1. What is a PVC Flex Banner?

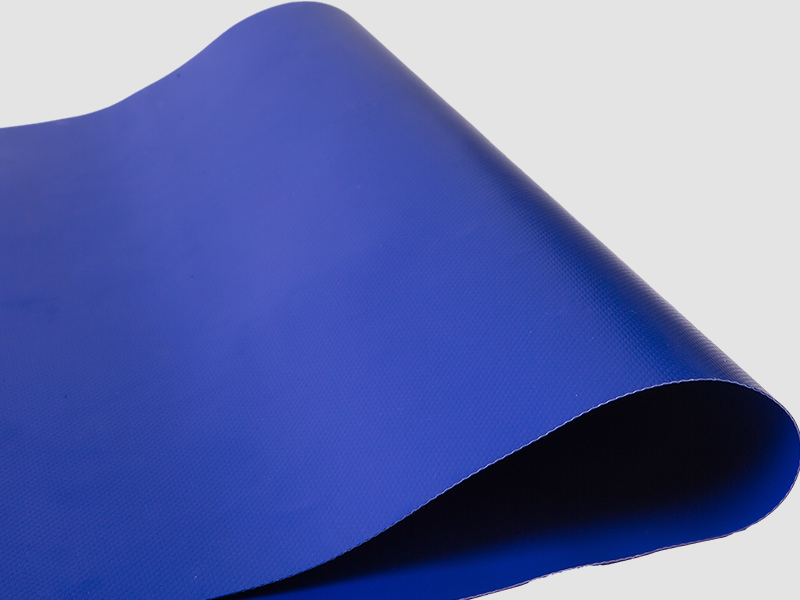

A PVC Flex Banner is a durable and flexible material made primarily from polyvinyl chloride (PVC) film laminated onto a polyester base fabric. It is widely used for outdoor and indoor advertising displays, including billboards, signage, trade show graphics, and promotional backdrops. The banner combines high tensile strength, weather resistance, and excellent printability, making it a top choice for large-format digital printing.

Because of its flexibility and ease of customization, PVC Flex Banner has become a cornerstone of the advertising and display industry. It supports high-resolution graphics, vibrant colors, and various finishes, from matte to glossy, to suit different environmental and visual needs.

2. Types of PVC Flex Banner Based on Manufacturing

The performance of a PVC Flex Banner depends greatly on how it is manufactured. There are several main types, each serving specific display requirements.

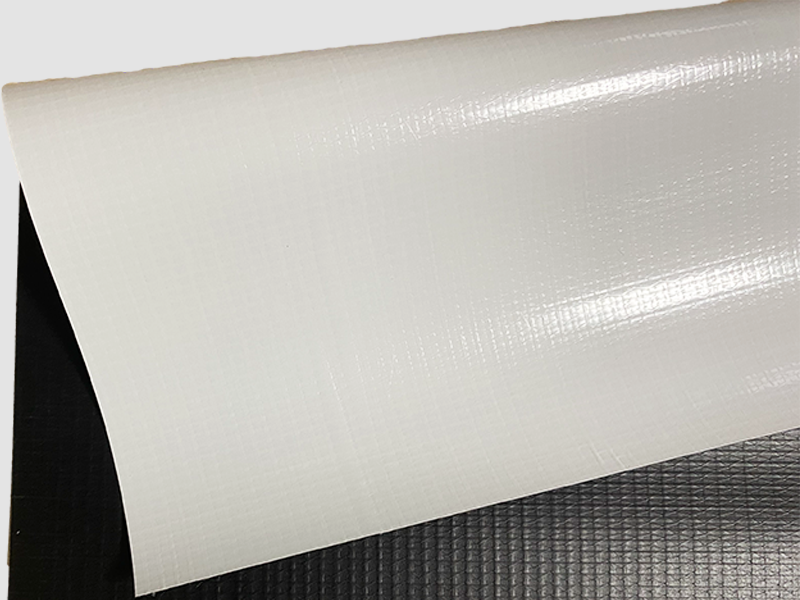

2.1 Laminated PVC Flex Banner

This type is made by laminating two layers of PVC film with a polyester scrim in between. It is economical, lightweight, and suitable for short-term outdoor and indoor advertising. However, it is less resistant to tearing compared to coated banners.

