Introduction to PVC Flex Banners

1.1 What is PVC Flex Banner? Definition and Basic Properties

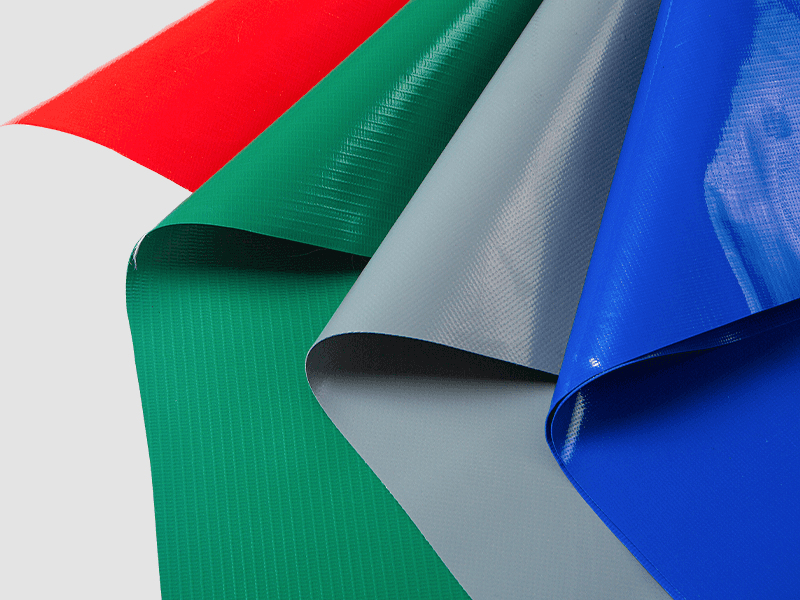

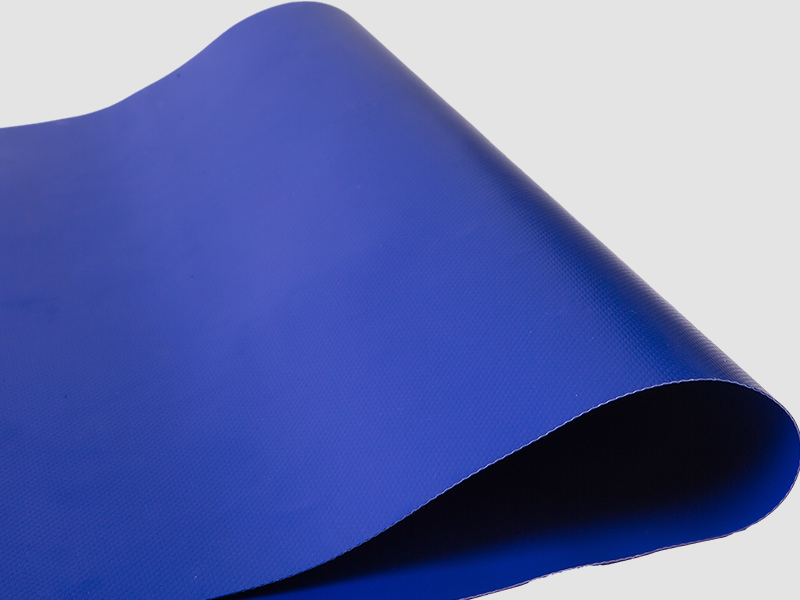

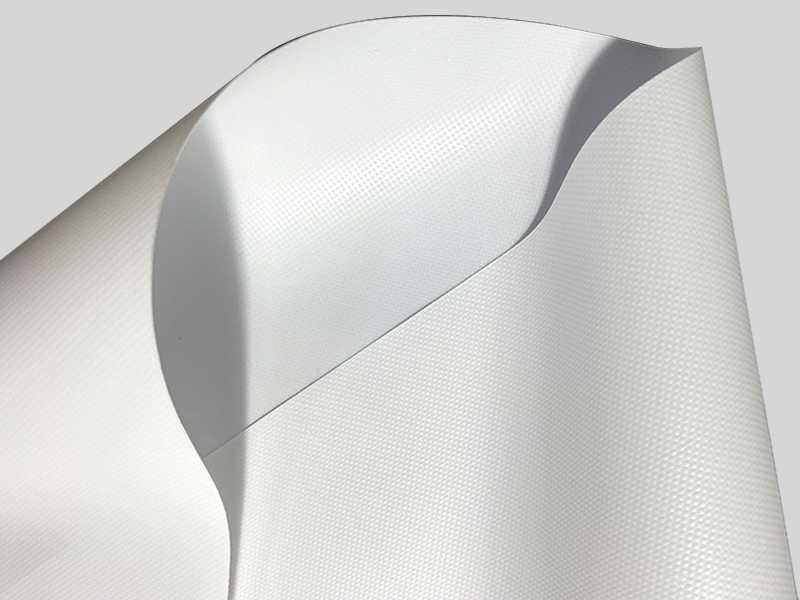

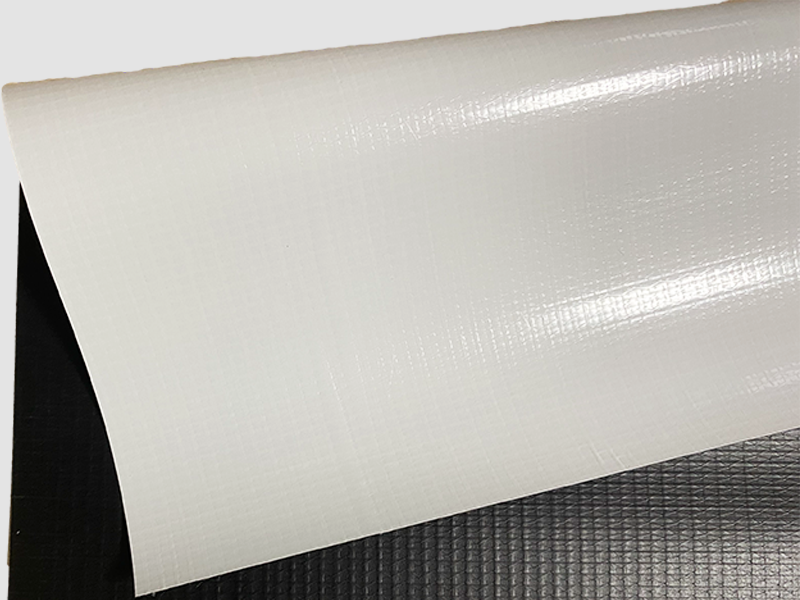

A PVC flex banner is a widely used advertising medium made from polyvinyl chloride (PVC), a durable and flexible synthetic material. Often referred to simply as a “flex banner,” it is designed to withstand harsh environmental conditions while providing a high-quality printing surface. Its composition typically includes a PVC layer laminated with a polyester or fabric mesh core, which ensures strength, flexibility, and resistance to tearing. This combination of materials makes PVC flex banners ideal for large-format printing applications, where clarity, vibrancy, and longevity are essential.

The material is highly versatile, capable of supporting a range of printing techniques, including solvent printing, eco-solvent printing, UV printing, and latex printing. This flexibility allows businesses to produce banners with vivid graphics, sharp text, and rich color contrasts, ensuring messages stand out in both indoor and outdoor advertising contexts. PVC flex banners can be manufactured with various surface finishes such as glossy or matte, and with different light transmission properties, such as frontlit, backlit, or blockout, providing tailored solutions for specific display needs.

Some key properties of PVC flex banners include:

Durability: Resistant to tearing, UV radiation, and extreme weather conditions.

Waterproof: Suitable for outdoor use in rain, snow, or humidity.

Flexible: Easy to roll, transport, and install on various surfaces.

Printable: Compatible with multiple printing technologies for vibrant and long-lasting visuals.

Cost-Effective: Offers a high return on investment compared to traditional banner materials.

These properties make PVC flex banners a go-to choice for businesses, marketers, event organizers, and construction projects seeking a reliable and visually impactful advertising solution.

1.2 History and Evolution

The use of banners as an advertising medium dates back centuries, with early materials including cloth, canvas, and paper, which were printed or hand-painted to convey messages. While traditional materials were functional, they lacked durability and required frequent replacement, especially in outdoor environments.

