choice for many commercial and residential uses, providing better durability while remaining relatively flexible.

Heavyweight Tarps (700 GSM and above): Designed for industrial applications, such as truck covers, construction site protection, and heavy-duty agriculture use. They provide maximum durability, resistance to wear, and longevity.

Choosing the right thickness depends largely on how tough and durable the tarpaulin needs to be and how much weight you can practically manage.

5.4. Color and Appearance

Though functionality is paramount, color and finish often influence the choice of PVC tarpaulin:

Color Coding: Different colors can serve different purposes, such as visibility, branding, or camouflage. For example, bright colors like orange or red improve visibility and safety on construction sites, while green or brown may be preferred in agricultural or forestry settings.

Aesthetics: For applications such as event tents or awnings, the appearance matters. Glossy finishes provide a shiny, attractive look and are easier to clean, while matte finishes offer a more understated, professional appearance.

Heat Reflection: Light-colored tarps tend to reflect sunlight, keeping covered items cooler, whereas darker tarps absorb heat.

Custom Printing: Some suppliers offer printing options for logos, advertisements, or custom designs on PVC tarps used for marketing or commercial purposes.

Selecting the right color and finish can improve the effectiveness of the tarp for specific roles beyond basic protection.

5.5. Special Features and Reinforcements

To enhance performance and usability, many PVC tarpaulins come with special features that can be critical depending on the application:

Reinforced Edges: Double-stitched or heat-welded edges improve strength and prevent fraying, which is essential for long-term or heavy-duty use.

Grommets/Eyelets: Metal eyelets or reinforced holes along the edges allow for secure fastening with ropes, bungees, or hooks. The spacing, size, and material of these grommets matter for durability and ease of installation.

Welded Seams: Some tarpaulins use heat welding instead of stitching to create seams that are fully waterproof and stronger.

UV and Fire Retardant Coatings: Additional chemical treatments can improve UV resistance or provide flame retardant properties, which are critical for outdoor uses and safety regulations.

Anti-Mold and Anti-Fungal Treatments: Especially useful in humid or wet environments to prevent mildew and degradation.

These features increase the upfront cost but often result in longer service life and better performance.

5.6. Coated vs. Laminated PVC Tarpaulin

Understanding the difference between coated and laminated PVC tarpaulins helps match the material’s construction to your needs:

Coated PVC Tarpaulin: Involves applying a single layer of PVC coating on a polyester fabric base. This makes the material lighter and more flexible, suitable for applications needing easy handling and moderate protection.

Laminated PVC Tarpaulin: Has multiple layers of PVC fused together with the fabric in between. This results in a thicker, more robust material with higher resistance to tears, chemicals, and abrasion—ideal for heavy-duty industrial and transportation uses.

Choose laminated tarps when maximum durability is required, and coated tarps for lighter-duty, easier-to-handle applications.

5.7. Budget and Cost-Effectiveness

Cost is always a consideration, but it’s important to balance initial investment with longevity and performance:

Cheaper tarps may seem attractive upfront but can wear out faster, requiring more frequent replacements.

Investing in higher quality, more durable PVC tarpaulins can reduce total cost of ownership by minimizing repairs and replacements.

Consider the warranty and service support from suppliers, which can add value and peace of mind.

5.8. Supplier and Customization Options

Finally, choosing a reliable supplier and considering customization can improve satisfaction:

Look for suppliers who provide detailed technical specifications, samples, and quality certifications.

Many manufacturers offer custom sizes, colors, reinforcements, and printing options to fit exact requirements.

Good after-sales support and availability of accessories (ropes, fasteners) can simplify installation and maintenance.

Choosing the right PVC tarpaulin involves a careful balance between intended use, size, thickness, color, special features, and budget. By assessing the environment, expected wear and tear, and functional needs upfront, you can select a tarpaulin that delivers reliable, long-lasting protection without unnecessary expense.