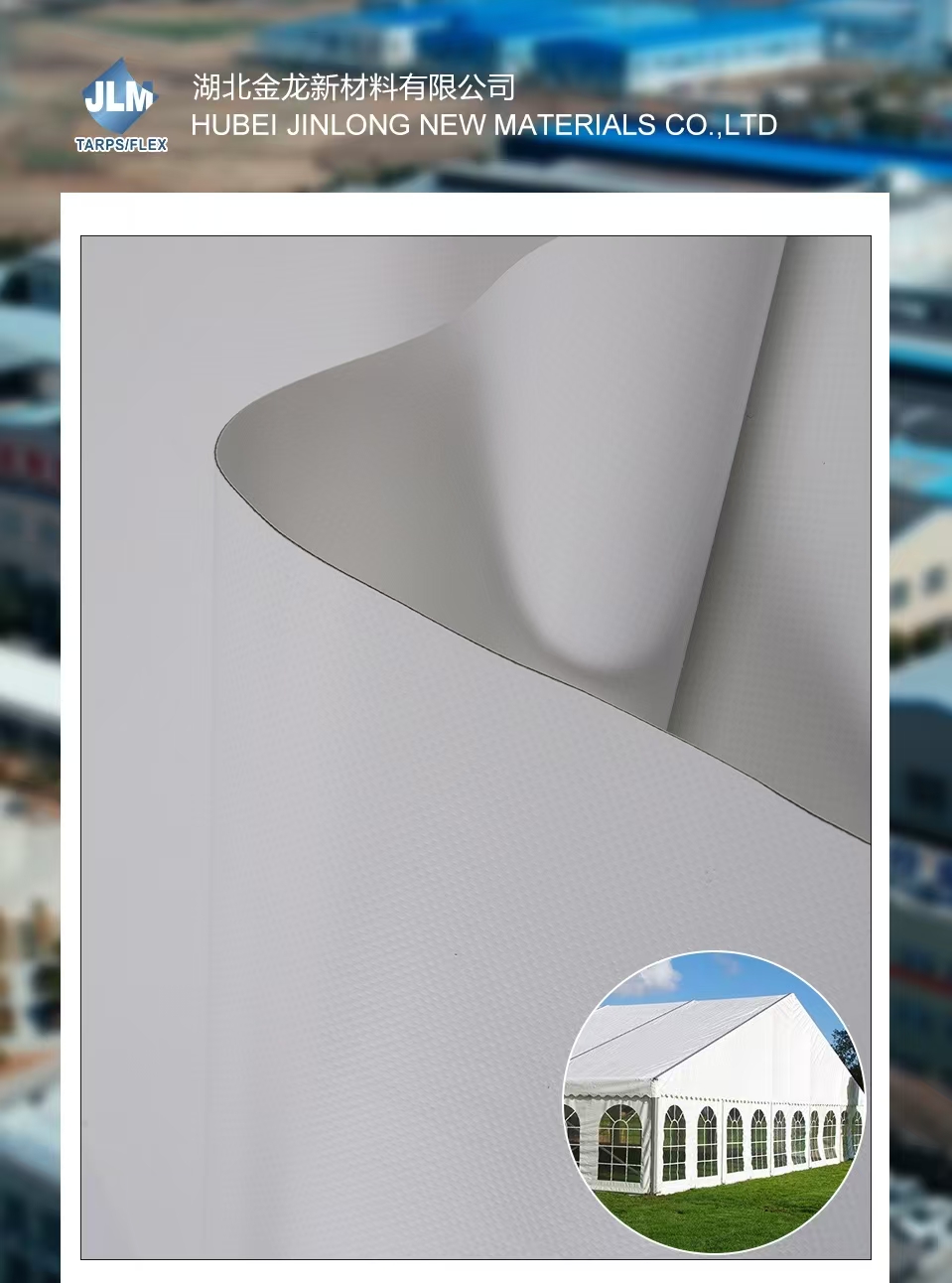

2.2 Coated PVC Flex Banner

A coated banner involves directly coating liquid PVC onto the polyester base fabric. This process enhances adhesion, flexibility, and weather resistance. It is recommended for high-end, long-term applications such as building wraps and outdoor billboards exposed to wind and sunlight.

2.3 Mesh PVC Flex Banner

Mesh banners feature small perforations that allow air to pass through, reducing wind load and preventing tearing. These are ideal for high-rise installations, building façades, and outdoor events where wind pressure is a concern.

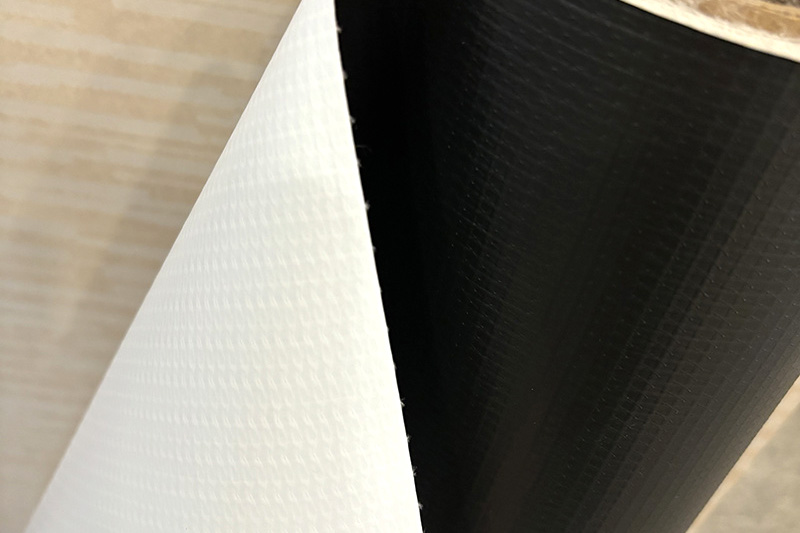

2.4 Blockout PVC Flex Banner

Blockout banners contain an opaque layer between two PVC films, preventing light transmission. They are perfect for double-sided printing and ensuring that graphics remain vibrant even in strong backlight conditions.

3. Material Composition and Technical Properties

A typical PVC Flex Banner combines synthetic materials that work together to provide strength, flexibility, and print quality. The table below shows a common structure and property overview.

| Component | Material | Function |

| Front Layer | PVC Film | Provides a printable surface and weather protection |

| Base Fabric | Polyester Scrim | Gives mechanical strength and tear resistance |

| Back Layer | PVC Coating | Ensures durability and dimensional stability |

These layers are bonded under controlled heat and pressure to create a smooth, strong, and UV-resistant banner suitable for solvent, eco-solvent, latex, and UV printing methods.

4. Printing Methods for PVC Flex Banner

Choosing the right printing technique ensures that a PVC Flex Banner delivers high visual impact and longevity. Below are the most common printing options used in the market:

- Solvent Printing: Ideal for outdoor banners requiring UV resistance and water durability. Produces vibrant colors but releases VOCs during printing.

- Eco-Solvent Printing: A more environmentally friendly version of solvent printing, providing sharp images and weather-resistant ink adhesion.

- UV Printing: Uses ultraviolet-curable inks for high-speed production and superior scratch resistance. Suitable for both indoor and outdoor use.

- Latex Printing: Offers excellent image quality and eco-safety, with inks that dry instantly and resist fading under sunlight.

