Introduction to PVC Inflatable Fabric

PVC inflatable fabric is widely used in outdoor products, from inflatable boats and water toys to air mattresses and advertising inflatables. Its popularity stems from its lightweight, flexible, and durable properties. A key concern for users and manufacturers alike is the fabric's ability to resist water and moisture. Understanding how PVC inflatable fabric achieves waterproofing and moisture resistance is crucial for ensuring product longevity and safety in various environments.

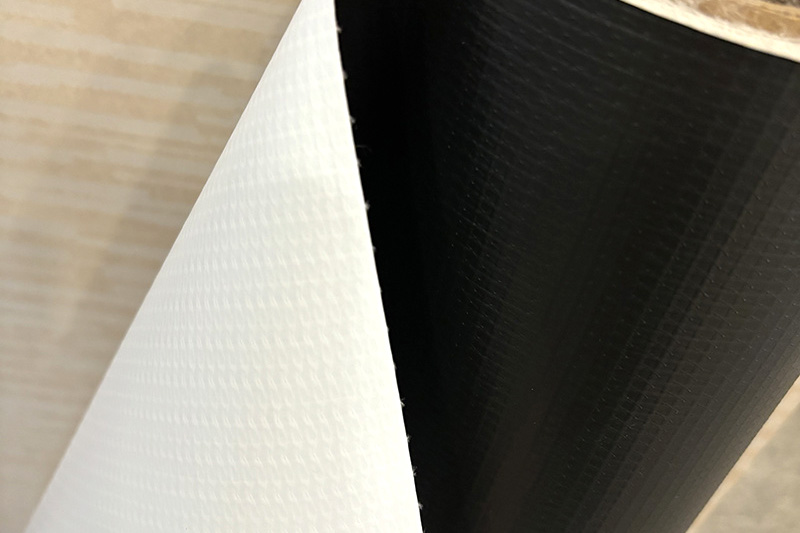

Material Composition and Waterproofing Mechanism

PVC inflatable fabric is composed of polyvinyl chloride (PVC) combined with polyester or nylon reinforcement. The PVC layer forms a continuous, impermeable barrier that prevents water penetration. Reinforced fabrics use woven fibers to add mechanical strength without compromising waterproofing. The combination of these materials ensures that PVC inflatable fabric is highly resistant to water and can maintain air retention under pressure.

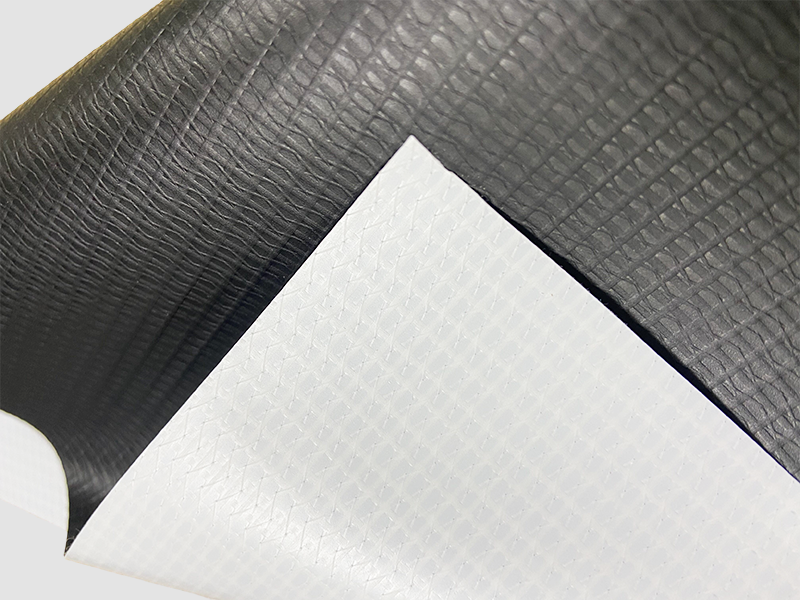

Surface Coatings and Laminations

Many PVC inflatable fabrics are treated with additional coatings or laminations to enhance water resistance and reduce surface friction. These coatings improve performance in wet environments, prevent seepage through seams, and protect against environmental degradation. Laminated PVC fabrics also improve puncture and tear resistance, which is critical for outdoor inflatable products.

Seam Construction and Moisture Resistance

Even if the base fabric is waterproof, seams are often the most vulnerable points for water infiltration. PVC inflatable fabrics employ specialized welding or heat-sealing techniques to create airtight and watertight seams. Ultrasonic welding, hot air welding, or high-frequency sealing ensures that the seam is as strong as the fabric itself, preventing water from seeping through under normal operating conditions.