6. PVC Tarpaulin Accessories and Installation

When it comes to installing and maintaining PVC tarpaulins, having the right accessories is just as crucial as choosing the right material. Accessories like eyelets, ropes, bungees, and tie-downs ensure secure installation, while proper welding and repair techniques ensure the longevity of the tarp. This section will guide you through the essential accessories and installation practices for PVC tarpaulins, ensuring that they perform optimally.

6.1. Types of Eyelets and Fasteners

Eyelets (also known as grommets) are one of the most common and essential accessories for PVC tarpaulins. They provide reinforcement at the edges of the tarp, allowing for easy attachment and secure fastening. The correct choice of eyelets can significantly impact the tarp’s performance, durability, and ease of installation.

Standard Eyelets: These are the most common type and are made of metal or plastic. They are ideal for light to medium-duty applications and come in various sizes to suit different rope diameters. Standard eyelets are perfect for tarps that don’t need to bear heavy loads but require basic fastening.

Heavy-Duty Eyelets: For industrial or construction-related tarpaulins, heavy-duty eyelets are recommended. These eyelets are made from stronger metals like stainless steel and have reinforced backing to handle higher stress loads. They are suitable for tarps that will be exposed to heavy winds, pressure, or harsh environmental conditions.

Reinforced Eyelets: These eyelets feature additional fabric reinforcement around the hole to prevent wear and tear. For long-term or frequent-use tarpaulins, reinforced eyelets help maintain structural integrity, reducing the risk of the eyelets pulling out or the material tearing around the grommet.

PVC-Coated Eyelets: For specific applications, especially in environments with high corrosion or chemical exposure, PVC-coated eyelets are ideal. These eyelets are coated with a protective PVC layer, which helps prevent rusting and corrosion, making them perfect for use in marine, agricultural, or chemical industries.

The eyelets’ spacing is also critical to ensure the even distribution of stress across the tarp. Generally, eyelets are spaced 30-50 cm apart along the edges, but the spacing should be adjusted according to the size of the tarp and the expected wind or load conditions.

6.2. Ropes, Bungees, and Tie-Downs

Once eyelets are in place, securing the tarp requires the right type of ropes, bungees, or tie-downs. These accessories ensure that the tarp stays in place even during adverse weather conditions. Here’s a look at the most common methods of fastening PVC tarpaulins:

Ropes: Heavy-duty ropes, often made of nylon, polyester, or polypropylene, are commonly used for securing PVC tarpaulins. They offer the advantage of being versatile and adjustable, allowing for a tight fit. When using ropes, always ensure that they are tied securely to the eyelets and use knots that won’t come undone in high winds, such as the bowline knot. It’s also important to use ropes of appropriate length to ensure that you can fully secure the corners and edges of the tarp.

Bungee Cords: Bungee cords are elastic and offer a flexible solution for securing tarps, especially in environments where quick adjustments may be needed. They can be easily stretched over the tarpaulin, allowing for a tight and secure fit. Bungee cords are commonly used for temporary applications or when the tarp needs to be adjusted or removed frequently, such as during outdoor events or temporary covers.

Tie-Down Straps: For heavy-duty applications, such as securing tarps over cargo or large equipment, tie-down straps provide superior strength and reliability. These straps are typically made of polyester or nylon and feature a ratchet mechanism to tighten the straps securely. Tie-down straps are ideal for use in trucking, transportation, or any situation where a high level of tension is required to keep the tarp in place.

Cam Buckle Straps: Similar to ratchet straps but easier to adjust, cam buckle straps are useful for securing tarpaulins on equipment or vehicles. They are easier to use than ratchet straps, as they don’t require as much force to tighten, making them suitable for medium-duty applications.

6.3. Welding and Repair Techniques

Over time, PVC tarpaulins can develop tears or punctures due to harsh weather, abrasion, or wear. It’s essential to have the right tools and techniques for repairing these damages to extend the life of the tarp. Here are some methods for welding and repairing PVC tarpaulins:

Welding: PVC tarpaulins can be welded using heat sealing or hot air welding techniques. These processes involve using a heat source to melt the edges of the PVC material, allowing them to fuse together. Heat welding ensures a watertight, strong bond and is ideal for repairing large sections of the tarp.

