I. What is PVC Tensile Fabric?

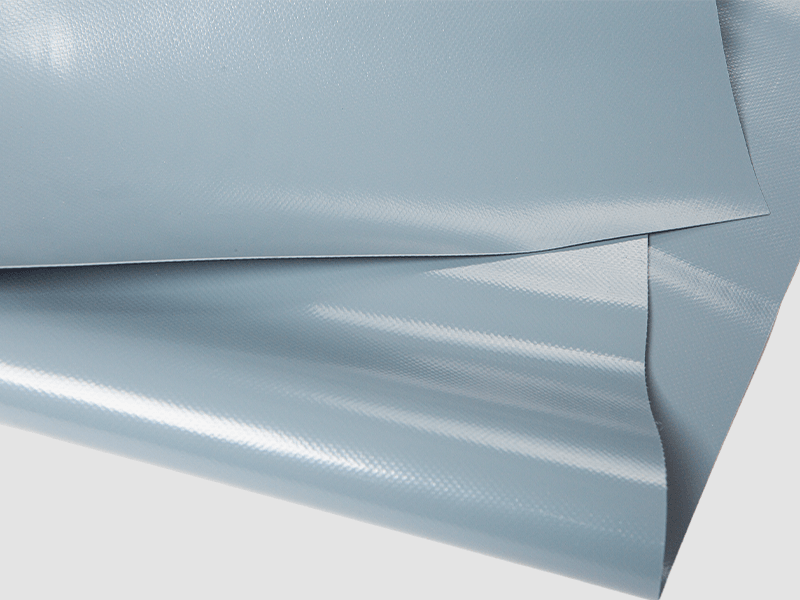

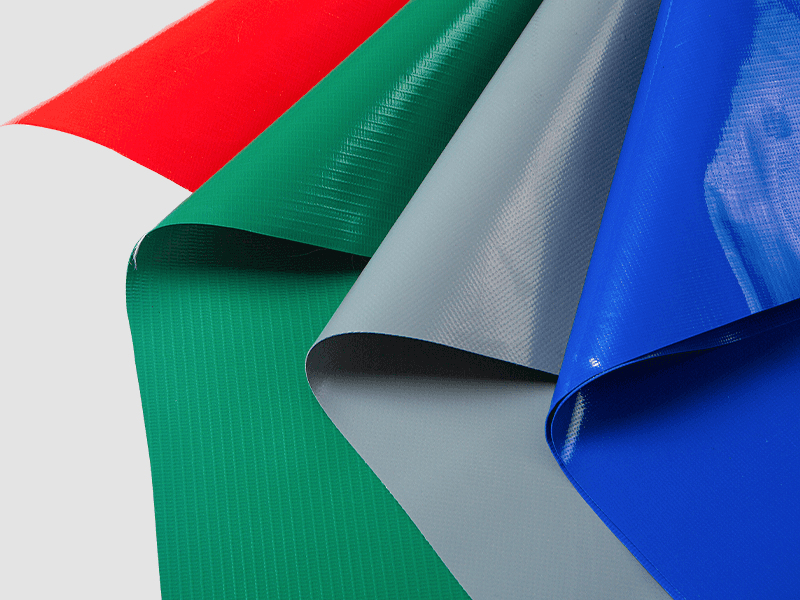

PVC Tensile Fabric (polyvinyl chloride tension fabric) is a high-performance material widely used in architectural membrane structures, awnings, temporary venues, advertising displays and other fields. It is usually made of high-strength polyester fiber or glass fiber as the base material, and one or more layers of polyvinyl chloride (PVC) material are coated on its surface. It has good waterproofness, weather resistance and certain light transmittance.

Due to its light weight and high strength, PVC tension fabric is increasingly favored in modern architectural design and industrial applications. Among them, tensile strength is one of the key indicators to measure its structural performance.

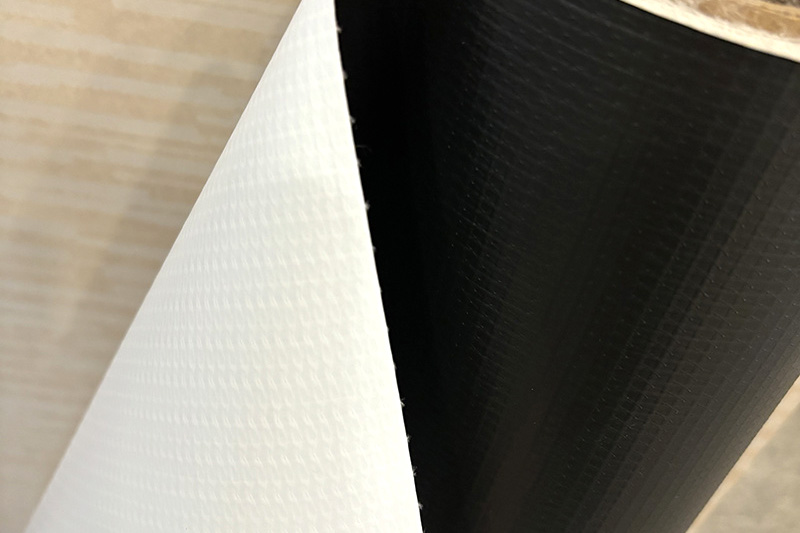

II. Structural composition and mechanical properties of PVC Tensile Fabric

The mechanical properties of PVC tension fabric mainly depend on its three-layer structure:

Base Fabric:

It is mostly woven with high-strength polyester fiber (Polyester) or glass fiber (Fiberglass).