Comparison of Seam Techniques

| Seam Type | Waterproof Effectiveness | Durability | Typical Applications |

| Heat-Welded | High | Moderate | Air mattresses, inflatable boats |

| Ultrasonic Welding | Very High | High | Premium inflatables, water toys |

| Hot Air Welding | High | High | Large inflatable structures |

Environmental Resistance and Moisture Protection

PVC inflatable fabric is resistant not only to water but also to humidity and environmental moisture. Its dense polymer structure prevents water molecules from penetrating, while the smooth surface discourages mold and mildew growth. Outdoor inflatables benefit from this resistance, maintaining integrity even during prolonged exposure to rain, splashes, or high humidity conditions.

UV and Chemical Resistance

Many PVC inflatable fabrics are formulated with UV stabilizers and chemical-resistant additives. UV protection prevents degradation and brittleness caused by sunlight, while chemical resistance safeguards against chlorine in pools or saltwater in marine environments. These properties enhance both waterproofing and overall durability.

Practical Maintenance Tips to Preserve Waterproofing

Even though PVC inflatable fabric is inherently waterproof, proper maintenance ensures long-term performance. Users should clean the fabric regularly to remove dirt, sand, or chemicals, which can abrade or weaken the surface. Avoid sharp objects and excessive friction to maintain the integrity of the polymer coating and welded seams. Storing inflatables in dry, shaded areas further prolongs waterproof performance.

