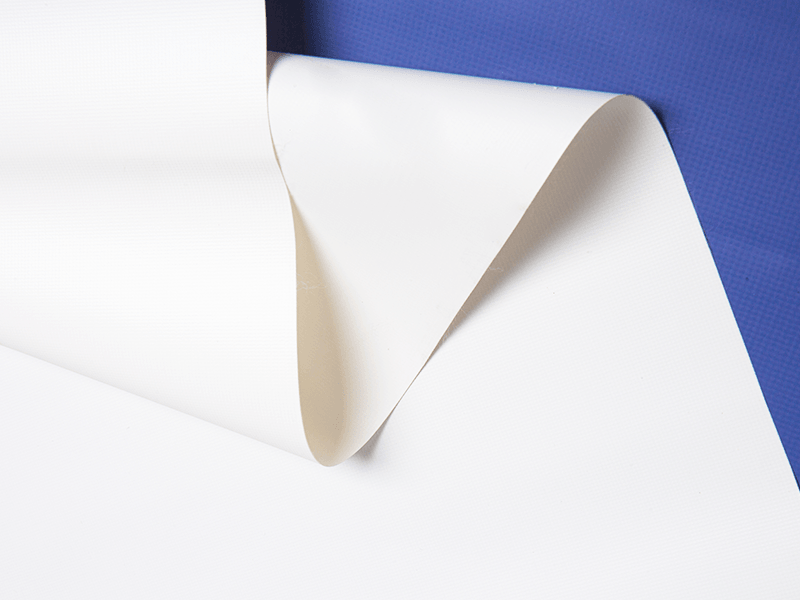

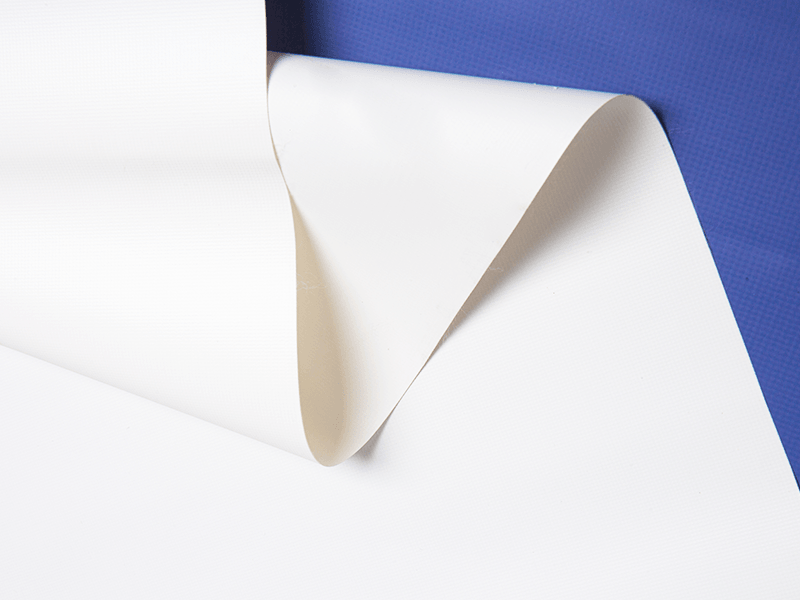

PVC fabric is a polyester or nylon base material coated with polyvinyl chloride, creating a highly durable, waterproof, and weather-resistant textile. When used for tents, PVC fabric typically consists of a woven polyester mesh laminated between two layers of PVC coating, resulting in a material with tensile strength ranging from 2,000 to 5,000 N/5cm and complete waterproofing capabilities. This engineered fabric has become the industry standard for commercial tents, event shelters, and heavy-duty outdoor structures due to its exceptional longevity and protective properties.

