What type of PVC material is used in the construction of onion water tanks?

In the construction of

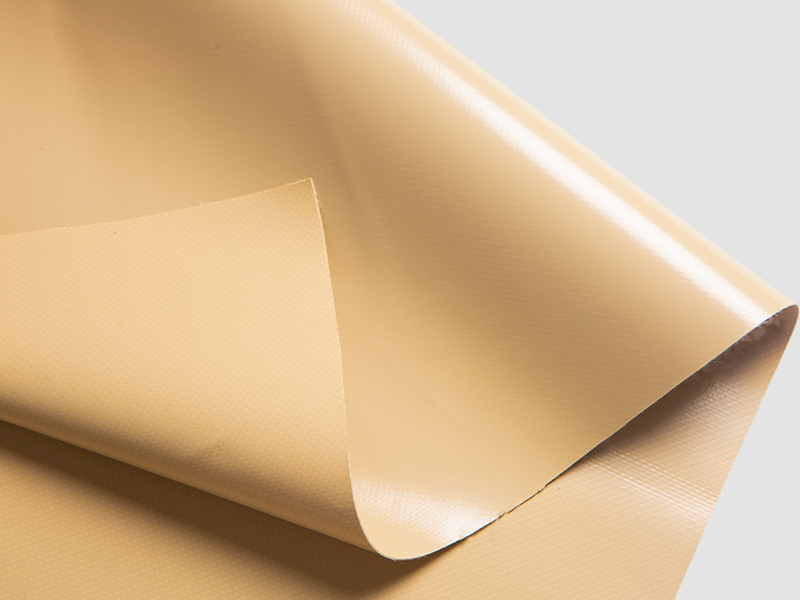

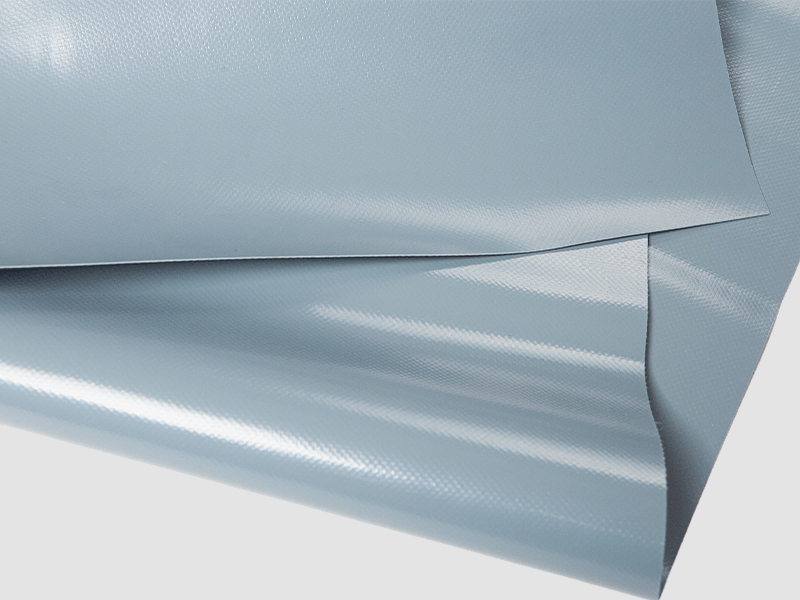

onion water tanks, flexible PVC (polyvinyl chloride) material is typically used. This PVC material is specifically formulated and manufactured to meet the requirements for water storage applications. Here are some key characteristics of the PVC material used in onion water tanks:

Food-Grade PVC: The PVC material used in onion water tanks is often food-grade, meaning it meets strict safety and quality standards for contact with potable water. It is designed to be non-toxic and safe for storing drinking water without imparting any harmful substances.

Flexible and Durable: PVC material used in onion water tanks is flexible yet durable, allowing the tank to expand and contract as water is filled and emptied. This flexibility ensures that the tank can withstand varying water volumes and environmental conditions without cracking or rupturing.

UV Stabilized: To enhance durability and longevity, the PVC material may be UV stabilized to resist degradation from sunlight exposure. UV stabilization helps prevent the material from becoming brittle or discolored over time, ensuring the tank maintains its integrity even when exposed to outdoor conditions.