With the rise of synthetic materials in the mid-20th century, PVC emerged as a practical alternative. PVC’s lightweight yet strong properties allowed for the production of larger banners that could endure exposure to sunlight, wind, and rain. Over time, technological advancements in printing and lamination further enhanced the appeal of PVC flex banners. Modern manufacturing processes introduced reinforced edges, grommets, and seamless welding, enabling large-format applications such as billboards, building wraps, and stadium signage.

Today, PVC flex banners represent the convergence of durability, flexibility, and print quality, making them a staple in both commercial advertising and event signage. Their evolution from traditional cloth banners to high-tech, digitally printable materials illustrates the ongoing drive for innovation in marketing media.

1.3 Advantages of Using PVC Flex Banners

PVC flex banners offer several advantages over other traditional and modern advertising materials. Understanding these benefits can help businesses make informed decisions about their promotional strategies.

1. Durability and Weather Resistance

One of the most significant advantages of PVC flex banners is their long-lasting durability. Unlike paper or cloth banners that deteriorate quickly under sunlight or rain, PVC banners are designed to resist UV fading, water, and wind damage. This property makes them ideal for outdoor advertising, including billboards, street banners, and building wraps, where exposure to environmental factors is unavoidable.

2. Cost-Effectiveness

While other high-quality materials like vinyl or fabric may offer similar print quality, PVC flex banners are generally more affordable, particularly when considering their longevity. Their durability reduces the need for frequent replacement, lowering long-term marketing costs. Additionally, their compatibility with multiple printing methods allows for bulk production without excessive expenses.

3. Versatility in Printing and Applications

PVC flex banners are compatible with solvent, eco-solvent, UV, latex, and screen printing, giving marketers the flexibility to choose the most suitable technique based on image quality, environmental considerations, and budget. Their versatility extends to applications as well, ranging from outdoor advertising, trade shows, and retail signage to event banners, construction safety signage, and vehicle wraps.

