Introduction to PVC Tensile Tent Fabric

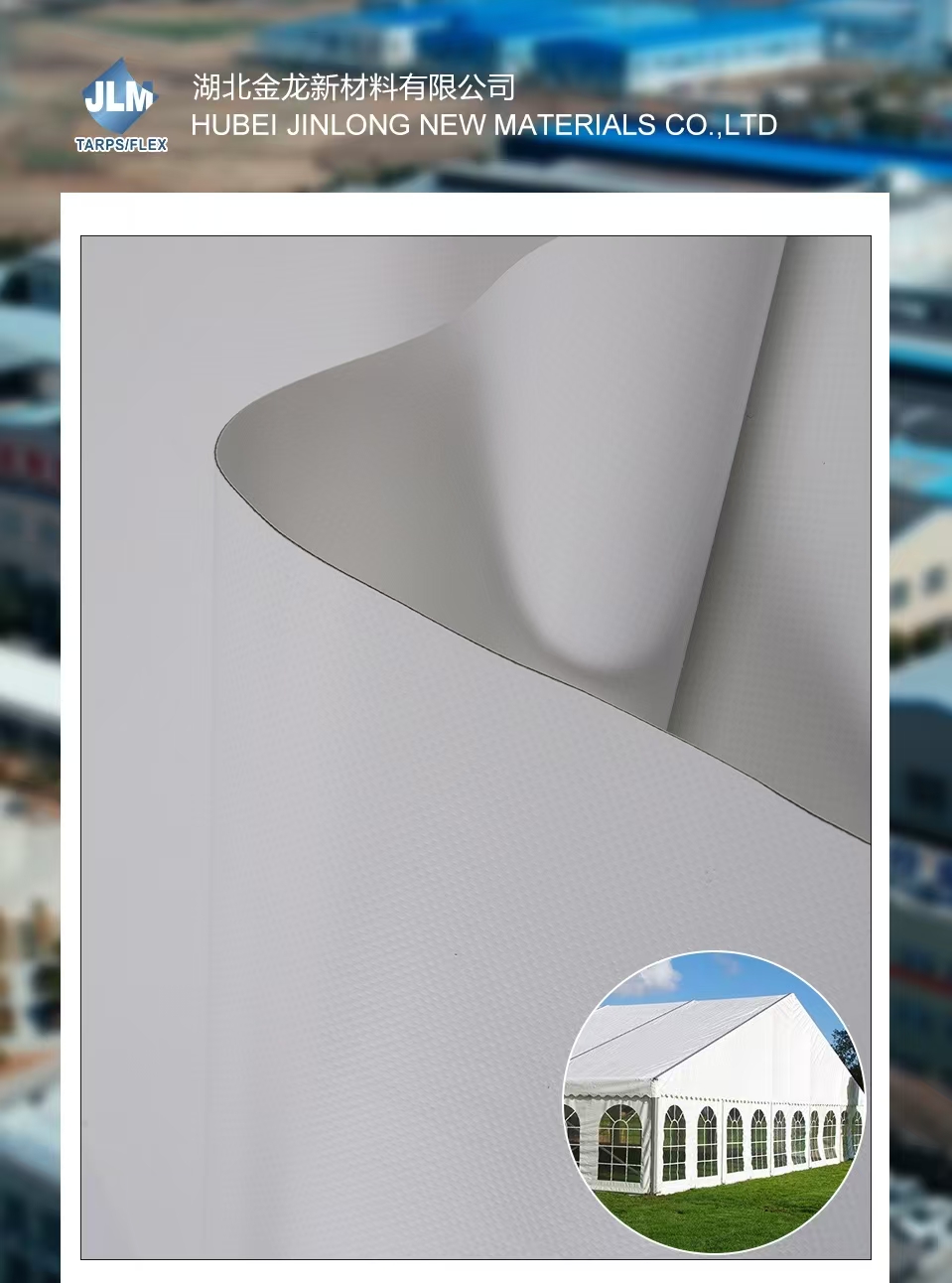

PVC tensile tent fabric is a high-performance material widely used in outdoor tents, pavilions, and commercial tensile structures. Known for its strength, flexibility, and resistance to environmental conditions, this fabric is particularly valued for its waterproofing capabilities, which make it ideal for protecting people and equipment from rain and moisture.