Understanding PVC Fabric Construction

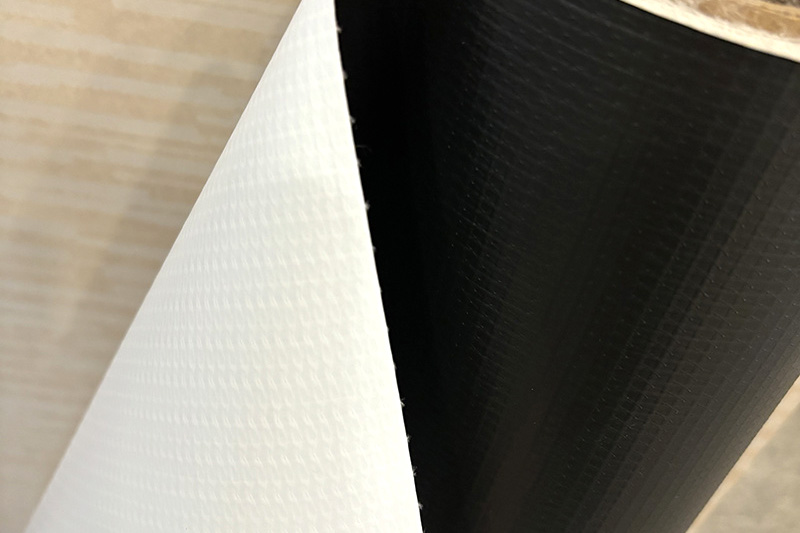

PVC fabric manufacturing involves a sophisticated layering process that transforms ordinary textile into a high-performance material. The base fabric, typically woven from polyester yarns with 1000D to 1500D denier, provides structural integrity and dimensional stability.

Layer Composition

The multi-layer construction consists of three primary components working in synergy:

- Top PVC coating layer (150-300 gsm) providing UV resistance and color retention

- Central woven polyester mesh (200-500 gsm) delivering tensile strength

- Bottom PVC coating layer (150-300 gsm) ensuring waterproofing and abrasion resistance

This triple-layer design results in tent fabric weighing between 500 to 1,100 grams per square meter, with heavier weights offering greater durability for permanent or semi-permanent installations.

Key Performance Characteristics of Tent PVC

Waterproof Performance

PVC-coated tent fabrics achieve 100% waterproof ratings with hydrostatic head pressures exceeding 5,000mm, far surpassing the 1,500mm threshold considered waterproof. In practical terms, this means the material can withstand heavy rainfall of 100mm per hour without any water penetration, making it reliable for all-weather outdoor events.

Durability and Lifespan

Quality PVC tent fabric demonstrates remarkable longevity in outdoor applications. Field studies show that properly maintained PVC tents can last 10 to 15 years in permanent installations and 15 to 20 years with seasonal use. The material resists tearing with tear strength values of 200-400 N and maintains structural integrity even when subjected to wind speeds of 80-100 km/h.

Temperature Tolerance

PVC fabric maintains flexibility and performance across temperature ranges from -30°C to +70°C, making it suitable for diverse climatic conditions from arctic environments to desert regions. The material does not become brittle in freezing conditions or excessively soft in high heat.

Comparison with Alternative Tent Materials

| Material Type | Waterproof Rating | Lifespan (Years) | Weight (gsm) | UV Resistance |

|---|---|---|---|---|

| PVC Coated Fabric | 5,000+ mm | 10-20 | 500-1,100 | Excellent |

| Polyester Canvas | 1,500-3,000 mm | 5-8 | 200-400 | Good |

| PE Tarpaulin | 3,000-4,000 mm | 2-4 | 150-300 | Moderate |

| Cotton Canvas | 800-1,500 mm | 3-6 | 300-500 | Poor |

The data clearly demonstrates why PVC fabric dominates the commercial tent market, offering 2-5 times longer lifespan than conventional alternatives while maintaining superior waterproofing and weather resistance.

