What are the weight, thickness, and translucency options available for these banners?

PVC backlit flex banners come in various weight, thickness, and translucency options to suit different applications and printing preferences. Here's an overview of the typical range:

Weight: PVC backlit flex banners can vary in weight depending on the specific requirements of the application. Common weights for these banners typically range from around 250 to 600 grams per square meter (gsm). Lighter-weight banners are easier to handle and may be more cost-effective, while heavier-weight banners offer increased durability and stability, particularly in outdoor environments.

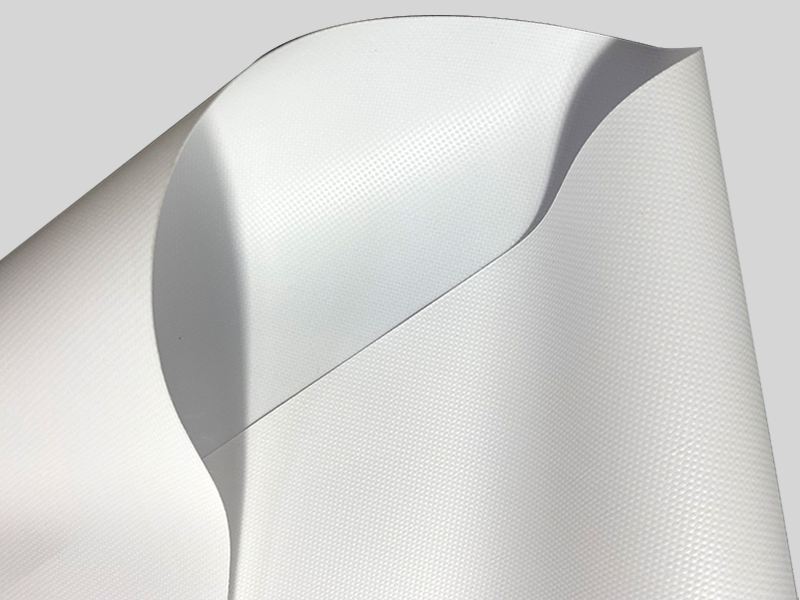

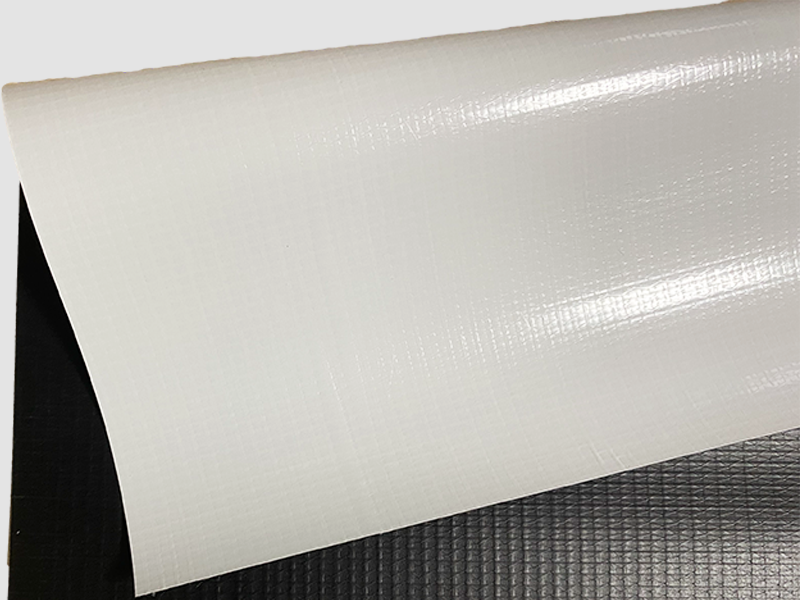

Thickness: The thickness of PVC backlit flex banners is measured in mils or microns, with typical thicknesses ranging from around 10 mils (0.25 mm) to 20 mils (0.5 mm). Thicker banners generally provide better tear resistance and durability, especially for outdoor installations where they may be subjected to wind stress and other environmental factors. However, thinner banners can offer advantages in terms of flexibility and ease of installation.