These fibers have extremely high initial modulus and tensile strength, and are the core of the entire fabric.

Coating Layer:

The main component is PVC resin, which gives the fabric waterproof, UV protection, flame retardant and other functions.

Although PVC itself has good ductility, its tensile strength is not as good as that of the fiber substrate.

Surface treatment layer (Top Finish):

PVDF (polyvinylidene fluoride) or acrylic materials are often used for surface protection to improve durability and self-cleaning.

It has little effect on tensile strength, but helps to extend service life.

Therefore, the tensile strength of PVC Tensile Fabric mainly comes from the performance of its internal fiber substrate, while the PVC coating plays an auxiliary role in enhancing environmental adaptability.

III. Tensile Strength Performance of PVC Tensile Fabric

1. Tensile Strength Value Range

Depending on different product specifications and manufacturing processes, the tensile strength of PVC tension fabric is generally within the following range:

Warp (longitudinal): 1500~5000 N/5cm

Weft (transverse): 1000~4000 N/5cm

This strength level is much higher than ordinary canvas or tarpaulin materials, close to or even exceeding the specific strength (strength per unit weight) of some metal sheets.

Note: N/5cm means the Newton tensile force that can be borne per 5 cm width.

2. Comparison of tensile properties

Compared with common building materials:

| Ordinary canvas | 300~800 | Low cost, but poor strength |

| Polyester fabric | 1000~2000 | Medium strength, commonly used in tents |

| PVC Tensile Fabric | 1500~5000 | High strength, waterproof, strong plasticity |

| PTFE fiberglass membrane | 3000~6000 | Higher end, longer life, higher cost |

It can be seen that PVC tension fabrics are outstanding in terms of cost-effectiveness and are suitable for mid-to-high-end tensile membrane structure projects.

3. Anisotropic properties

PVC tension fabrics usually show obvious anisotropic characteristics, that is, the tensile strength in the warp (longitudinal) direction is higher than that in the weft (transverse) direction. This is due to the difference in the weaving direction of the fiber. Therefore, during design and construction, the force direction must be considered and the structural support must be arranged reasonably to avoid material tearing due to uneven force.

IV. Main factors affecting tensile strength

Base material type and density:

Using high-strength polyester fiber or glass fiber as the base material can significantly improve the tensile performance; the higher the fiber density, the stronger the tensile strength.

Coating thickness and formula:

PVC coating that is too thick may reduce the flexibility of the fabric, but has limited effect on the overall strength; additives such as plasticizers and stabilizers will affect the long-term strength retention rate.

Environmental aging factors:

Long-term exposure to ultraviolet rays, high temperature, and humidity will cause PVC aging and fiber fatigue, thereby reducing tensile strength. High-quality products will alleviate this problem by adding a UV protective layer.

Installation and maintenance methods:

Improper tensioning angles, connection methods or local stress concentration may also cause early damage, affecting the tensile performance in actual use.

V. Application scenarios and engineering practice verification

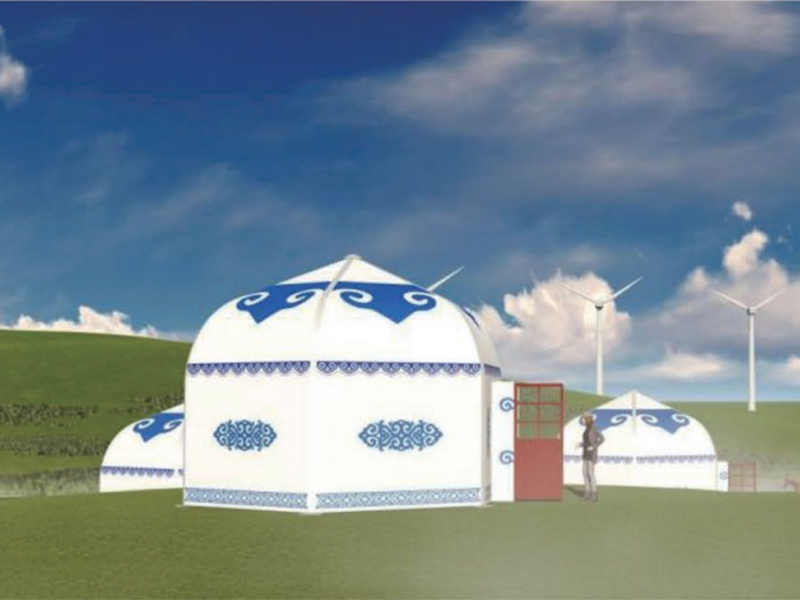

PVC tension fabric has been widely used in many fields due to its excellent tensile performance:

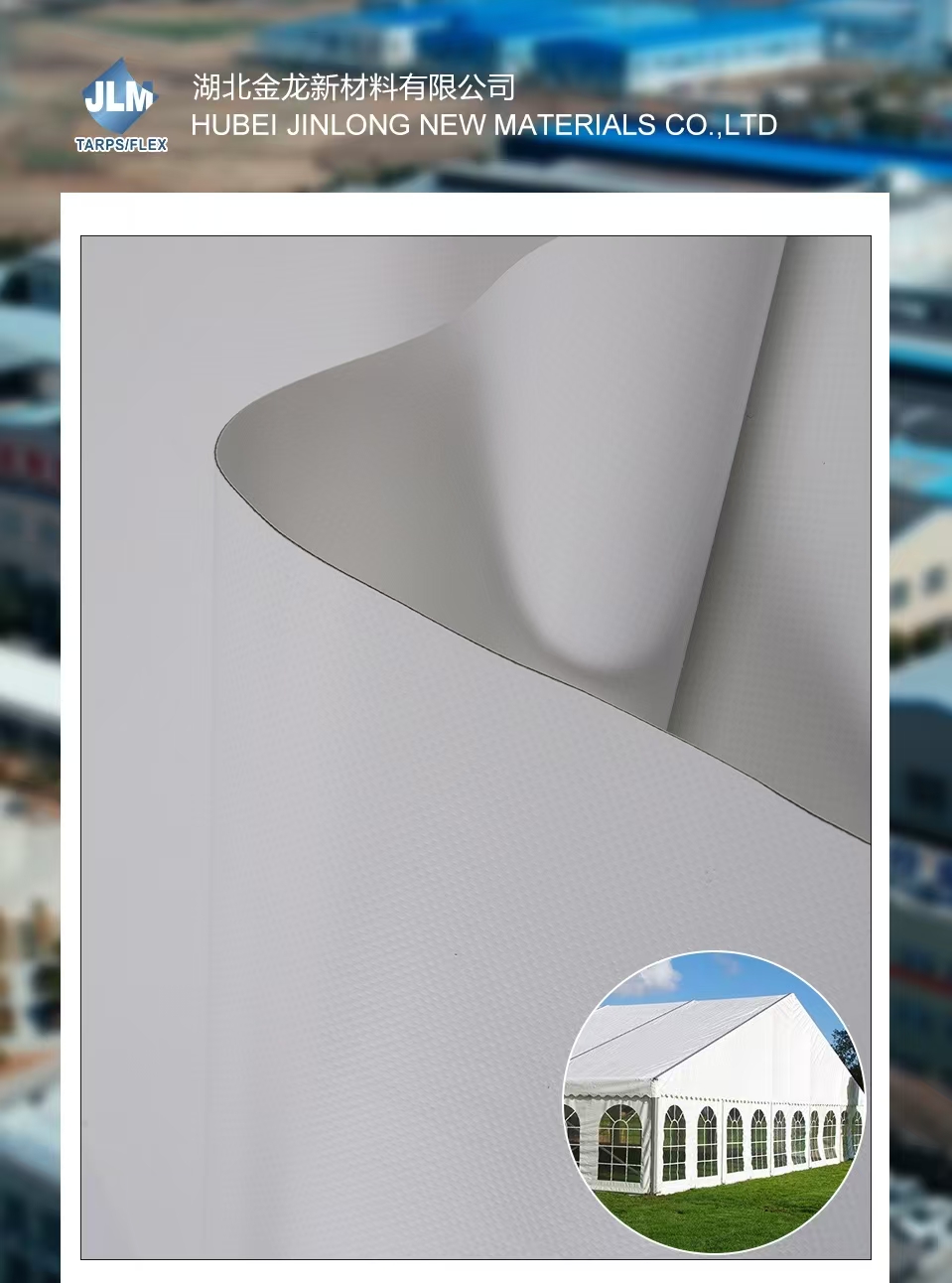

Sports venues and exhibition centers: such as the membrane structure around the Beijing National Stadium "Bird's Nest" and the Shanghai World Expo Axis;

Commercial plazas and parking sheds: using their large span and lightweight advantages to create open sheltered spaces;

Agricultural and industrial facilities: such as greenhouses, warehouse sheds, etc.;

Advertising and temporary event construction: quick installation and easy disassembly, suitable for exhibitions, performances and other scenes.

In these engineering practices, PVC tension fabrics have shown good structural stability and safety and reliability, further proving the actual value of its high tensile strength.

PVC Tensile Fabric does have a high tensile strength, especially for architectural structures and industrial uses that require lightweight, high strength and tensile molding. Its tensile performance not only meets the requirements of conventional loads, but also can resist external pressures such as wind loads and snow loads to a certain extent. However, in order to give full play to its performance advantages, it is also necessary to combine scientific design, reasonable installation and regular maintenance.

English

English русский

русский Français

Français Español

Español