4. Customization Options

These banners can be customized in terms of size, thickness, surface finish, and light transmission, allowing businesses to create highly specific solutions for their marketing campaigns. Whether a client requires a glossy finish for a high-impact visual display or a blockout banner for double-sided visibility, PVC flex banners provide options that cater to every need.

5. Ease of Installation and Maintenance

PVC flex banners are lightweight, flexible, and easy to transport, making installation straightforward. They can be hung, mounted, or attached to banner stands without specialized equipment. Maintenance is also simple: banners can be cleaned with mild detergents, and minor tears can be repaired quickly, ensuring continued usability and professional appearance.

6. Sustainability Considerations

While PVC production has environmental impacts, many manufacturers are now exploring recycling programs and eco-friendly printing methods, such as eco-solvent and latex printing, to reduce the ecological footprint. This shift aligns PVC flex banners with growing trends in sustainable advertising, making them a responsible choice for environmentally conscious organizations.

In conclusion, PVC flex banners combine durability, affordability, and versatility, making them an essential tool for modern advertising. From their historical evolution to their contemporary applications, these banners offer unmatched flexibility in design and printing, while withstanding the rigors of outdoor environments. Whether for a massive billboard, a trade show display, or a promotional event, PVC flex banners remain a reliable and impactful medium for conveying messages and capturing audience attention.

Types of PVC Flex Banners

PVC flex banners are not a one-size-fits-all solution. They come in various types, each designed to meet specific advertising, environmental, and aesthetic requirements. Understanding the differences in surface finish, light transmission, weave density, and specialty features is essential for selecting the right banner for a particular application.

2.1 Based on Surface Finish

The surface finish of a PVC flex banner significantly affects visual appeal and print quality. The two most common finishes are glossy and matte.

Glossy PVC Flex Banner

Glossy PVC banners have a shiny, reflective surface that enhances colors and creates a vibrant, eye-catching effect. They are ideal for:

High-impact outdoor advertisements, such as billboards and building wraps.

Indoor promotional displays where vivid color reproduction is critical.

Applications requiring attention-grabbing visuals, like product launches or event signage.

The glossy finish amplifies contrast and saturation, making printed graphics appear sharper and more visually appealing. However, it may reflect sunlight in outdoor settings, which should be considered in placement.

Matte PVC Flex Banner

Matte banners feature a non-reflective surface, providing a smooth, glare-free appearance. They are suitable for:

Indoor environments with controlled lighting, such as trade shows and retail stores.

Situations where text readability is more important than color intensity.

Professional settings where a subtle, sophisticated look is desired.

Matte banners reduce reflection issues and are often preferred when placing banners in brightly lit areas.

2.2 Based on Light Transmission

PVC flex banners can also be classified by how they interact with light, which directly influences their application.

Frontlit PVC Flex Banner

Frontlit banners are designed to be illuminated from the front, making them ideal for:

Street advertising and highway billboards.

Building facades and commercial outdoor signage.

Advantages include high visibility during the day, excellent color vibrancy, and cost-effectiveness, as they do not require backlighting systems.

