What methods are used to apply the PVC coating to the base fabric?

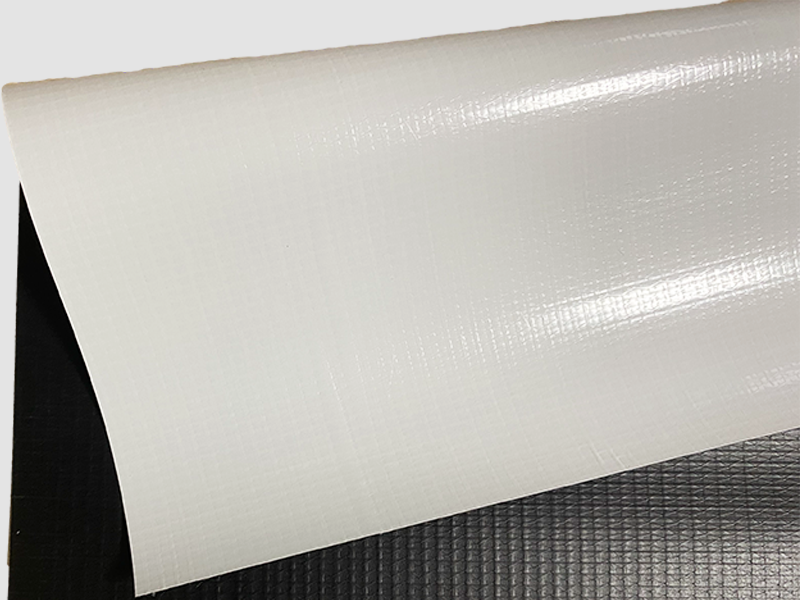

The PVC coating is typically applied to the base fabric of

PVC Tensile Tent Fabric using one of several common methods. These methods ensure proper adhesion and uniform coverage of the PVC coating onto the fabric substrate. Some of the most commonly used methods include:

Knife Coating: In knife coating, the PVC paste or liquid is applied to the surface of the base fabric using a knife-like applicator. The fabric passes under the knife, which spreads the PVC coating evenly across its surface. The thickness of the coating can be adjusted by controlling the gap between the knife and the fabric. After coating, the fabric passes through a curing or drying process to solidify the PVC coating.

Dip Coating: Dip coating involves immersing the base fabric into a tank or vat filled with PVC dispersion or solution. The fabric is passed through the coating bath, allowing the PVC coating to penetrate the fabric fibers and adhere to the surface. Excess coating is typically removed by passing the fabric through squeeze rollers or doctor blades before undergoing a drying or curing process to solidify the PVC coating.

Calendering: Calendering is a mechanical process that involves passing the base fabric and PVC paste or compound through a series of heated rollers. The rollers compress and stretch the PVC coating, forcing it into the fabric fibers and forming a thin, uniform layer on the surface. Calendering can be used to produce PVC tent fabric with precise thickness and smooth surface finishes.

Extrusion Coating: Extrusion coating is a continuous process where molten PVC resin is extruded through a die onto the surface of the base fabric. The fabric passes under the extrusion die, and the molten PVC forms a coating as it cools and solidifies on contact with the fabric. Extrusion coating is often used for producing PVC tent fabric with waterproof and durable coatings.

Spray Coating: Spray coating involves spraying the PVC dispersion or solution onto the surface of the base fabric using spray nozzles or guns. The PVC coating is atomized into fine droplets, which are deposited onto the fabric surface to form a uniform layer. Spray coating allows for precise control over the coating thickness and coverage and is suitable for producing PVC tent fabric with specialized finishes or patterns.

These methods may vary depending on factors such as the desired thickness and properties of the PVC coating, the type of base fabric used, and the specific requirements of the application. Each method has its advantages and limitations in terms of cost, efficiency, and the quality of the final PVC tent fabric produced.

Can it be used for both commercial and residential purposes?

PVC tent fabric can be used for both commercial and residential purposes due to its versatility, durability, and weather-resistant properties. Here's how it can be utilized in each context:

Commercial Purposes:Event Tents: PVC tent fabric is commonly used for commercial event tents, such as those used for weddings, trade shows, festivals, and corporate events. These tents provide temporary shelter and can accommodate large gatherings of people. PVC tent fabric offers excellent weather protection, allowing events to proceed even in inclement weather conditions.

Hospitality Industry: In the hospitality industry,

PVC Tent Tarpaulin Material is used to create outdoor dining areas, lounge spaces, and recreational facilities for hotels, resorts, and restaurants. These structures provide guests with comfortable and functional outdoor spaces while complementing the aesthetic and ambiance of the property.

Commercial Canopies: PVC tent fabric is used to construct commercial canopies and shade structures for businesses, such as outdoor seating areas for cafes, retail storefronts, car dealerships, and recreational facilities. These structures offer protection from the sun, rain, and wind while enhancing the visual appeal of the property.

Residential Purposes:Residential Tents: PVC tent fabric can be used to create residential tents or temporary structures for backyard events, camping trips, and recreational activities. These tents offer homeowners a versatile and portable shelter solution for hosting outdoor gatherings, backyard barbecues, or relaxing in the garden.

Patio Covers: PVC tent fabric is utilized to construct patio covers, pergolas, and shade sails for residential properties. These structures provide shade and protection from the elements, allowing homeowners to enjoy their outdoor living spaces year-round.

PVC Tent Material offers customizable design options to complement the architectural style of the home and enhance outdoor aesthetics.

Pool Enclosures: PVC tent fabric can be used to create pool enclosures and sunrooms for residential swimming pools. These enclosures offer protection from debris, insects, and harsh UV rays while extending the swimming season and providing a comfortable environment for relaxation and recreation.

Whether for commercial or residential purposes, PVC tent fabric offers a cost-effective, durable, and customizable solution for creating temporary or permanent shelter structures that meet the needs and preferences of users. Its flexibility, weather resistance, and ease of installation make it an ideal choice for a wide range of applications in both settings.

English

English русский

русский Français

Français Español

Español