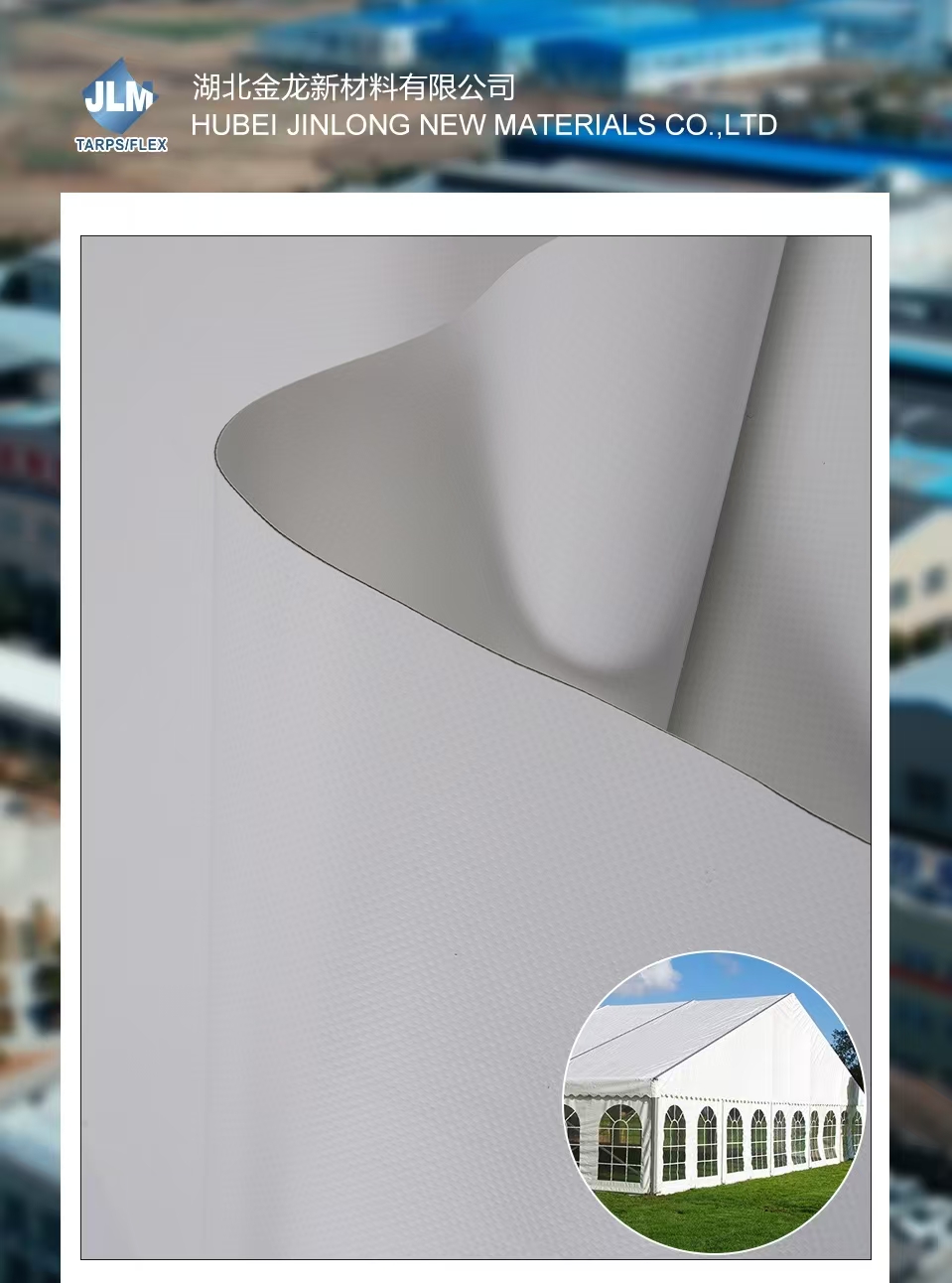

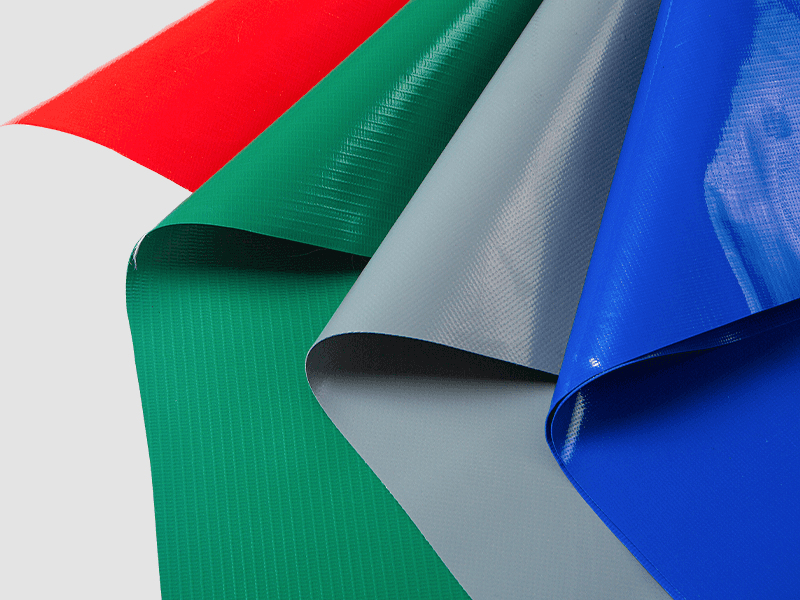

PVC Laminated Tarpaulin is a high-performance protective material widely used in construction sites, logistics and transportation, temporary storage, outdoor activities and other fields. One of its core advantages is its excellent waterproof performance, which can provide stable and reliable protection even in harsh outdoor environments such as heavy rain, strong winds and high humidity. So, how does PVC composite tarpaulin achieve effective waterproofing? This is closely related to its material structure, production process and functional coating.