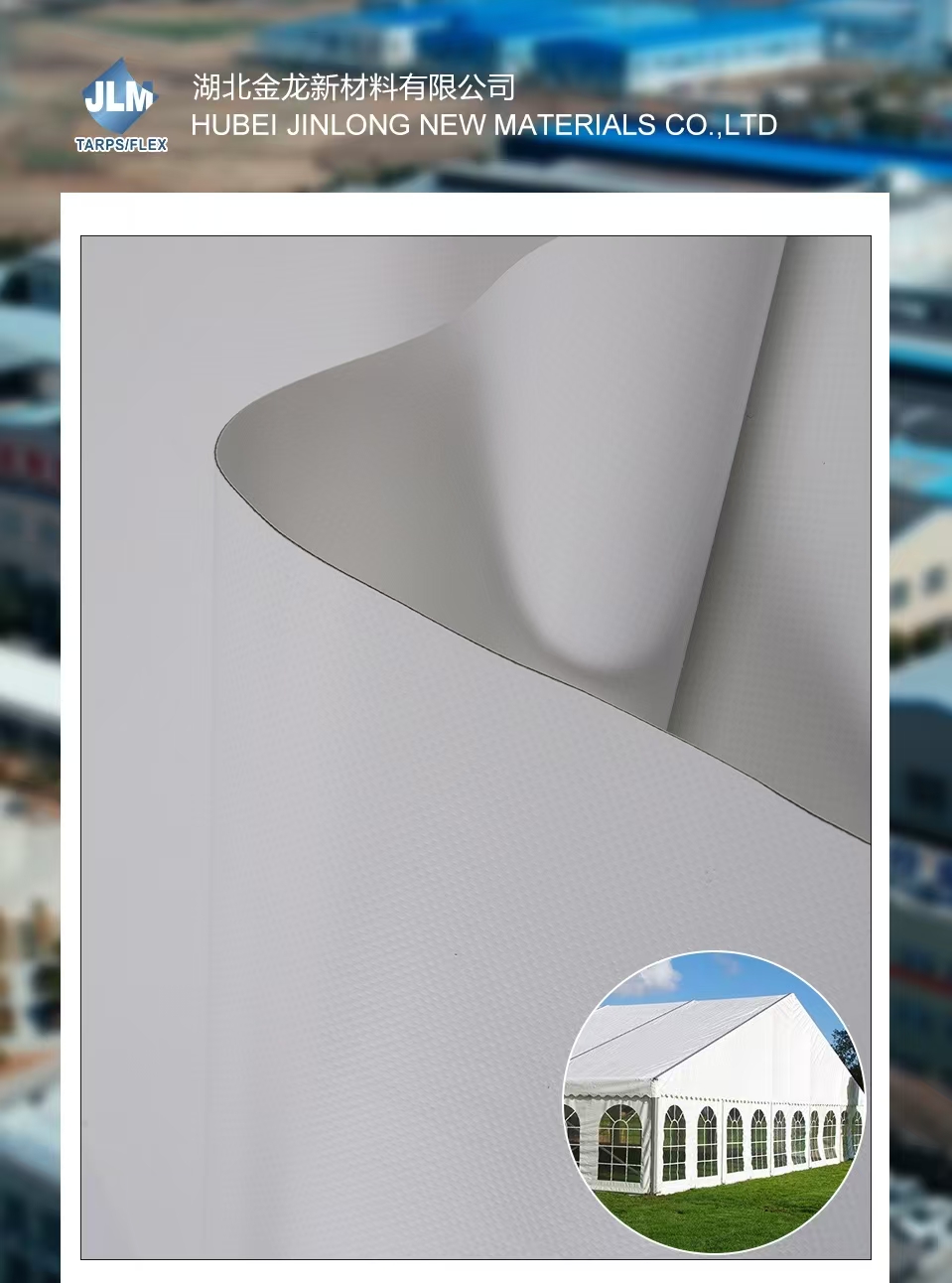

Backlit PVC Flex Banner

Backlit banners are specifically manufactured to allow light to pass through the material, making them perfect for lightbox displays and illuminated signage. Benefits include:

Even light diffusion, enhancing image clarity and color intensity.

Effective use in nighttime advertising, ensuring visibility after dark.

Applications in indoor retail stores and transport hubs, where illumination attracts attention.

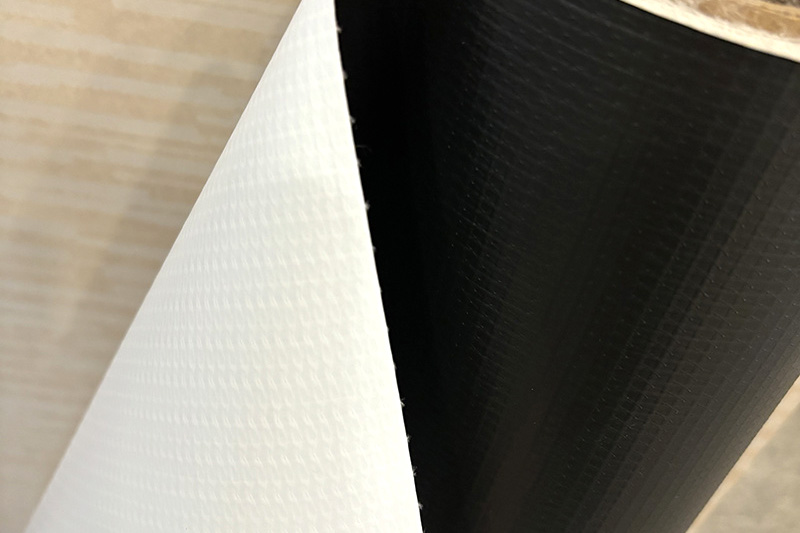

Blockout PVC Flex Banner

Blockout banners have a double-layered design that prevents light from passing through. They are used for:

Double-sided displays, where content is visible on both sides without interference.

High-contrast outdoor signage, preventing sunlight from showing through and washing out colors.

Event or stage banners, where solid, opaque visuals are required.

2.3 Based on Weave Density

The weave density of the polyester mesh core affects strength, flexibility, and print sharpness.

Low-density weave: Lighter and more flexible, ideal for short-term indoor displays.

Medium-density weave: Balanced strength and print quality, suitable for general outdoor advertising.

High-density weave: Maximum durability and tear resistance, preferred for large-scale outdoor banners exposed to wind or harsh weather.

Choosing the correct weave density ensures the banner withstands environmental stress while maintaining a professional appearance.

2.4 Specialty PVC Flex Banners

Beyond standard options, several specialty PVC banners cater to unique needs.

Reflective PVC Flex Banner

Reflective banners include special coatings that bounce light back toward the source, enhancing visibility in low-light or night conditions. Common uses include:

Safety signage on construction sites or roads.