Waterproofing Properties of PVC Tensile Fabric

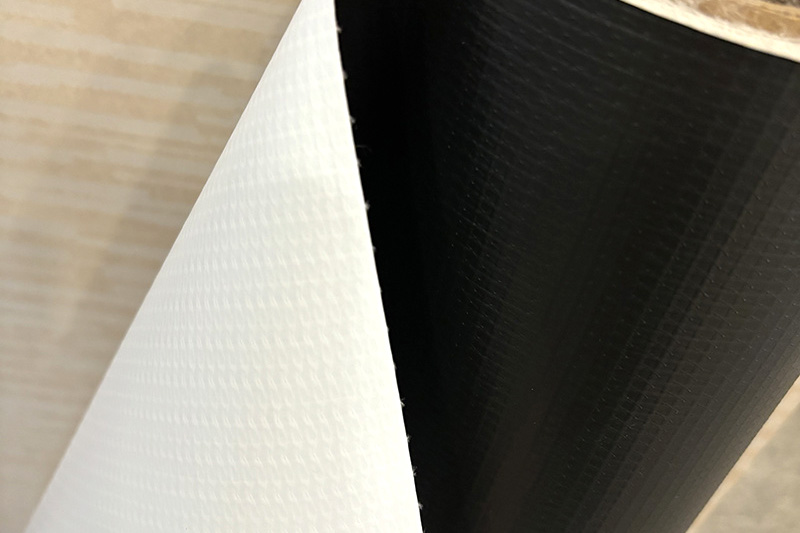

The primary factor that defines the waterproof performance of PVC tensile fabric is its construction and surface coating.

PVC Coating and Lamination

PVC tensile fabrics are coated with a thin layer of polyvinyl chloride (PVC) that forms a water-resistant barrier. This coating prevents water from penetrating the fabric while maintaining flexibility and tensile strength, even under heavy rainfall.

Seam Sealing Techniques

Seams are the most vulnerable areas for water ingress. Advanced PVC tensile tents use heat-welded or ultrasonic-sealed seams, ensuring that no water leaks through the stitching lines. Proper seam sealing significantly enhances the waterproof rating of the tent fabric.

Testing Waterproof Performance

PVC tensile fabrics undergo rigorous testing to measure their waterproof capacity. Standard tests simulate heavy rainfall and water pressure to determine the fabric’s resistance.

Hydrostatic Head Test

The hydrostatic head test measures the height of a water column the fabric can withstand before leakage occurs. High-quality PVC tensile fabrics typically achieve hydrostatic head values of 500–1000 mm, indicating strong waterproof performance suitable for outdoor applications.

Real-World Rain Simulation

Simulated rain tests expose the tent fabric to continuous rainfall over several hours. PVC tensile fabric consistently resists water penetration, demonstrating its reliability for camping, events, and commercial structures.

Factors Affecting Waterproof Performance

Several factors can influence the waterproof performance of PVC tensile tent fabric in practical use.

Fabric Thickness and Density

Thicker and denser PVC fabrics offer higher water resistance. Lightweight fabrics may still be waterproof, but their durability and puncture resistance may be lower.

Quality of Coating and Lamination

Uniform PVC coating without cracks or defects ensures consistent waterproofing. Laminated fabrics with protective top layers enhance performance and reduce UV degradation.

Proper Tensioning and Structure Design

PVC tensile fabric works best when correctly tensioned. Sagging areas can collect water, leading to pooling and potential leakage. Designing structures with sufficient slope and drainage ensures optimal waterproof performance.

Maintenance Tips to Preserve Waterproofing

Proper maintenance is essential to maintain the waterproof properties of PVC tensile tent fabric over time.

- Regularly clean the fabric with mild soap and water to remove dirt and debris that can damage the PVC coating.

- Avoid abrasive brushes or high-pressure washing, which can scratch or erode the surface.

- Inspect seams and welds periodically for damage or loosening, and repair immediately using compatible PVC repair kits.

- Store the fabric in a dry, ventilated area when not in use to prevent mold or mildew that can compromise water resistance.

- Apply protective coatings or UV treatments if the fabric is exposed to long-term sunlight, which can degrade the PVC layer over time.

Comparison Table: PVC Tensile Fabric vs Other Tent Fabrics

| Feature | PVC Tensile Fabric | Polyester Fabric | Canvas Fabric |

| Waterproofing | Excellent (Hydrostatic head 500–1000 mm) | Moderate (Requires coating) | Moderate to low (Needs wax or treatment) |

| Durability | High | Medium | High |

| UV Resistance | High | Medium | Low to medium |

| Maintenance | Easy | Moderate | Requires regular treatment |

Applications of Waterproof PVC Tensile Fabric

Thanks to its waterproof performance, PVC tensile tent fabric is widely used in multiple applications:

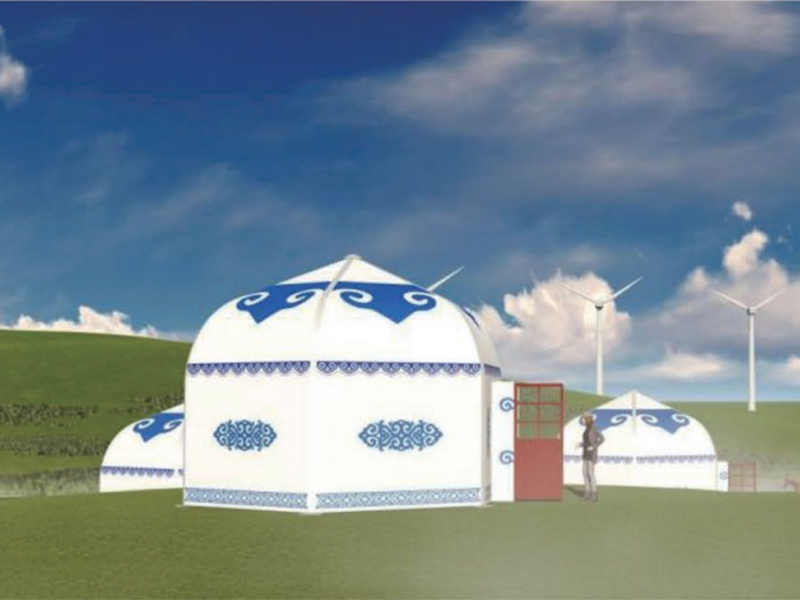

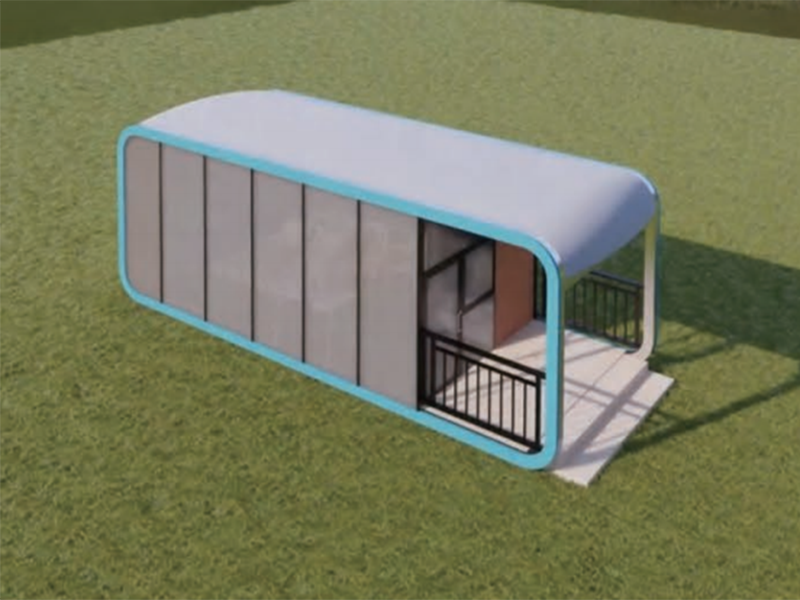

- Outdoor camping tents and shelters

- Commercial pavilions and exhibition tents

- Sports event coverings and temporary stadium roofs

- Canopies, awnings, and pergolas

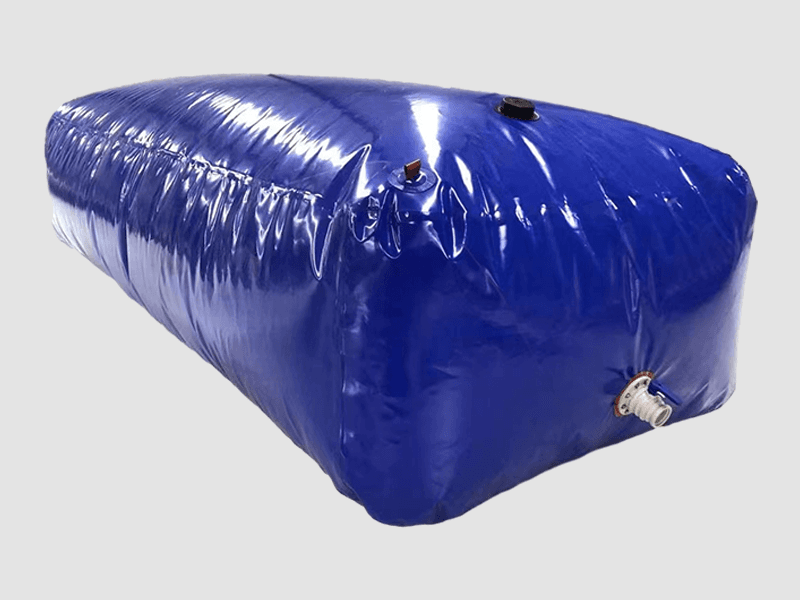

- Water-resistant covers for equipment and vehicles

Conclusion

PVC tensile tent fabric demonstrates excellent waterproof performance due to its durable PVC coating, reinforced seams, and proper structural design. Regular maintenance and careful installation help preserve these properties over time. Its versatility, strength, and water resistance make it an ideal choice for outdoor tents, commercial structures, and protective coverings, ensuring reliability even under heavy rain or harsh environmental conditions.

English

English русский

русский Français

Français Español

Español