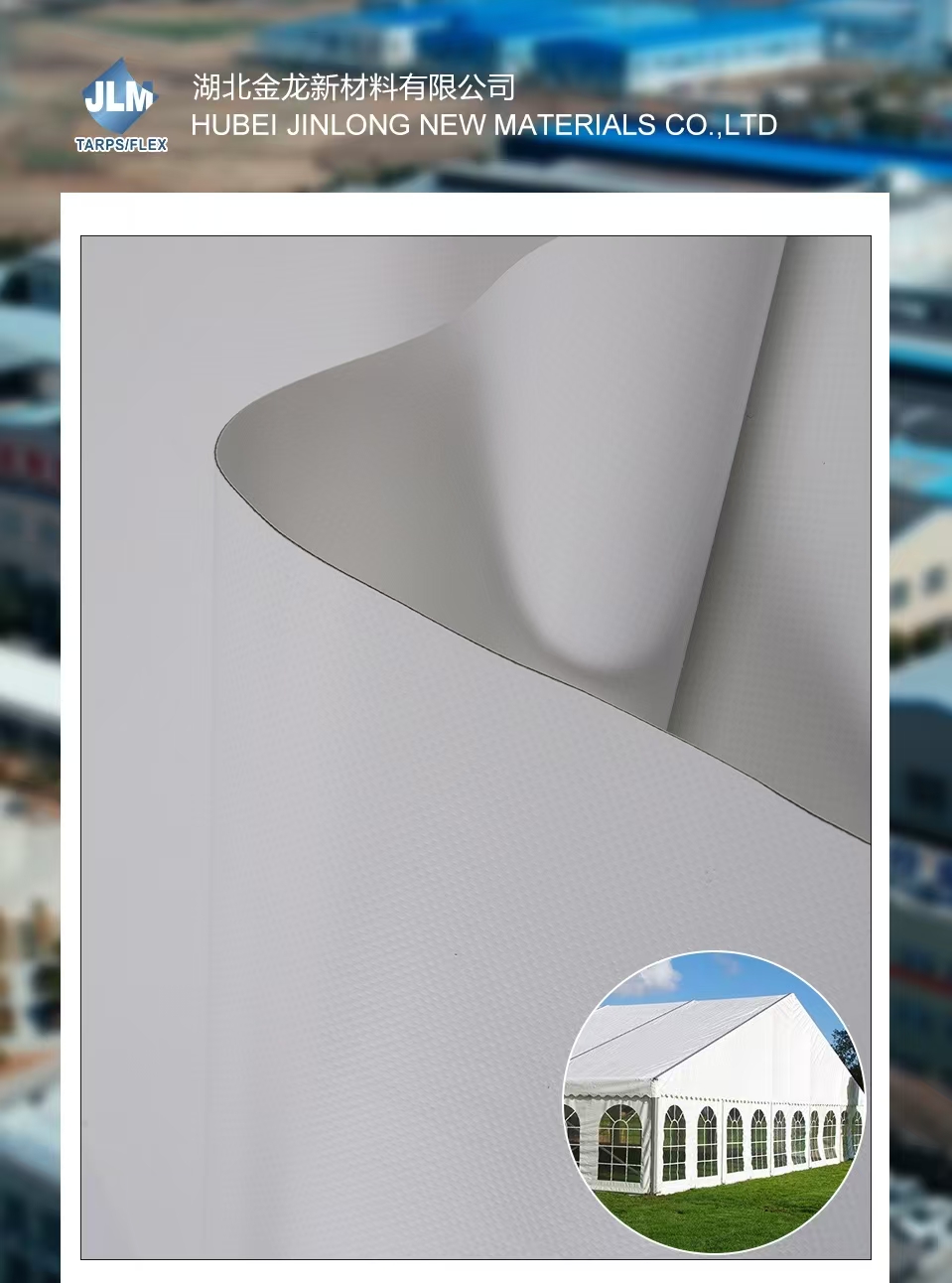

PVC tensile tent fabrics have become a popular choice for outdoor structures, event tents, architectural canopies, and temporary shelters. These fabrics combine the flexibility of PVC coatings with the strength of woven polyester or other reinforcement materials, resulting in a material that is both durable and visually appealing. One key consideration for these fabrics is how they perform under different climatic conditions, as weather exposure can significantly impact durability, safety, and aesthetic longevity.