5. Applications of PVC Flex Banner

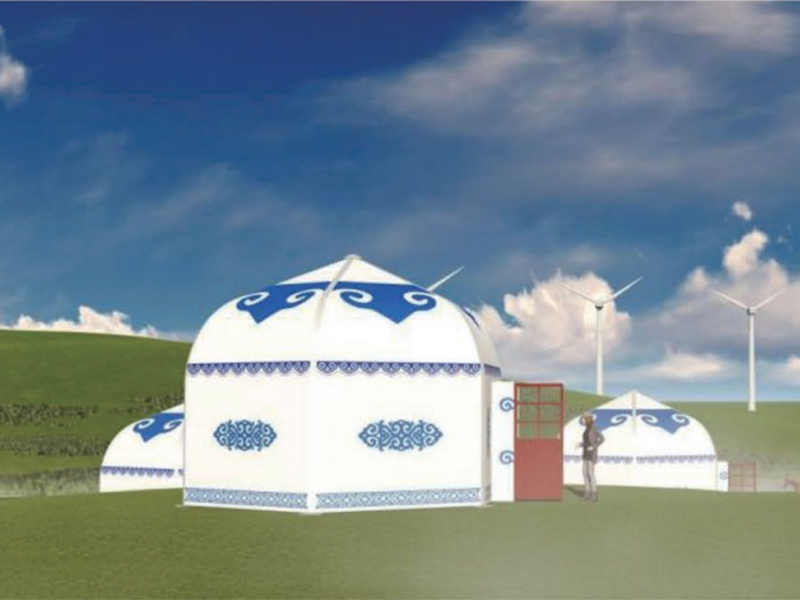

PVC Flex Banners are incredibly versatile and can be used in a wide range of advertising and decorative environments. Common applications include:

| Application Area | Examples of Use |

| Outdoor Advertising | Billboards, building wraps, roadside signage |

| Indoor Promotions | Trade show backdrops, retail posters, event displays |

| Construction Sites | Mesh banners for scaffolding covers or fencing graphics |

| Public Events | Concerts, exhibitions, sports arenas |

6. Advantages of Using PVC Flex Banner

PVC Flex Banners are popular due to their practicality, cost-effectiveness, and adaptability. The following advantages highlight why they are a preferred material in global advertising:

- Excellent print surface ensuring vibrant and long-lasting colors.

- High weather, UV, and moisture resistance for outdoor durability.

- Available in various thicknesses and widths for different display formats.

- Can be welded, stitched, or eyeleted for easy installation.

- Supports multiple printing technologies, increasing production flexibility.

- Reusable and recyclable options available with eco-friendly formulations.

7. Maintenance and Storage Tips

Proper handling of PVC Flex Banners extends their life and maintains color brilliance. Follow these guidelines for maintenance:

- Clean banners with mild soap and water — avoid abrasive cleaners.

- Roll banners instead of folding to prevent creases or cracks.

- Store in a cool, dry place away from direct sunlight and high humidity.

- Avoid prolonged contact with sharp edges or heavy objects that may damage the surface.

8. How to Choose the Right PVC Flex Banner

Selecting the right banner depends on the environment, display duration, and printing method. The table below offers a quick comparison guide for different banner types.

| Banner Type | Best Use Case | Durability |

| Laminated | Short-term indoor/outdoor advertising | Medium |

| Coated | Long-term outdoor displays and billboards | High |

| Mesh | Windy areas and building wraps | High |

| Blockout | Double-sided printing applications | High |

9. Conclusion: The Versatility of PVC Flex Banner

PVC Flex Banner remains one of the most practical and affordable solutions for advertising and branding. Its combination of durability, print quality, and adaptability allows businesses to create eye-catching graphics for any setting. Whether used for a small indoor display or a massive outdoor billboard, a well-chosen PVC Flex Banner ensures lasting visibility and professional presentation, making it an indispensable medium in modern visual marketing.

English

English русский

русский Français

Français Español

Español