Hot Air Welding: This technique uses hot air to melt the PVC edges, which are then pressed together to form a solid seal. This method is commonly used in industrial-grade PVC tarpaulins and requires specialized welding machines.

Heat Sealing: For smaller repairs, heat sealing can be done using a handheld heat sealer. The edges of the tarp are placed together and heated until the PVC begins to melt, and then pressure is applied to bond the material. Heat sealing is typically used for smaller patches or seams but is highly effective for ensuring waterproof repairs.

Patch Kits: PVC patch kits are available for repairing smaller holes or tears in tarpaulins. These kits typically come with PVC patches, adhesive, and cleaning materials. To use a patch kit:

Clean the damaged area thoroughly to remove dirt, oils, and debris.

Cut a patch slightly larger than the hole or tear.

Apply the adhesive and attach the patch to the damaged area, pressing it firmly to ensure proper bonding.

Allow the adhesive to dry completely before reusing the tarp.

PVC Repair Tape: For quick and temporary repairs, PVC tarpaulin repair tape is an easy and effective solution. Simply apply the tape over the tear, ensuring that it covers the entire damaged area. This method works best for minor tears and small punctures and can provide a temporary fix until you can carry out a more permanent repair.

Gluing: PVC adhesives or glues are sometimes used for repairs, especially if welding is not feasible. Specialized PVC glue is used to bond the torn edges of the tarp, and although it can be effective, it typically doesn’t provide the same long-term durability as welding or patching.

6.4. Installation Tips

Installing PVC tarpaulins requires attention to detail to ensure that they perform optimally and remain secure in the long term. Below are some key installation tips:

Preparing the Installation Area: Before setting up a PVC tarpaulin, make sure the installation area is clear of debris, sharp objects, or anything that could puncture or damage the tarp. If the tarp is going to be placed over sensitive equipment or surfaces, consider using a layer of padding underneath to prevent abrasion.

Proper Tensioning: When securing a PVC tarp, it is important to ensure it is tightly pulled across the intended area. A loose tarp can flap in the wind, leading to potential wear and tear or loss of effectiveness. However, avoid over-tightening, as this could cause the tarp to tear or the fasteners to strain.

Anchor Points: Always secure the tarp at multiple anchor points to ensure even tension across the surface. This helps prevent wind from lifting the tarp and causing damage.

Regular Checks and Maintenance: Even the best-installed PVC tarpaulins need regular inspection, especially after heavy weather. Look for signs of wear, stress on the eyelets, or any damage that may have occurred. Early detection of issues allows for prompt repairs, reducing the need for more costly replacements.

6.5. Maintenance of Accessories

Accessories like ropes, bungees, and straps also require maintenance to ensure they remain functional:

Cleaning: Regularly clean the ropes and straps to remove dirt, mud, or chemicals. Dirt buildup can degrade the fibers over time, weakening their strength.

Checking for Wear: Inspect the eyelets, ropes, and tie-downs for any signs of wear, rust, or fraying. If you notice any damage, replace the component immediately to avoid further complications.

Storage: When not in use, store the PVC tarpaulin and accessories in a cool, dry place. UV exposure and extreme temperatures can weaken the material and its accessories.

Choosing the right accessories and properly installing PVC tarpaulins are critical to maximizing their performance and longevity. By selecting the appropriate eyelets, ropes, bungees, and tie-downs, and employing effective repair techniques, you can ensure that your tarp remains durable, secure, and efficient for its intended purpose. Whether for industrial, commercial, or residential use, proper installation and maintenance are key to extending the life of your PVC tarpaulin.

7. Maintenance and Care Tips for PVC Tarpaulin

Proper maintenance and care are vital to prolong the life of PVC tarpaulins and ensure they perform effectively over time. Despite their durability and resistance to harsh environments, PVC tarps can suffer damage from dirt buildup, environmental exposure, or mechanical wear if not maintained well. This section offers a comprehensive guide on how to clean, store, and repair your PVC tarpaulin to maximize its lifespan and keep it in top condition.