Promotional displays in poorly lit areas.

Double-Sided Printable PVC Flex Banner

Double-sided banners allow different content on each side, maximizing exposure in pedestrian areas, trade shows, or suspended outdoor placements. Features include:

Blockout layer to prevent bleed-through.

High-quality print compatibility with solvent, UV, or eco-solvent methods.

These specialty banners expand the versatility of PVC flex materials, accommodating unique marketing strategies and environmental conditions.

Summary

Understanding the types of PVC flex banners is critical for making the right choice for advertising and promotional campaigns. Surface finish, light transmission, weave density, and specialty features all impact durability, visual appeal, and printing outcomes. Whether opting for a glossy frontlit banner for a billboard, a matte indoor trade show banner, or a double-sided reflective safety banner, selecting the appropriate type ensures maximum effectiveness and ROI.

With this foundation, the next step is to explore printing techniques, which determine how vibrant, durable, and impactful your PVC flex banner will be in real-world applications.

Printing Techniques for PVC Flex Banners

The printing technique chosen for a PVC flex banner significantly influences its visual impact, durability, and suitability for different environments. Various methods are available, each offering distinct advantages, applications, and cost considerations. Understanding these techniques helps marketers, designers, and signage professionals select the most effective solution for their needs.

3.1 Solvent Printing

Solvent printing is one of the most widely used methods for PVC flex banners. It involves the use of solvent-based inks that penetrate the surface of the banner material, creating vivid, durable, and weather-resistant images.

Advantages:

High durability: Resistant to fading, scratching, and outdoor weather conditions.

Large-format capability: Ideal for billboards, building wraps, and street banners.

Cost-effectiveness: Suitable for bulk production of outdoor signage.

Suitable Applications:

Outdoor advertising campaigns exposed to sunlight, wind, and rain.

Long-term displays requiring vibrant color retention.

Large banners where print longevity outweighs environmental concerns.

Solvent printing is especially favored for frontlit and blockout banners, providing high-quality output that stands out in urban environments.

3.2 Eco-Solvent Printing

Eco-solvent printing uses low-VOC inks, making it a more environmentally friendly alternative to traditional solvent printing. While maintaining similar quality, eco-solvent inks are less toxic and safer for indoor use.

Advantages:

Environmentally responsible: Reduced emissions and chemical impact.

Good durability: Suitable for both indoor and short- to medium-term outdoor applications.

Fine detail reproduction: Capable of sharp graphics and photo-quality prints.

Suitable Applications:

Indoor signage such as trade shows, retail displays, and office branding.

Medium-term outdoor campaigns with moderate exposure to weather.

Eco-conscious brands seeking sustainable advertising solutions.

Eco-solvent printing is often paired with matte and glossy PVC flex banners, offering flexibility for different design aesthetics.

3.3 UV Printing

UV printing is a modern digital technique that uses ultraviolet light to cure inks directly onto the PVC surface. This results in highly durable, vibrant, and scratch-resistant banners.

Advantages:

Exceptional color vibrancy: Produces sharp, high-definition graphics.

Long-lasting durability: Resistant to UV fading, water, and abrasion.

Eco-friendly: Minimal solvent emissions compared to traditional solvent printing.

Suitable Applications:

Outdoor billboards, street banners, and building wraps requiring high-impact visuals.

Event banners exposed to sunlight for extended periods.

Any installation demanding crisp, detailed graphics with long-term reliability.

UV printing is particularly effective on glossy and backlit banners, where color intensity and light diffusion are critical.

3.4 Latex Printing

Latex printing uses water-based inks that are both eco-friendly and highly versatile. This method combines the benefits of solvent durability and UV vibrancy while being safer for indoor environments.

Advantages:

Eco-friendly: Non-toxic, low-VOC inks suitable for indoor use.

High quality: Sharp, detailed, and vibrant prints.

Flexible: Compatible with a wide range of PVC flex banner types.

Suitable Applications:

Indoor advertising, including retail signage, trade show banners, and point-of-sale displays.

Outdoor campaigns where eco-conscious practices are important.

High-resolution graphics requiring smooth gradients and photo-quality images.

Latex printing has become increasingly popular due to its combination of durability, quality, and sustainability, making it a go-to choice for modern marketing campaigns.

3.5 Screen Printing

Screen printing is a traditional method that uses stencils and a mesh screen to apply ink to the banner. While less common in modern digital production, it is still used for specific applications requiring solid, vibrant colors.

Advantages:

High opacity: Colors appear rich and vivid, especially on reflective or blockout banners.

Durable: Inks bond well with the PVC surface.

Cost-effective for bulk runs: Ideal for large orders with limited color requirements.

Suitable Applications:

Promotional banners for events, sports, and concerts.

Industrial or safety signage requiring bold, single-color designs.

Large-scale banners with repetitive patterns or logos.

Screen printing remains relevant for projects where durability and color intensity take priority over detailed photographic reproduction.