1. Multi-layer composite structure: building a basic waterproof barrier

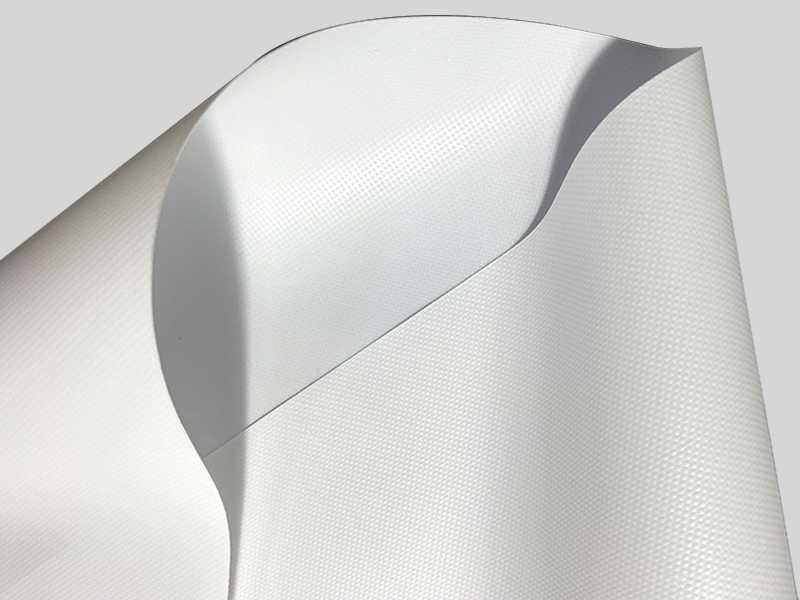

PVC composite tarpaulin usually consists of three layers:

Base material layer: generally high-strength polyester fiber (such as polyester mesh cloth), providing good tensile strength and tear resistance;

Middle adhesive layer: hot melt adhesive or other polymer adhesives are used to firmly bond the base material to the surface layer;

PVC surface layer: a dense PVC film layer is formed by high-temperature calendering or coating process, which is the core part of realizing the waterproof function.