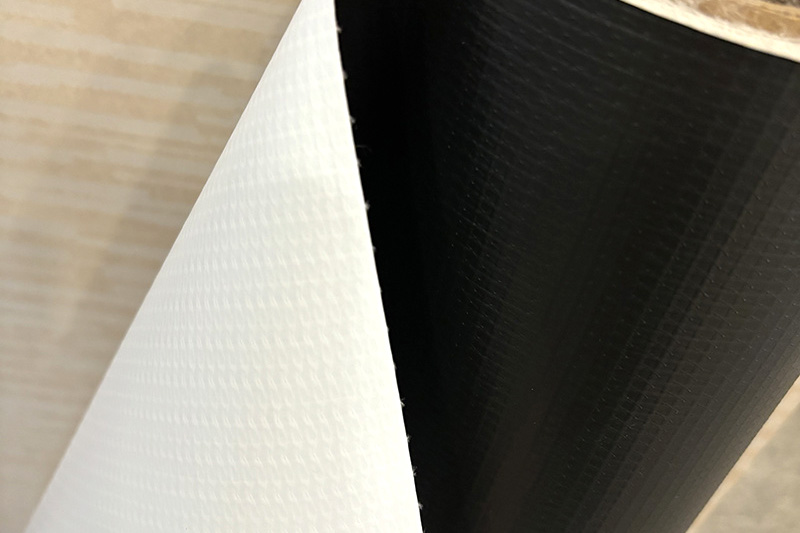

1. Composition and Structure of PVC Tensile Tent Fabric

PVC tensile fabrics typically consist of a woven polyester core coated with polyvinyl chloride (PVC). This combination provides:

- Tensile strength for large spans and dynamic loads.

- Waterproofing to protect against rain and moisture.

- UV resistance to minimize degradation from sunlight.

- Flexibility for creating complex architectural forms.

The coating and weaving density directly influence the fabric’s performance in various climates, determining its resistance to wind, temperature fluctuations, humidity, and solar exposure.

2. Performance in Hot and Sunny Climates

In hot and sunny climates, UV radiation and high temperatures are the primary challenges for outdoor fabrics:

-

UV Resistance

High-quality PVC tensile fabrics are treated with UV stabilizers to resist color fading, material embrittlement, and surface cracking. Without UV protection, prolonged sun exposure can degrade the PVC layer, reducing tensile strength and visual appeal. -

Heat Resistance

PVC tensile fabrics can typically withstand temperatures up to 70–80°C without significant deformation. In extremely hot conditions, the fabric maintains dimensional stability, ensuring that tensile structures retain their shape and load-bearing capacity. -

Reflection and Coating Options

Some PVC fabrics feature reflective coatings or light-colored surfaces to minimize heat absorption, reducing internal temperatures in event tents or canopies and increasing occupant comfort.

3. Performance in Cold and Freezing Climates

Cold climates present different challenges, including low temperatures, frost, and snow loads:

-

Flexibility at Low Temperatures

PVC tensile fabrics retain excellent flexibility even in sub-zero temperatures, preventing cracking or brittleness. This ensures that tents or canopies can withstand folding, tension adjustments, and snow load stress. -

Resistance to Ice and Frost

The smooth PVC surface prevents ice adhesion and facilitates snow or frost removal. Properly tensioned fabrics distribute snow weight evenly, reducing the risk of tearing or sagging. -

Thermal Insulation

While PVC itself is not highly insulating, reflective and multi-layered tensile fabrics can provide moderate thermal protection, which is useful for temporary shelters in cold regions.

4. Performance in Humid and Rainy Climates

Humidity and rainfall test the waterproofing and mold resistance of PVC tensile fabrics:

-

Waterproofing

The PVC coating provides a complete barrier against rain, ensuring that water does not penetrate the structure. Well-sealed seams and proper installation further enhance waterproof performance. -

Mold and Mildew Resistance

PVC is inherently resistant to moisture absorption, which prevents the growth of mold and mildew common in humid environments. This maintains hygiene, appearance, and structural integrity over time. -

Corrosion and Cleaning

Unlike natural fabrics, PVC does not corrode or weaken in wet conditions. The smooth surface allows for easy cleaning and maintenance, which is particularly valuable in tropical or coastal areas.

5. Performance in Windy and Stormy Conditions

Wind and storms test the tensile strength and anchoring capability of PVC fabrics:

-

Tensile Strength

PVC tensile fabrics are designed to withstand dynamic wind loads by distributing stress across the woven structure. High-strength polyester cores ensure that the fabric does not tear or deform under strong gusts. -

Flexibility and Elasticity

The inherent elasticity of PVC fabrics allows them to absorb sudden wind impacts, preventing catastrophic failures that can occur with rigid materials. -

Structural Integration

When combined with properly engineered support frames, PVC tensile fabrics maintain shape, tension, and safety even in adverse weather conditions.

6. Maintenance Considerations Across Climates

To ensure optimal performance across climates:

- Regular Inspection: Check for UV degradation, tears, or seam wear, especially in hot or windy regions.

- Cleaning: Remove dirt, debris, or salt deposits to prevent long-term surface damage.

- Proper Tensioning: Maintain even tension to prevent sagging under snow or water accumulation.

- Protective Coatings: Apply reflective or anti-UV treatments in sunny climates and consider reinforcement in high-wind areas.

Conclusion

PVC tensile tent fabrics perform well in diverse climatic conditions due to their combination of strength, flexibility, waterproofing, and UV resistance. They withstand hot, cold, humid, and windy environments, making them suitable for a wide range of applications from event tents and outdoor canopies to architectural structures. Proper selection of material grade, coating, and installation techniques ensures that PVC tensile fabrics provide long-lasting durability, aesthetic appeal, and reliable protection across all weather conditions.

English

English русский

русский Français

Français Español

Español