Summary

Choosing the right printing technique for a PVC flex banner depends on intended use, budget, environmental considerations, and desired visual effect.

| Printing Technique | Strengths | Ideal Applications |

| Solvent Printing | Durability, outdoor longevity | Billboards, building wraps |

| Eco-Solvent Printing | Eco-friendly, good detail | Indoor banners, moderate outdoor use |

| UV Printing | Vivid colors, high definition | Outdoor signage, backlit displays |

| Latex Printing | Eco-friendly, versatile | Indoor and outdoor, high-resolution graphics |

| Screen Printing | Bold colors, cost-effective | Event banners, industrial signage |

By understanding the capabilities of each technique, marketers can match the printing method to the PVC flex banner type, ensuring maximum impact and durability. Combining the right banner type with the proper printing method is crucial for achieving professional, eye-catching, and long-lasting advertising solutions.

Applications of PVC Flex Banners

PVC flex banners are among the most versatile advertising and signage solutions available. Their durability, print quality, and adaptability make them suitable for a wide range of applications, from outdoor billboards to indoor displays, events, and vehicle wraps. Understanding the practical applications helps businesses choose the right type of banner, printing method, and installation technique to maximize visibility and impact.

4.1 Outdoor Advertising

Outdoor advertising remains one of the most popular uses of PVC flex banners due to their weather resistance and large-format capability. Common applications include:

Billboards: Large-scale PVC banners are perfect for highways, urban centers, and commercial areas. Using frontlit or backlit banners ensures visibility day and night.

Building Wraps: PVC flex banners can cover entire building facades, transforming structures into dynamic advertising canvases. High-density weave and UV printing are often used for durability and high-impact visuals.

Street Banners: Hung between poles or along streets, PVC banners promote sales, festivals, or public events. Lightweight and tear-resistant options are preferred for windy conditions.

These applications leverage the vivid print quality, flexibility, and resilience of PVC banners, making them a cost-effective solution for long-term campaigns.

4.2 Indoor Advertising

PVC flex banners are equally effective indoors, providing professional, attention-grabbing signage without damaging interiors. Common indoor uses include:

Trade Show Displays: Banners serve as backdrops, booth signage, and promotional walls. Matte or glossy finishes can be chosen based on lighting conditions.

Retail Signage: PVC banners highlight promotions, new product launches, and seasonal campaigns. Double-sided printable banners can optimize floor space.

Point-of-Sale Advertising: Small to medium-sized banners attract customer attention near checkout areas or product displays. Eco-solvent or latex printing ensures safe indoor air quality.

Indoor banners benefit from high-resolution printing techniques and flexibility in size, making them ideal for temporary campaigns or long-term branding.

4.3 Event Signage

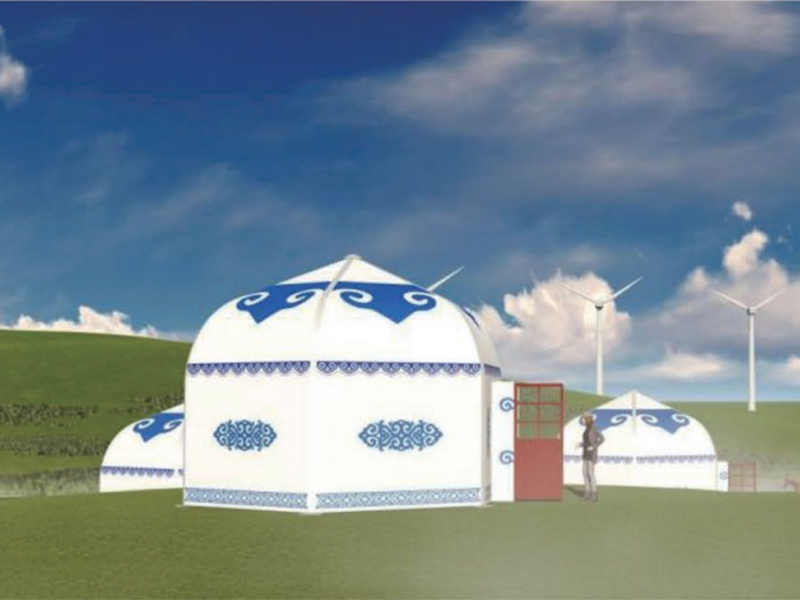

PVC flex banners are widely used for concerts, festivals, sports events, and conferences, providing both functional and promotional purposes.

Concerts and Festivals: Banners can display event names, sponsors, or schedules, and withstand outdoor exposure. Backlit or reflective banners enhance nighttime visibility.

Sports Events: Stadiums and arenas use PVC banners for team branding, sponsor advertisements, and directional signage. High-density, tear-resistant materials endure crowd and weather stress.

Corporate Events and Conferences: Trade shows, seminars, and product launches utilize banners for branding, navigation, and informational purposes. Double-sided or blockout banners ensure maximum visibility in high-traffic areas.

Event signage highlights the versatility and durability of PVC flex banners while delivering clear messaging and vibrant visuals.