7.1 Cleaning PVC Tarpaulin

Regular cleaning removes dirt, grime, pollutants, and biological growth (like mold and mildew) that can degrade the PVC coating and fabric backing. Proper cleaning not only enhances appearance but also preserves material integrity.

Why Cleaning Matters

Dirt and Dust Accumulation: Dust particles combined with moisture can become abrasive, gradually wearing down the surface.

Mold and Mildew Growth: In damp or humid conditions, mold and mildew can develop on the surface or underside of the tarp, causing discoloration and potentially weakening the material.

Chemical Deposits: In industrial or agricultural environments, exposure to chemicals or fertilizers can leave residues that degrade the PVC over time.

UV Protection: Cleaning removes surface contaminants that can reduce the effectiveness of UV-resistant coatings.

Cleaning Frequency

The frequency depends on the usage environment:

Heavy-duty or industrial use: Clean every 1-3 months.

Outdoor residential or commercial use: Clean every 3-6 months.

Indoor or light-use tarps: Clean as needed, generally twice a year.

Step-by-Step Cleaning Process

Preparation: Remove loose debris such as leaves, twigs, or dirt using a soft broom or brush. Avoid sharp or abrasive tools that might scratch the surface.

Rinse with Water: Use a garden hose or low-pressure washer to wet the tarp. This helps loosen dirt and prevents scratching during scrubbing.

Use Mild Detergent: Mix a solution of warm water and a mild, non-abrasive detergent or soap (e.g., dishwashing liquid). Avoid harsh chemical cleaners, solvents, or bleach, as these can damage the PVC layer.

Scrub Gently: Using a soft-bristle brush or sponge, scrub the tarp gently in circular motions. Focus on areas with heavy staining or mold. Do not use wire brushes or abrasive pads, which can damage the coating.

Rinse Thoroughly: Rinse off all soap residues with clean water. Soap residues left on the tarp can attract dirt or cause surface degradation over time.

Dry Properly: Allow the tarp to air dry completely before folding or storing. Avoid direct sunlight drying for long periods, as excessive UV exposure can cause fading over time.

Dealing with Mold and Mildew

For stubborn mold or mildew, you can use a mixture of equal parts water and white vinegar, or a specialized mold remover safe for PVC materials. Apply the solution, let it sit for 10-15 minutes, then scrub and rinse thoroughly. Always test any cleaning solution on a small, inconspicuous area first.

Tips to Avoid Damage During Cleaning

Never use bleach or abrasive chemicals.

Avoid high-pressure washers set at too high a PSI; they can erode the PVC coating.

Don’t scrub too aggressively to prevent surface scratches or tears.

If your tarp has printed logos or graphics, clean gently to avoid damaging the print.

7.2 Storage Best Practices

How you store your PVC tarpaulin when not in use significantly impacts its lifespan. Poor storage can lead to mold growth, creases, cracks, or loss of flexibility.

Ideal Storage Conditions

Cool and Dry Environment: Store the tarp in a cool, dry place away from direct sunlight, moisture, and extreme temperatures. UV exposure during storage can degrade PVC, and dampness promotes mold.

Clean Before Storing: Always clean the tarp thoroughly before folding and storing. Dirt and moisture trapped in folds can accelerate damage.

Avoid Folding Creases: Try to fold the tarp along natural fold lines or roll it to prevent creating sharp creases that may weaken the material over time. Rolling is preferable for longer storage durations.

Protect from Pests: Store tarps in sealed containers or bags to protect them from rodents, insects, or other pests that might chew or damage the fabric.

Storage Tips

Use tarpaulin storage bags or heavy-duty plastic containers for protection.

If rolling, secure the roll with straps or ties to maintain compactness.

Label storage containers for easy identification.

Avoid placing heavy objects on top of stored tarps to prevent deformation or permanent creasing.

