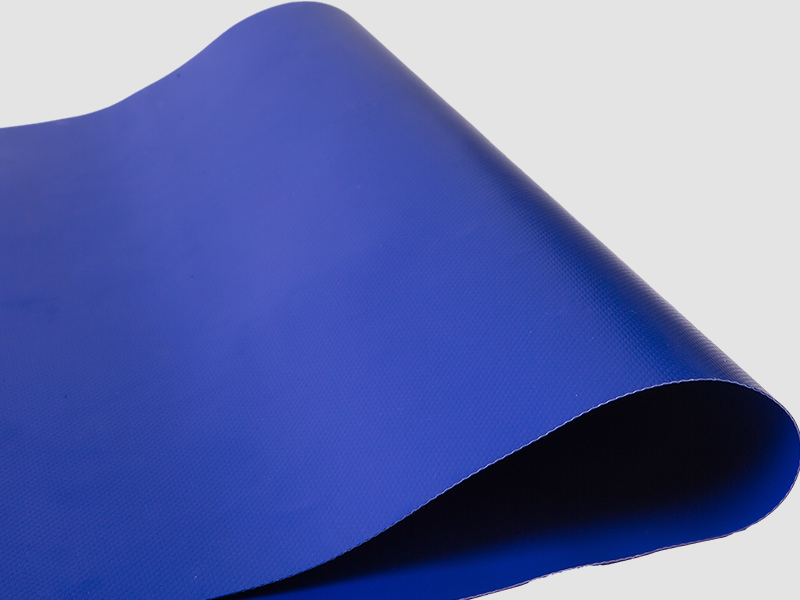

PVC coated tarpaulin, a widely used material in outdoor protection, transportation, and industrial applications, is known for its durability, waterproof properties, and versatility. One of the key concerns for manufacturers, buyers, and users is its fire resistance performance. Understanding how PVC coated tarpaulin behaves under fire conditions, its safety features, and practical implications is essential for ensuring safe use in various applications.