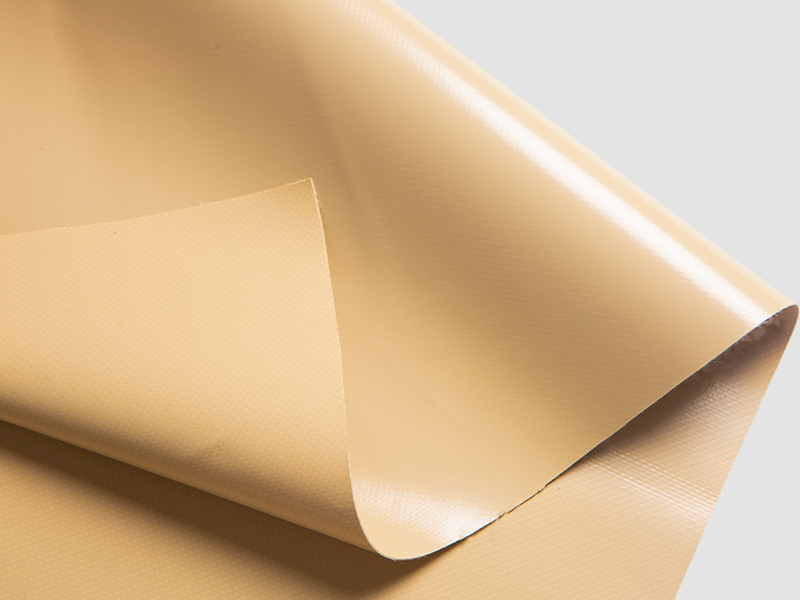

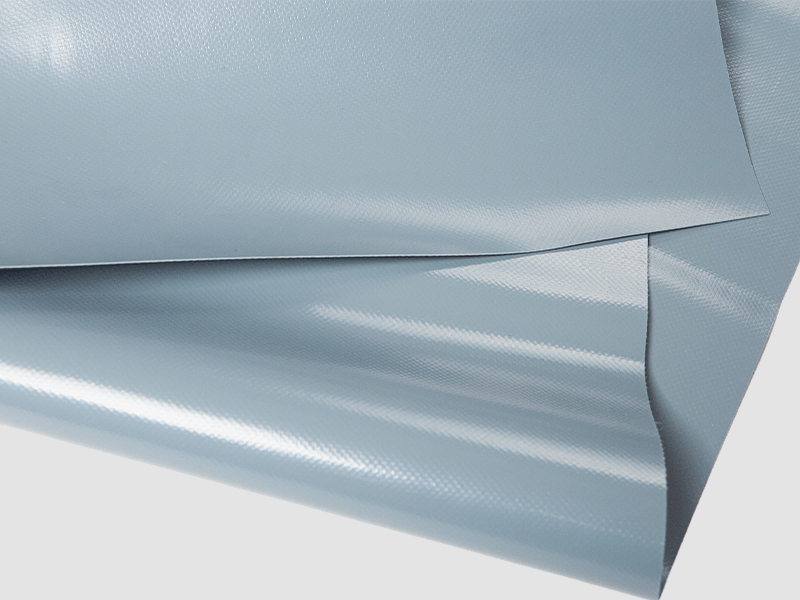

Translucency: Translucency refers to the degree to which light can pass through the banner material, affecting the brightness and uniformity of illumination in backlit displays. PVC backlit flex banners are designed to be translucent, allowing light from behind to illuminate the printed graphics effectively. The level of translucency can vary depending on factors such as material composition, thickness, and surface finish. Generally, these banners are engineered to provide optimal light diffusion while maintaining vibrant colors and sharp image quality.

How does the composition affect light diffusion and print quality?

The composition of

PVC backlit flex banners plays a significant role in determining both light diffusion and print quality. Here's how different aspects of composition can impact these factors:

Material Translucency: The translucency of the PVC material directly affects its ability to diffuse light evenly across the surface of the banner. A more translucent material allows light to pass through more readily, resulting in better illumination of the printed graphics. This is crucial for achieving uniform brightness and preventing hotspots or shadowing in backlit displays.

Surface Finish: The surface finish of the PVC backlit flex banner can also influence light diffusion and print quality. A smooth surface tends to produce more even light distribution and sharper image reproduction, as it minimizes light scattering and distortion. Textured or matte finishes may scatter light more diffusely, which can be advantageous for reducing glare and enhancing viewing angles but may slightly soften image details. The choice of surface finish depends on factors such as the intended viewing distance, lighting conditions, and aesthetic preferences.

Color Saturation and Opacity: The color saturation and opacity of the PVC material can impact the vibrancy and depth of colors in the printed graphics. A more opaque material may provide better color saturation by blocking out background light and enhancing contrast with the illuminated areas. However, excessive opacity can also reduce the overall brightness of the backlit display. May adjust the formulation of the PVC material to achieve the optimal balance between opacity and translucency, ensuring vibrant colors without compromising light diffusion.

Ink Compatibility: The composition of the PVC material can affect its compatibility with different types of printing inks, which in turn can influence print quality. Some PVC backlit flex banners are specifically engineered for use with solvent-based, UV-curable, latex, or dye sublimation inks. Using the appropriate ink type for the substrate is crucial for achieving optimal adhesion, color accuracy, and durability. May formulate the PVC material to enhance ink receptivity and ensure consistent printing results across various ink technologies.

By considering these factors and selecting a PVC backlit flex banner with the appropriate composition, users can achieve optimal light diffusion and print quality in their backlit displays.

English

English русский

русский Français

Français Español

Español