Avoid Prolonged Storage Under Tension

Never store tarps tightly stretched or secured under tension for extended periods, as this can cause distortion or weakening of the material.

7.3 Repairing Tears and Damage

Even with careful handling, PVC tarpaulins may suffer tears, punctures, or seam damage. Timely and proper repairs can restore waterproofness, strength, and usability, preventing minor damage from escalating.

Types of Common Damage

Small Punctures or Holes: Caused by sharp objects or abrasion.

Tears or Rips: Larger cuts often due to wind stress or improper handling.

Seam Failures: Seams may separate due to aging, poor initial welding, or stress.

Edge Damage: Frayed or torn edges from constant wear or improper fastening.

Repair Methods

Using PVC Patch Kits

These kits usually include PVC patches, adhesive, and cleaning materials. The procedure is:

Clean the Damaged Area: Remove dirt and dry thoroughly.

Cut Patch to Size: Ensure the patch extends at least 5 cm beyond the damage on all sides.

Apply Adhesive: Spread the adhesive evenly on the patch and the tarp.

Press Patch Firmly: Apply pressure for several minutes to ensure a tight bond.

Allow to Cure: Let the adhesive dry as per manufacturer instructions before using the tarp.

Heat Welding

For more durable repairs, especially on larger tears or seam issues, heat welding is preferred:

Prepare the Edges: Clean and trim ragged edges.

Heat the Welding Tool: Use a hot air gun or specialized welding machine.

Fuse the Material: Press edges together while applying heat to bond the PVC layers.

Cool and Test: Allow to cool fully before flexing or using the tarp.

PVC Repair Tape

A fast and temporary fix for small holes or tears is applying PVC repair tape. Clean and dry the area first, then apply the tape firmly with some overlap around the damage.

Sewing and Reinforcement

Sewing is generally not recommended for PVC tarps because needle holes can compromise waterproofness. However, reinforced edges or patches can sometimes be sewn and then heat sealed or taped over for waterproofing.

Preventative Repair Tips

Inspect your tarp regularly for early signs of wear.

Address small holes or tears immediately before they worsen.

Reinforce vulnerable areas like edges or corners with extra patches.

Avoid sharp tools or dragging the tarp over rough surfaces to minimize damage.

Proper maintenance and care of PVC tarpaulins involve regular and gentle cleaning, appropriate storage, and timely repairs. By following the right cleaning procedures, storing tarps in optimal conditions, and using effective repair techniques, you can significantly extend the life and functionality of your PVC tarpaulin. These efforts protect your investment and ensure the tarp continues to deliver waterproofing, weather resistance, and durability for years to come.

PVC tarpaulins are versatile, durable, and cost-effective materials widely used across industrial, commercial, residential, and transportation sectors due to their outstanding features such as waterproofing, UV resistance, tear and abrasion strength, chemical resistance, and ease of handling. Their performance and longevity, however, depend greatly on proper installation, the right choice of accessories like eyelets, ropes, and tie-downs, and diligent maintenance practices. Selecting appropriate eyelets tailored to the application’s stress levels ensures secure fastening and prevents premature wear, while using suitable ropes or bungee cords maintains tension and stability under varying environmental conditions. Furthermore, effective repair methods, including heat welding, patching, and use of repair tapes, allow for timely restoration of damaged tarpaulins, preventing minor issues from escalating and prolonging service life. Equally important is regular cleaning with mild detergents to remove dirt, mold, and chemical residues that could degrade the PVC surface, and proper storage in cool, dry places, ideally rolled and protected from pests and UV exposure, which prevents creases, cracks, and microbial growth. Attention to these factors not only preserves the functional and aesthetic qualities of PVC tarps but also enhances their cost-effectiveness by reducing replacement frequency and downtime. By following comprehensive maintenance routines and selecting suitable accessories for installation, users can fully leverage the inherent advantages of PVC tarpaulin, making it a reliable and sustainable solution for a wide range of protective covering needs in diverse environments.

English

English русский

русский Français

Français Español

Español