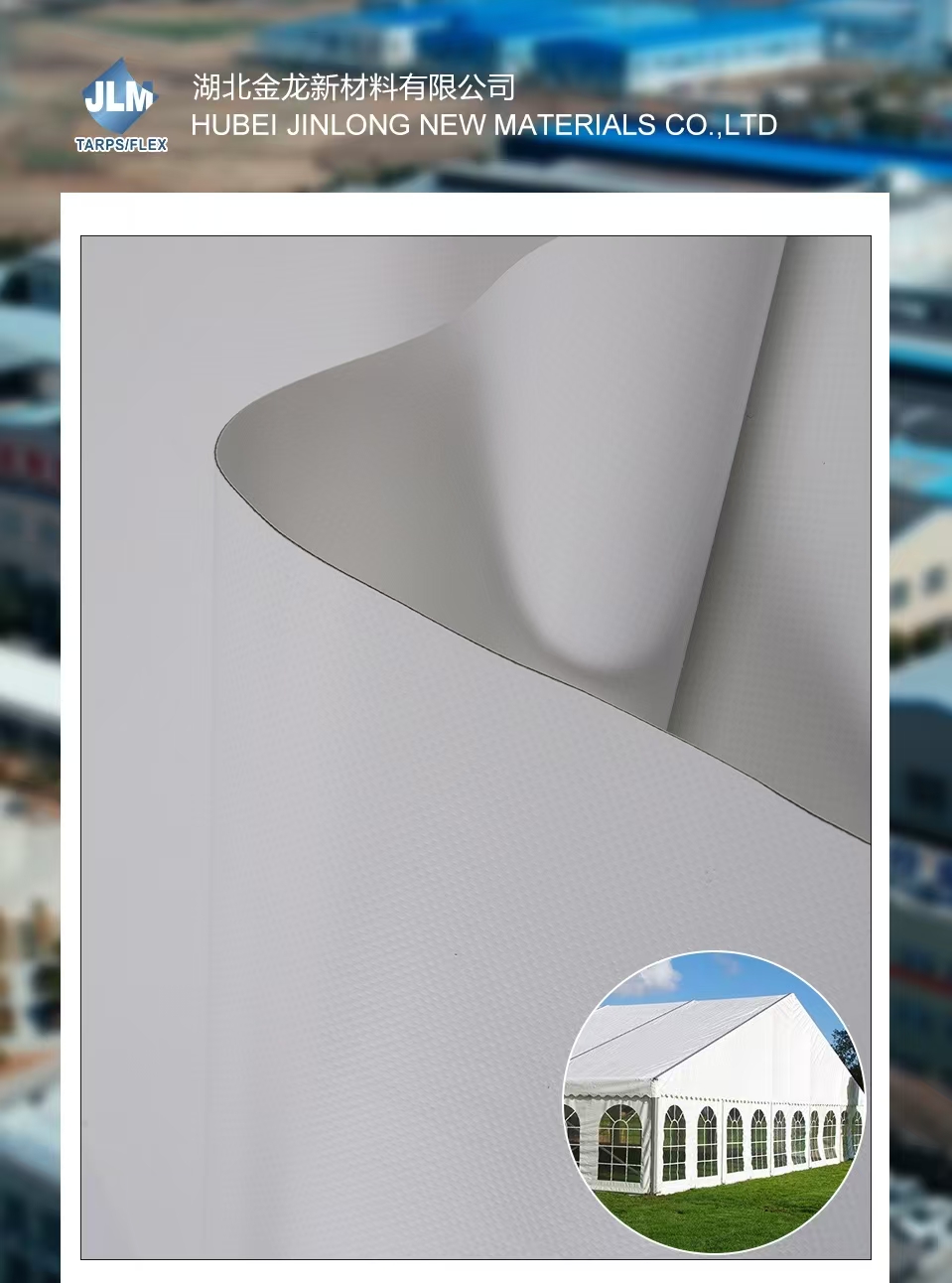

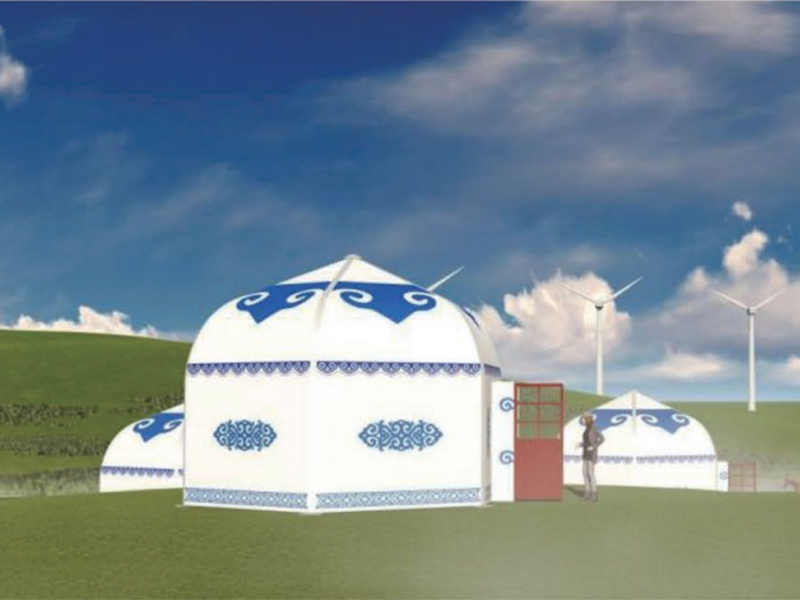

Common Applications for PVC Tent Fabric

Event and Commercial Tents

PVC fabric serves as the primary material for wedding marquees, exhibition tents, and outdoor event structures. The fabric's ability to span large areas without internal supports—clear spans of up to 50 meters are achievable—makes it ideal for creating spacious, column-free interiors. Event companies report that PVC tents withstand over 200 setup and takedown cycles while maintaining structural integrity.