This multi-layer composite structure not only enhances the overall strength, but also blocks the water penetration path through the PVC film layer, forming a "waterproof barrier" in a physical sense.

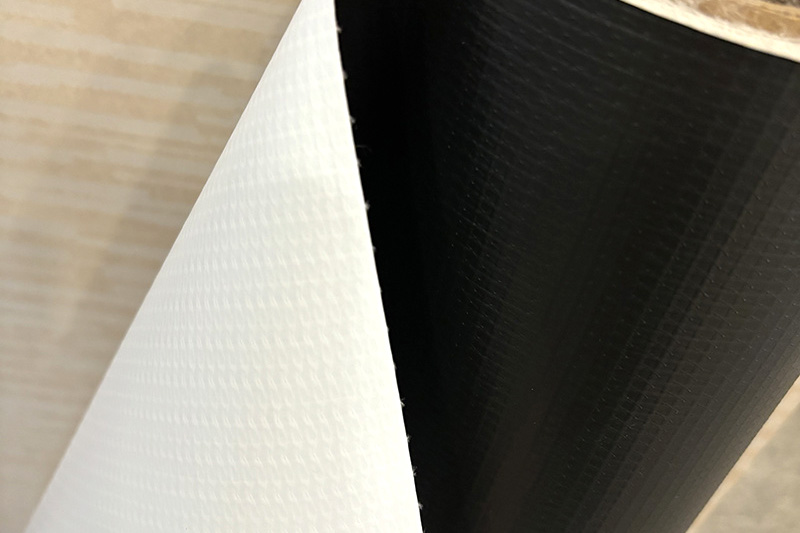

2. Excellent waterproofness of PVC material itself

Polyvinyl chloride (PVC) itself is a hydrophobic polymer material with extremely low water absorption (usually less than 0.5%). After foaming or densification treatment, the surface of PVC coating becomes smoother and denser, which can effectively prevent the penetration of rainwater, snow water and even high-pressure water flow. In addition, PVC material also has a certain flexibility, and it is not easy to produce cracks when deformed by external force, thus avoiding leakage caused by structural damage.

3. Seam treatment technology: prevent "blind spot of water leakage"

Even if the material itself has excellent waterproof performance, if the seam is not properly treated, it may still become a hidden danger of water leakage. Therefore, PVC composite tarpaulin usually adopts the following methods to enhance the sealing of seams during the manufacturing process:

High-frequency heat welding: Use high-frequency electromagnetic waves to make the PVC material partially melt and bond to form a seamless connection;

Waterproof tape edge sealing: Secondary sealing treatment of the seams to prevent pinhole water seepage;

Edge reinforcement: Improve the tear resistance and waterproof integrity of the edge area.

These technological means effectively improve the overall sealing performance of the tarpaulin, ensuring that it is still watertight under strong wind and rain conditions.

4. Additional functional coatings enhance protection capabilities

In order to further improve the waterproof effect and environmental adaptability, some functional coatings are often added to the surface of PVC composite tarpaulins, such as:

Anti-ultraviolet coating: reduce material aging caused by sunlight exposure and extend service life;

Anti-mildew and antibacterial coating: prevent mold growth in humid environments and keep the material clean;

Flame retardant coating: improve fire resistance and meet specific industry safety standards.

These additional functions not only enhance the durability of waterproof performance, but also make the tarpaulin suitable for a wider range of complex outdoor environments.

The reason why PVC composite tarpaulins can achieve effective waterproofing in harsh outdoor environments is due to its scientific multi-layer composite structure, the hydrophobic properties of PVC materials themselves, advanced seam sealing technology and functional coatings. With the continuous advancement of material technology, future PVC composite tarpaulins will continue to upgrade in terms of environmental protection, recyclability, and intelligence, providing more comprehensive and efficient solutions for outdoor protection.

English

English русский

русский Français

Français Español

Español