4.4 Vehicle Wraps

PVC flex banners can be used for full or partial vehicle wraps, turning cars, vans, and buses into mobile advertising platforms.

Full Wraps: Cover the entire vehicle surface for maximum brand exposure.

Partial Wraps: Target specific areas like doors, hoods, or rear windows for cost-effective campaigns.

Vehicle wraps benefit from solvent or UV printing, which adheres to the flexible PVC surface and resists outdoor wear, UV rays, and water. This application transforms everyday vehicles into moving billboards, reaching a broad audience efficiently.

4.5 Construction and Safety Signage

The construction industry frequently uses PVC flex banners for safety notices, project branding, and site instructions.

Construction Site Signage: Displays warnings, rules, and safety guidelines clearly for workers and visitors. Reflective banners enhance visibility during low-light conditions.

Project Branding: Companies can use banners to showcase project details, sponsors, or promotional messages on scaffolding or fencing.

Directional and Informational Signage: PVC flex banners provide durable, weather-resistant instructions, guiding staff and visitors effectively.

These applications highlight PVC’s toughness, resistance to environmental factors, and versatility, making it ideal for high-traffic, high-stress areas.

Summary

PVC flex banners are highly adaptable advertising tools suitable for:

Outdoor Advertising: Billboards, building wraps, street banners.

Indoor Advertising: Trade shows, retail signage, point-of-sale displays.

Events: Concerts, sports events, corporate conferences.

Vehicle Wraps: Full or partial wraps for mobile marketing.

Construction and Safety Signage: Long-lasting, visible, and reflective displays.

The combination of material durability, versatile printing techniques, and customizable formats ensures that PVC flex banners deliver maximum visual impact across diverse environments. Proper selection of banner type, surface finish, and printing method enhances effectiveness, whether the goal is brand promotion, event information, or safety communication.

How to Choose the Right PVC Flex Banner

Selecting the right PVC flex banner is crucial for ensuring optimal visual impact, durability, and cost-effectiveness. With so many options in material type, surface finish, printing techniques, and environmental suitability, understanding the key factors can help businesses and marketers make informed decisions.

5.1 Factors to Consider

When choosing a PVC flex banner, it is essential to evaluate intended use, size, printing requirements, and environmental conditions:

Intended Use (Indoor vs. Outdoor)

Outdoor Applications: Require banners with high UV resistance, tear strength, and weatherproofing. Frontlit or backlit options are ideal for street banners, billboards, and building wraps.

Indoor Applications: Focus on aesthetic finish, high-resolution print, and safe ink choices. Eco-solvent or latex printing is preferred to maintain indoor air quality.

Size and Dimensions

Large banners need high-density weave PVC for strength and resistance to wind stress.

Smaller banners can use medium or low-density PVC, which is more flexible and cost-effective.

Printing Requirements

Consider image resolution, color fidelity, and finishing needs.

For high-impact visual campaigns, choose printing techniques like UV or latex printing.

Simpler text-based banners may be suitable for solvent or screen printing.

Environmental Conditions

Outdoor banners must withstand sunlight, rain, wind, and temperature fluctuations.

Special applications may require reflective or blockout banners for night visibility or double-sided displays.

5.2 Understanding Specifications

Key specifications affect performance, durability, and appearance:

Weight and Thickness: Heavier, thicker banners are more durable and suited for long-term outdoor use. Lightweight banners are easier to transport and install for short-term campaigns.

Tensile Strength: Determines how well a banner resists stretching or tearing, critical for large or suspended installations.

Tear Resistance: High tear resistance prevents damage during transportation, installation, or exposure to wind.

Light Transmission: Frontlit, backlit, and blockout options influence visibility, color vibrancy, and double-sided print capability.

Understanding these specifications ensures the banner meets practical requirements while maintaining high visual quality.

5.3 Choosing the Right Printing Technique

Selecting a compatible printing method is key to achieving the desired outcome:

Solvent Printing: Ideal for long-term outdoor applications requiring durability.

Eco-Solvent Printing: Suitable for indoor or environmentally conscious projects.

UV Printing: Best for high-resolution images, vivid colors, and outdoor longevity.

Latex Printing: Combines eco-friendliness with versatility, perfect for indoor or semi-permanent outdoor displays.

Screen Printing: Effective for bold, high-opacity designs with fewer colors.

Consider banner material, application environment, and visual requirements when choosing the printing method to maximize both impact and lifespan.

5.4 Cost Analysis

Cost is a critical consideration when selecting PVC flex banners, but it should be balanced with quality and longevity:

Material Costs: Higher-density or specialty banners (reflective, blockout, double-sided) are more expensive but offer longer-term durability.

Printing Costs: Advanced methods like UV or latex printing provide superior visual quality but may increase upfront costs.

Installation and Maintenance Costs: Consider whether the banner requires special mounting, frequent cleaning, or repair, which can affect total investment.

Long-Term ROI: Choosing a durable banner with proper printing techniques can reduce replacement frequency, making it more cost-effective over time.

By analyzing costs alongside specifications and intended use, businesses can make strategic investments that deliver maximum visibility, durability, and value.