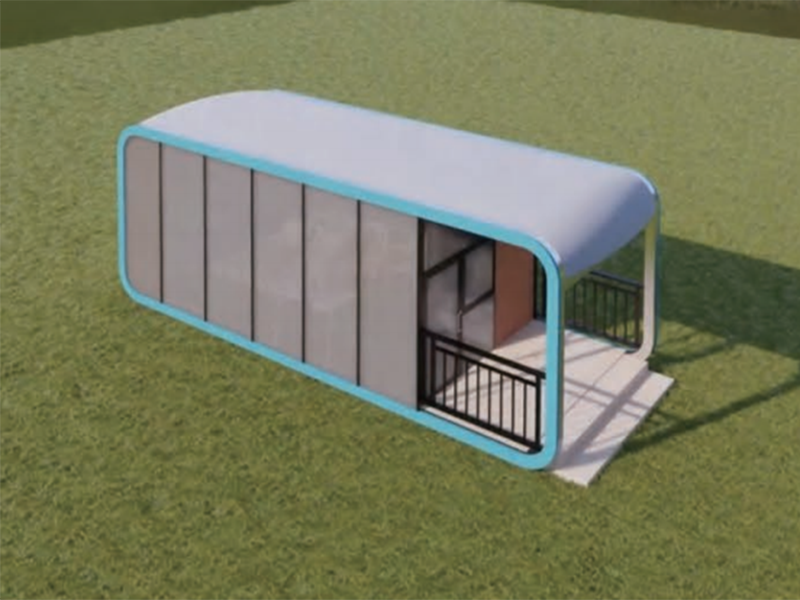

Industrial and Storage Structures

Warehouses, machinery covers, and temporary storage facilities utilize heavy-duty PVC fabric (850-1,100 gsm) for protection against environmental elements. These structures provide cost-effective alternatives to permanent buildings, with installation costs typically 40-60% lower than traditional construction while offering comparable weather protection.

Sports and Recreation Facilities

Tennis court covers, swimming pool enclosures, and seasonal sports halls rely on PVC fabric's translucency to provide natural daylight while blocking harmful UV radiation. Modern PVC fabrics can transmit 10-30% of visible light depending on color and opacity, reducing artificial lighting requirements by up to 70% during daylight hours.

Maintenance and Care Guidelines

Proper maintenance significantly extends the functional life of PVC tent fabric. Regular cleaning with mild detergent and water prevents accumulation of organic matter that can degrade the PVC coating. Industry best practices recommend:

- Surface cleaning every 3-6 months using pH-neutral cleaners

- Inspection of seams and stress points every 6 months

- Removal of standing water and debris after severe weather

- Storage in dry, ventilated conditions when not in use

- Application of UV-protective treatments every 2-3 years for permanent installations

Facilities that follow these protocols report 30-40% longer fabric lifespan compared to those with minimal maintenance routines.

Environmental Considerations and Fire Safety

Fire Retardant Properties

Modern PVC tent fabrics incorporate fire-retardant additives that meet international safety standards including NFPA 701, CPAI-84, and EN 13501-1 Class B1/M2 certifications. These treatments prevent flame spread and ensure self-extinguishing behavior, with most quality fabrics achieving flame spread ratings below 25 on the ASTM E84 scale.

Recyclability and Disposal

While PVC fabric poses recycling challenges, industry initiatives have developed mechanical recycling processes that can recover up to 85% of the polyester base material. Specialized recycling facilities separate the PVC coating from the polyester mesh through thermal or chemical processes, allowing both components to be reprocessed into new products. End-of-life PVC fabric can also be downcycled into products like automotive undercoating, floor mats, or industrial sheeting.

Selecting the Right PVC Fabric Weight

Choosing appropriate fabric weight depends on specific application requirements and environmental conditions:

- 500-650 gsm: Temporary event tents, market stalls, seasonal canopies with expected use of 1-3 years

- 650-850 gsm: Semi-permanent structures, wedding marquees, exhibition tents requiring 5-10 years durability

- 850-1,100 gsm: Permanent installations, industrial warehouses, sports facilities demanding 10-20 years lifespan

Heavier fabrics provide superior wind resistance and longevity but increase structural support requirements and installation complexity. Engineering calculations show that upgrading from 650 gsm to 850 gsm fabric increases wind load capacity by approximately 35-40%.

Cost Analysis and Return on Investment

Initial material costs for PVC tent fabric range from $8 to $25 per square meter depending on weight, quality, and additional treatments. While this represents a higher upfront investment than polyethylene or basic polyester alternatives, the total cost of ownership favors PVC fabric significantly.

A 500-square-meter event tent using 850 gsm PVC fabric costs approximately $12,000 in materials but delivers 12-15 years of service. Comparable PE tarpaulin fabric at $3,000 requires replacement every 2-3 years, resulting in total material costs of $15,000-$18,000 over the same period, not accounting for labor costs associated with multiple replacements.

Commercial tent rental companies report that PVC tents pay for themselves within 18-24 months through rental revenue, compared to 30-36 months for lighter-weight alternatives that require more frequent replacement and repairs.

English

English русский

русский Français

Français Español

Español