Maintenance Checklist

- Rinse and clean after exposure to water, especially saltwater

- Inspect seams for signs of wear or leaks

- Avoid overinflation which can stress seams and fabric

- Store in a dry and shaded environment when not in use

- Repair minor punctures promptly with approved patch kits

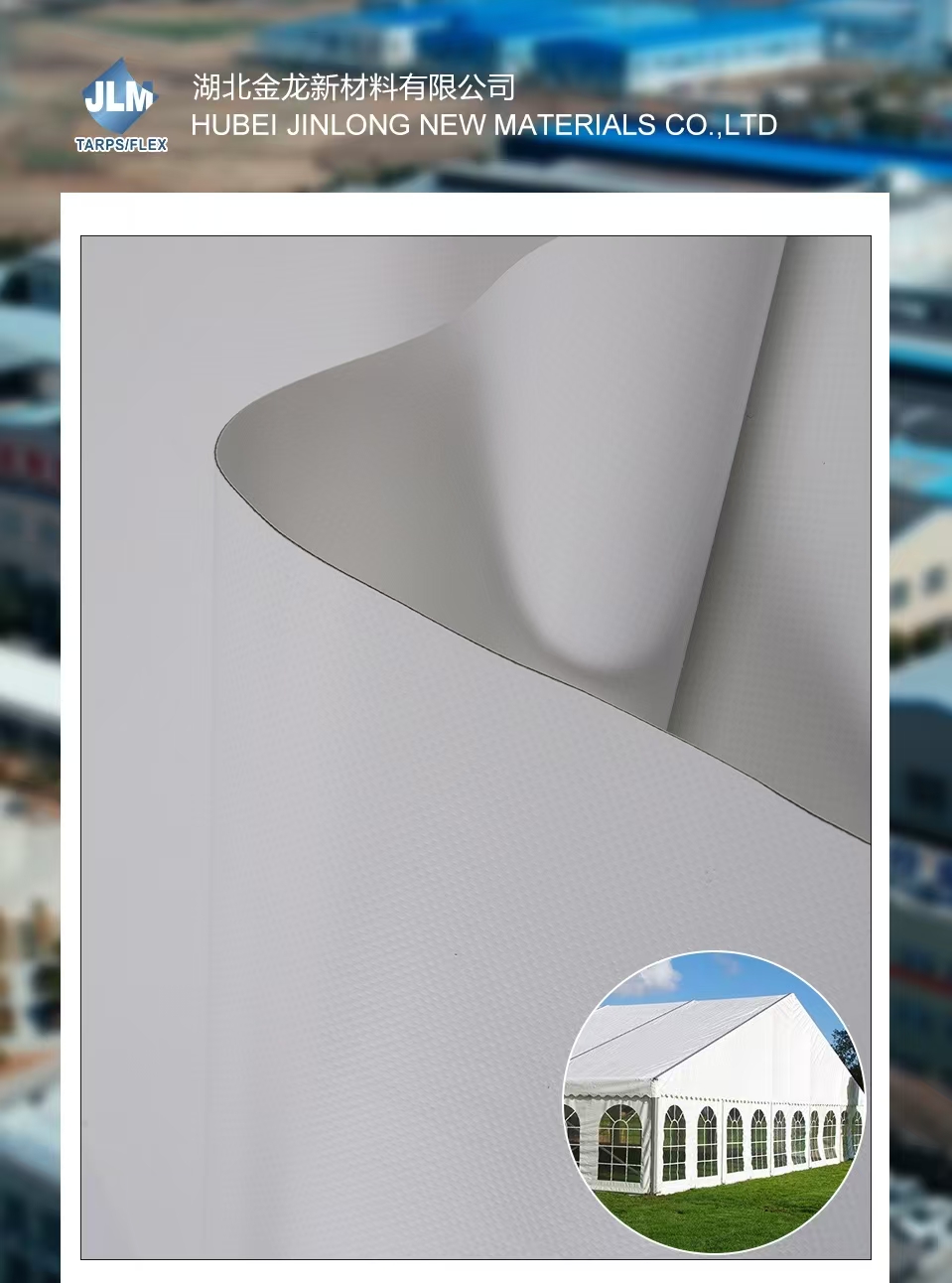

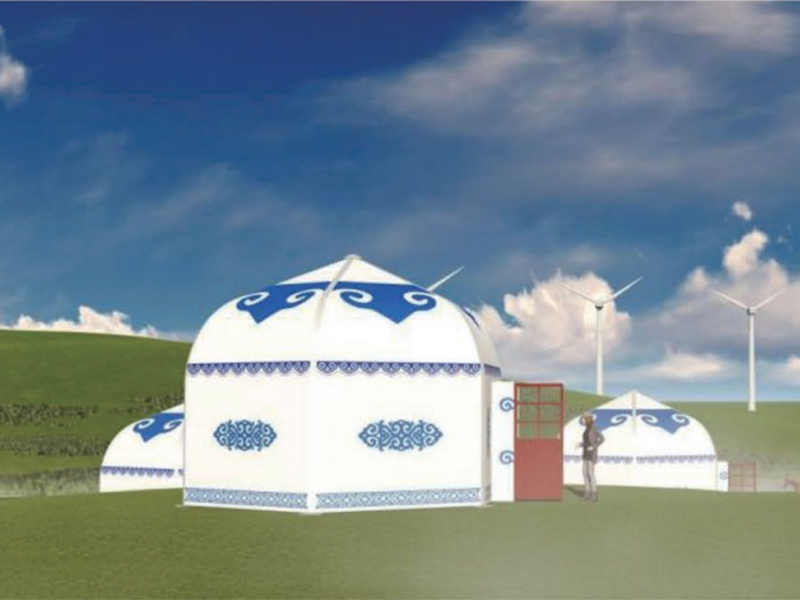

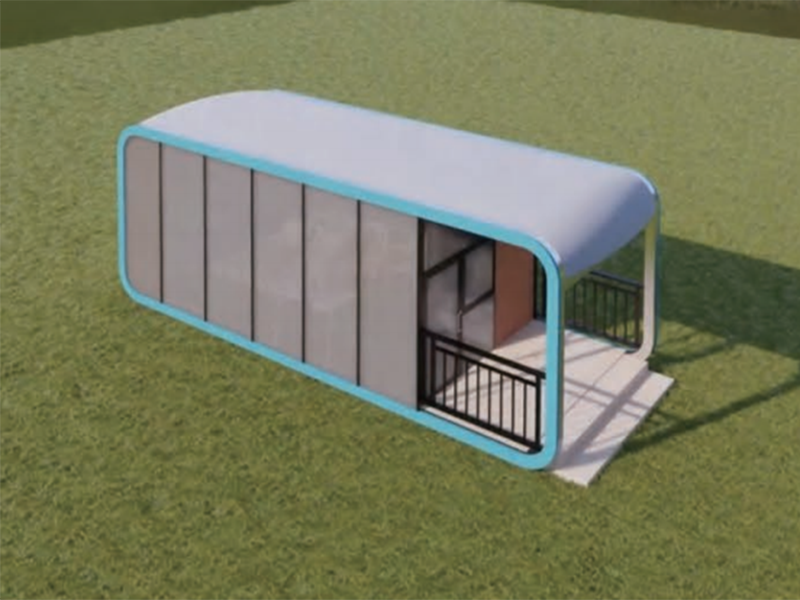

Applications Highlighting Waterproof and Moisture-Proof Performance

The waterproof and moisture-proof properties of PVC inflatable fabric make it suitable for a variety of applications:

- Inflatable boats and kayaks for freshwater and marine use

- Air mattresses and sleeping pads for camping and outdoor recreation

- Inflatable water parks, slides, and swimming pool toys

- Advertising inflatables and promotional structures exposed to weather

- Temporary shelters and tents requiring waterproof protection

Conclusion: Reliability of PVC Inflatable Fabric in Wet Environments

PVC inflatable fabric is highly effective in providing waterproof and moisture-proof performance. Its polymer composition, reinforced structure, and high-quality seam construction ensure durability in water and high-humidity environments. With proper maintenance and care, PVC inflatable fabric maintains its protective qualities, making it a reliable choice for outdoor products, water-based recreational items, and temporary shelters. Understanding its properties and proper usage ensures long-lasting performance and user safety.

English

English русский

русский Français

Français Español

Español