1. Composition and Fire-Resistant Properties

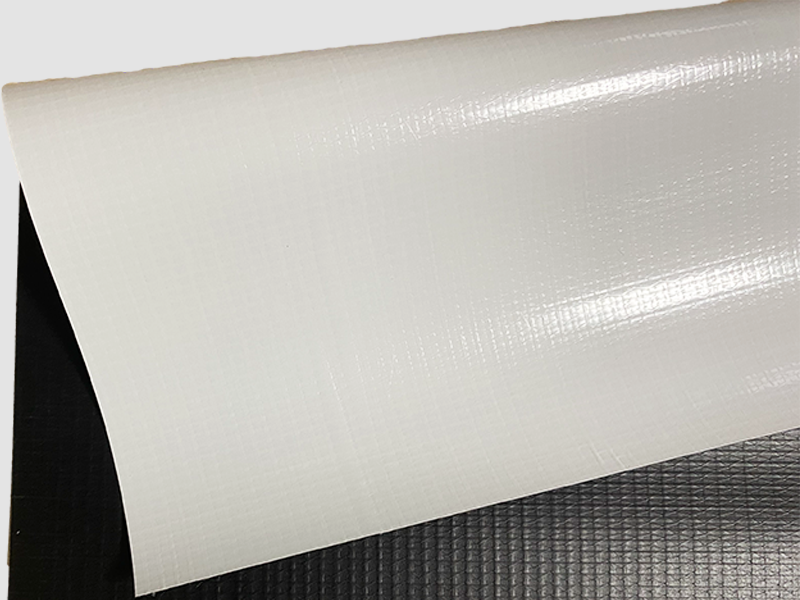

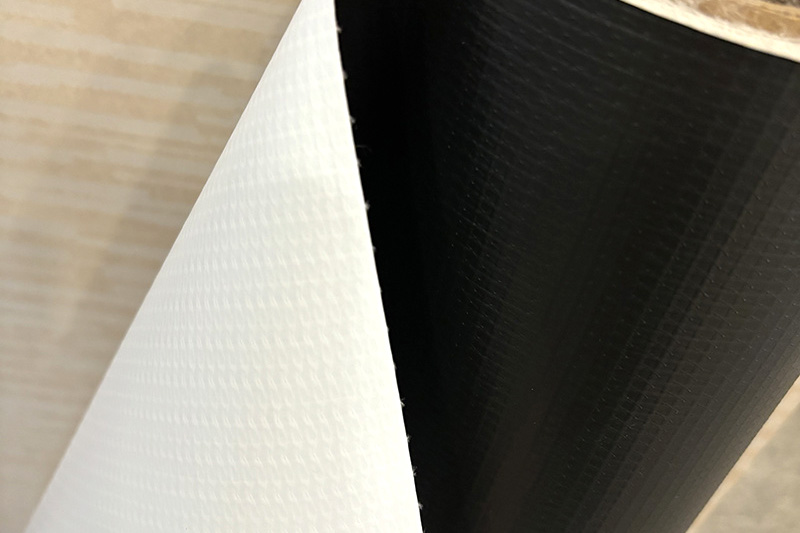

PVC coated tarpaulin is made by coating a base fabric (usually polyester or nylon) with polyvinyl chloride (PVC). This composition provides several fire-resistant properties:

- PVC is inherently flame-retardant: Polyvinyl chloride contains chlorine, which helps inhibit ignition and slows down flame spread.

- Self-extinguishing behavior: When exposed to an open flame, PVC coated tarpaulin often melts or chars but does not continue burning once the heat source is removed.

- Reduced smoke and toxic gas emission: High-quality PVC formulations are engineered to minimize smoke production and the release of toxic gases during combustion.

These characteristics make PVC coated tarpaulin safer than many untreated fabrics, particularly in outdoor, industrial, and transport applications where fire hazards may exist.

2. Fire Resistance Standards and Testing

To ensure safety, PVC coated tarpaulins are often tested according to international fire resistance standards:

- ISO 3795: Tests the flammability of materials used in road vehicles, assessing burning rate and flame propagation.

- DIN 4102: A German standard classifying building materials based on fire behavior, including B1 (flame-retardant) classification for PVC tarpaulins.

- BS 7837: British standard for fire-retardant fabrics in public transport.

High-quality PVC coated tarpaulins usually meet these standards, demonstrating slow flame propagation, minimal smoke, and limited heat release, making them suitable for various applications requiring fire safety compliance.

3. Practical Fire Resistance Performance

In real-world applications, PVC coated tarpaulin shows several advantages:

- Delayed ignition: The chlorine content in PVC slows down the ignition process, providing critical time to remove combustible materials or extinguish flames.

- Self-extinguishing behavior: If the tarpaulin catches fire, it tends to melt or shrink away from the flame, reducing the risk of the fire spreading.

- Limited flame spread: The coated surface prevents the fire from quickly reaching the underlying fabric, unlike untreated polyester or cotton fabrics.

- Reduced toxic emissions: Modern PVC tarpaulins are formulated to minimize harmful fumes, making them safer for outdoor shelters, tents, and industrial covers.

These practical features make PVC coated tarpaulin a reliable material in fire-prone or high-risk environments.

4. Applications Where Fire Resistance Matters

The fire-resistant properties of PVC coated tarpaulin make it suitable for various high-risk applications:

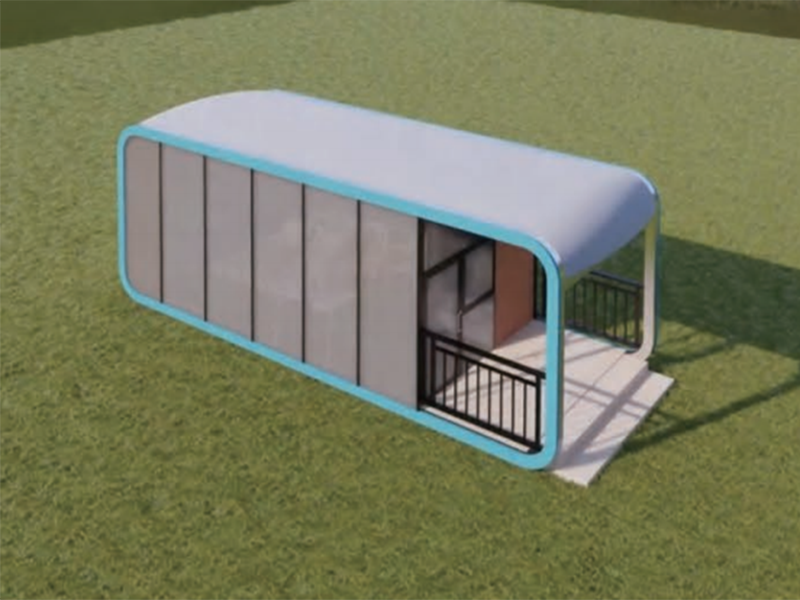

- Industrial covers and machinery protection: Protects equipment from sparks and heat in manufacturing and construction environments.