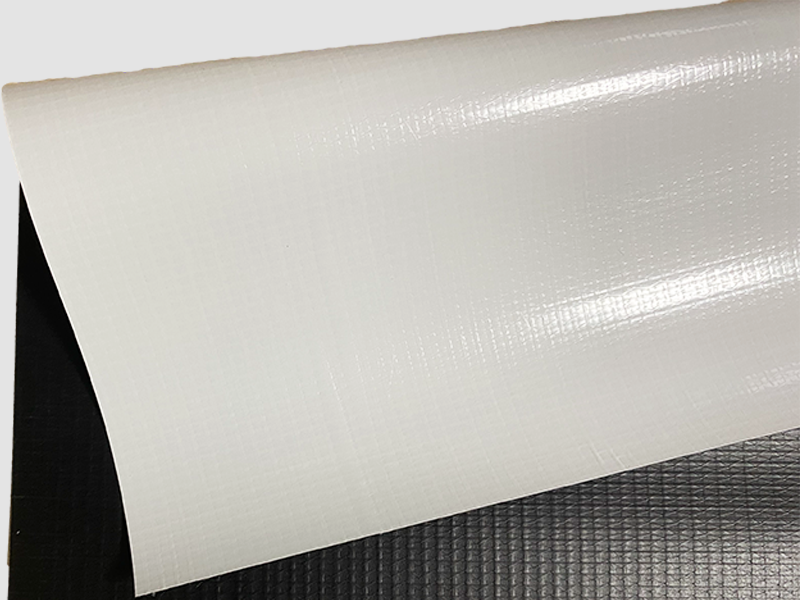

Reinforced Fabric: In some cases, the PVC material may be reinforced with polyester or other high-strength fibers to enhance its tear resistance and tensile strength. Reinforced PVC fabric provides additional structural support, making the tank more robust and resilient against punctures and abrasion.

Weldable: PVC material used in onion water tanks is weldable, allowing seams to be securely bonded together during the manufacturing process. High-frequency welding, heat sealing, or radio frequency welding techniques are commonly employed to create strong, watertight seals along the edges of the tank.

Chemical Resistance: PVC material exhibits excellent resistance to a wide range of chemicals, including acids, alkalis, and oxidizing agents. This chemical resistance helps prevent the PVC tank from deteriorating or reacting with the stored water, ensuring water quality and safety.

The PVC material used in onion water tanks is chosen for its suitability for water storage applications, offering a combination of flexibility, durability, safety, and chemical resistance to meet the needs of various industries and sectors.

How is the PVC fabric reinforced to ensure durability and strength?

The

PVC onion water tank used in onion water tanks is often reinforced to enhance its durability and strength, ensuring the tank can withstand the stresses and pressures associated with water storage. Here are some common methods used to reinforce PVC fabric:

Polyester Fabric Reinforcement: One of the most common reinforcement methods involves laminating or coating the PVC fabric with polyester fibers. These fibers are woven into the fabric or applied as a separate layer, providing added tensile strength and tear resistance. The polyester reinforcement helps prevent the PVC fabric from stretching or tearing under pressure, improving the overall durability of the tank.

High-Tensile Strength Fibers: In addition to polyester, other high-tensile strength fibers such as nylon or aramid (e.g., Kevlar) may be used to reinforce the PVC fabric. These fibers are known for their exceptional strength-to-weight ratio and can significantly enhance the structural integrity of the tank.

Multiple Layers: Some PVC fabrics are constructed with multiple layers, with each layer serving a specific purpose. For example, a base layer of PVC may be reinforced with a layer of polyester fabric for added strength, while an outer layer of UV-resistant PVC provides protection against sunlight and environmental factors. Multiple layers help distribute stress more evenly throughout the fabric, reducing the likelihood of failure or damage.

Bonding Techniques: The reinforcement materials are securely bonded to the PVC fabric using heat-sealing, welding, or adhesive bonding techniques. High-frequency welding or radio frequency welding is commonly used to create strong, watertight seals between the PVC and reinforcement layers. These bonding techniques ensure that the reinforcement materials remain securely attached to the PVC fabric, even under dynamic loading conditions.

Coating or Lamination: In some cases, the PVC fabric may be coated or laminated with a layer of protective material to enhance its durability and resistance to abrasion, chemicals, and UV radiation. The coating or lamination process adds an additional barrier to the fabric, prolonging its lifespan and maintaining its structural integrity over time.

English

English русский

русский Français

Français Español

Español