Summary

Choosing the right PVC flex banner involves careful evaluation of use, specifications, printing techniques, and costs. Key steps include:

Assess indoor vs. outdoor application and environmental exposure.

Determine size, thickness, and material strength based on installation requirements.

Match the printing technique to the material and design complexity.

Evaluate cost-effectiveness, considering long-term durability and maintenance.

A well-chosen PVC flex banner ensures high-quality visuals, longevity, and effective communication, whether for advertising, events, or safety signage. Investing time in the selection process helps brands achieve optimal impact while minimizing costs and maintenance challenges.

Installation and Maintenance of PVC Flex Banners

Proper installation and maintenance are crucial for maximizing the lifespan, appearance, and effectiveness of PVC flex banners. Even the highest-quality banners can deteriorate prematurely if they are not installed correctly or maintained regularly. This section explores best practices for hanging, mounting, cleaning, storage, and minor repairs.

6.1 Installation Techniques

PVC flex banners can be installed in multiple ways depending on the location, size, and purpose. Proper installation ensures stability, visibility, and longevity.

Hanging

Grommet Installation: Grommets are reinforced holes in the banner edges that allow it to be hung with ropes, hooks, or zip ties.

Suspended Banners: Ideal for indoor venues or trade shows, where banners hang from ceilings or over walkways.

Pole Mounting: Street banners or outdoor displays often require banners to be secured to poles using brackets or straps.

Hanging methods must account for wind load and movement, especially outdoors, to prevent tearing or sagging.

Mounting

Frame Mounting: PVC banners can be attached to aluminum or steel frames, providing a professional and sturdy display.

Wall Mounting: Using adhesive tapes, brackets, or rails, banners can be secured directly to walls or building facades.

Lightbox or Display Cases: Backlit banners benefit from being mounted in lightboxes, ensuring even illumination and visibility.

Proper mounting ensures banners remain flat, taut, and visually appealing, enhancing their advertising impact.

Using Banner Stands

Roll-Up Stands: Ideal for trade shows, retail signage, and portable displays, allowing for easy setup and storage.

X-Banners and L-Banners: Lightweight and easy to assemble, suitable for indoor promotions and events.

Banner stands provide mobility, reusability, and flexibility, making them a popular choice for short-term campaigns.

6.2 Maintenance Tips

Regular maintenance helps preserve the quality and longevity of PVC flex banners, ensuring they continue to look professional and impactful.

Cleaning

Use mild soap and water to remove dirt, dust, or stains.

Avoid harsh chemicals or abrasive tools, which can damage the PVC surface or print.

For outdoor banners, periodic cleaning prevents UV damage, fading, and mold buildup.

Storage

Roll banners carefully with the printed side out to avoid creases or scratches.

Store in a cool, dry, and dark environment to prevent UV fading or moisture damage.

For long-term storage, use protective covers or tubes to maintain the banner’s integrity.

Repairing Minor Damage

Small tears can be repaired using PVC adhesive or heat welding techniques.

Loose grommets can be reinforced or replaced to maintain hanging stability.

Regularly inspect for wear and tear, especially after severe weather or frequent handling.

Proper maintenance not only prolongs the banner’s life but also reduces replacement costs and ensures that the banner continues to deliver high-impact visuals.

Summary

Effective installation and maintenance of PVC flex banners involve:

Selecting the appropriate hanging, mounting, or stand method based on the location and banner size.

Regularly cleaning and inspecting banners to prevent dirt buildup, fading, or damage.

Proper storage and handling to avoid creases, scratches, or environmental degradation.

Addressing minor repairs promptly to extend the banner’s lifespan.

By following these practices, businesses and event organizers can ensure that PVC flex banners remain durable, visually striking, and functional throughout their intended use, whether for outdoor advertising, trade shows, or special events.

PVC flex banners are versatile, durable, and cost-effective advertising solutions suitable for a wide range of applications, from outdoor billboards and building wraps to indoor trade shows, event signage, and vehicle wraps. Made from polyvinyl chloride (PVC) with a reinforced polyester or fabric core, they offer tear resistance, weatherproofing, and flexibility for large-format printing. Banners are available in glossy or matte finishes, frontlit, backlit, or blockout designs, and specialty types like reflective or double-sided printable banners, allowing tailored solutions for different needs.

Printing options include solvent, eco-solvent, UV, latex, and screen printing, each chosen based on image quality, environmental considerations, and durability requirements. Proper installation techniques—including hanging, mounting, and using banner stands—along with regular maintenance and storage, ensure longevity and professional appearance.

When selecting a PVC flex banner, factors such as intended use, size, weave density, printing method, and cost should be carefully evaluated. Despite environmental concerns associated with PVC production, recycling initiatives and eco-friendly printing methods are increasingly available. Overall, PVC flex banners remain a reliable and impactful medium for brand promotion, event communication, and safety signage, combining visual appeal with practical performance for both short-term campaigns and long-term advertising solutions.

English

English русский

русский Français

Français Español

Español