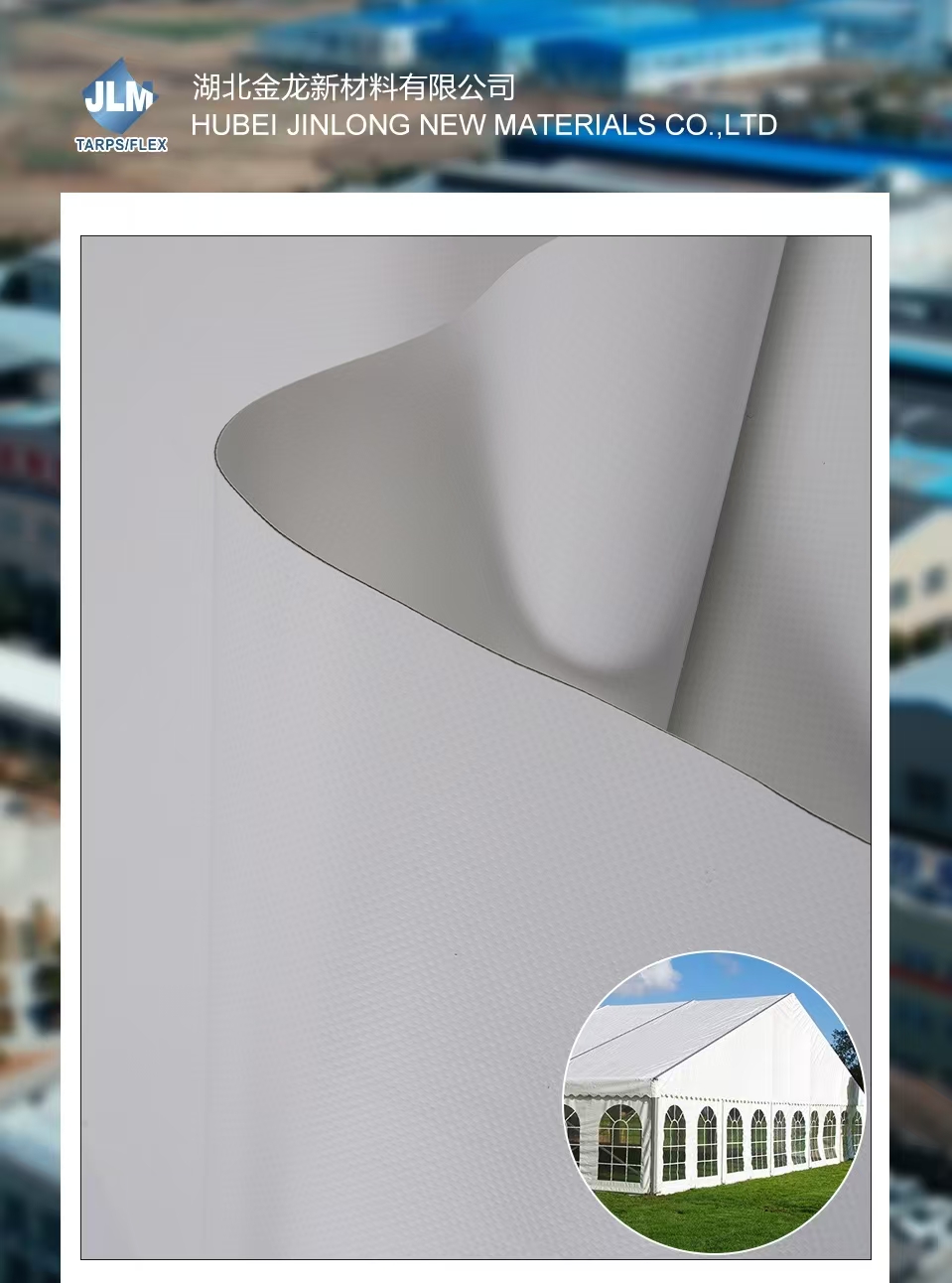

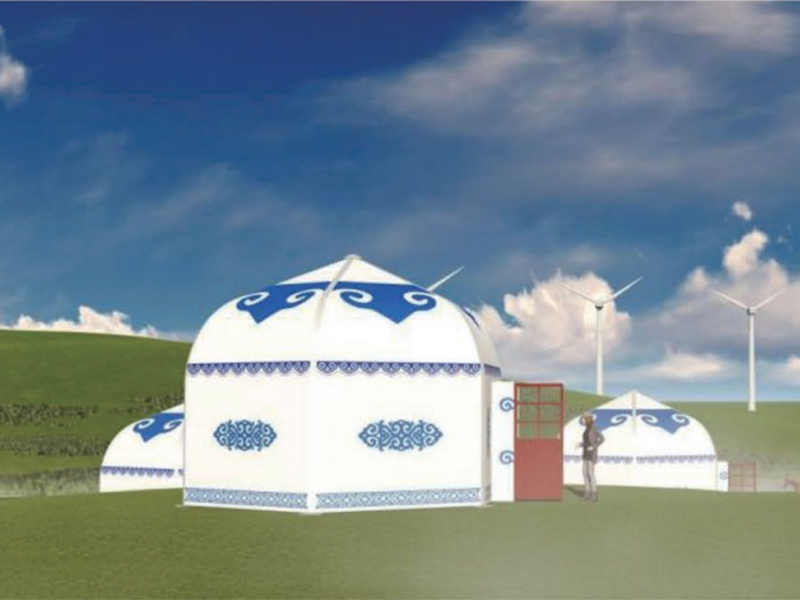

- Outdoor tents and shelters: Provides safer temporary housing and event structures where open flames or cooking may be present.

- Transportation and cargo protection: Used for truck covers and tarpaulin sheets to minimize fire hazards during transit.

- Public areas and commercial spaces: Flame-retardant tarpaulins are preferred for stages, exhibition tents, and canopies to comply with safety regulations.

By using fire-resistant PVC tarpaulins, operators can reduce fire risks and enhance safety for people, property, and goods.

5. Maintenance and Fire Safety Recommendations

While PVC coated tarpaulins are inherently fire-resistant, proper use and maintenance are essential:

- Avoid prolonged exposure to open flames: Even flame-retardant PVC can degrade under direct, prolonged fire.

- Regular inspection: Check for wear, cracks, or thinning of the coating, which may reduce fire resistance.

- Use in combination with safety measures: Fire-resistant tarpaulins should complement fire extinguishers, alarms, and proper handling procedures.

These practices ensure that the fire safety benefits of PVC tarpaulin are maintained over time.

Conclusion

PVC coated tarpaulin demonstrates excellent fire resistance performance due to its PVC composition, which is inherently flame-retardant and self-extinguishing. High-quality tarpaulins meet international fire safety standards, offering delayed ignition, limited flame spread, and reduced toxic emissions. These properties make them ideal for industrial covers, outdoor shelters, transportation, and public-use applications.

Proper selection, maintenance, and use of PVC coated tarpaulins can significantly enhance safety, providing a reliable solution for environments where fire hazards are a concern. Its combination of durability, waterproofing, and fire resistance makes PVC coated tarpaulin a versatile and safe material for modern applications.

English

English русский

русский Français

Français Español

Español