The wear layer in tent construction refers to protective material positioned between the tent floor and the ground to prevent abrasion, punctures, and moisture damage. This critical component, typically made from reinforced polyethylene, heavy-duty nylon, or polyester with waterproof coatings, can extend tent floor lifespan by 300-500% while improving overall shelter performance. Whether integrated into the tent design as a bathtub floor or used as a separate footprint, the wear layer serves as the primary defense against the harsh conditions that cause most tent failures.

Primary Materials Used in Tent Wear Layers

Polyethylene (PE) Ground Sheets

Polyethylene remains the most economical wear layer material, with thicknesses ranging from 0.12mm to 0.25mm for standard applications. Budget camping tents frequently incorporate PE ground sheets weighing 120-180 gsm, offering basic protection against moisture and light abrasion. While PE provides excellent waterproofing with hydrostatic head ratings of 3,000-5,000mm, it demonstrates limited tear resistance and can degrade under prolonged UV exposure, typically lasting 50-100 nights of use before requiring replacement.

Ripstop Nylon with PU Coating

Premium backpacking tents utilize ripstop nylon (typically 30D to 70D) treated with polyurethane coatings reaching 3,000-10,000mm waterproof ratings. The ripstop weave pattern, characterized by reinforcement threads at 5-8mm intervals, prevents small tears from propagating across the fabric. Field testing shows that 70D ripstop nylon with 5,000mm PU coating withstands over 500 hours of abrasion testing, equivalent to approximately 200-250 nights of camping on varied terrain.

Reinforced Polyester Fabric

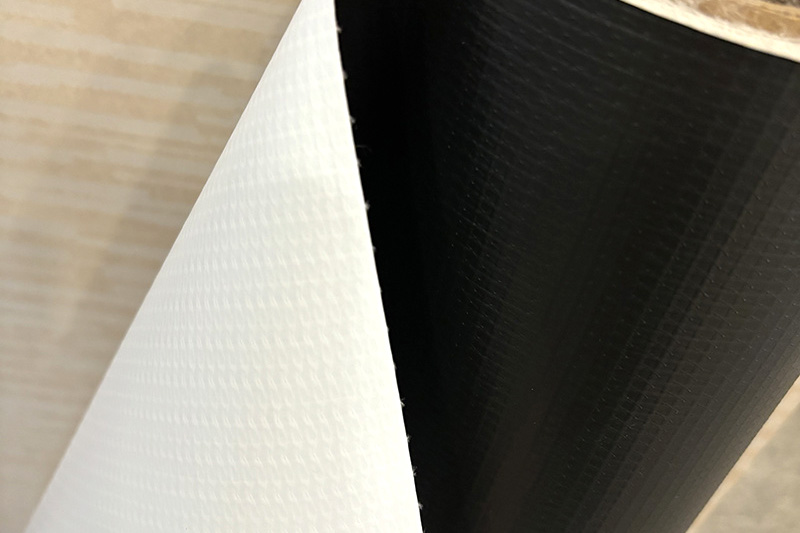

Heavy-duty expedition and family tents employ polyester wear layers in 150D to 420D denier weights, often with dual PU and silicone coatings. This combination delivers exceptional puncture resistance—testing demonstrates that 210D polyester requires 45-60% more force to puncture than comparable nylon. The material maintains flexibility in temperatures from -20°C to +60°C, making it suitable for four-season applications where ground conditions vary dramatically.

Integrated Bathtub Floor Construction

Modern tents incorporate bathtub-style floors where the wear layer material extends 4-8 inches up the tent sidewalls, creating a waterproof basin. This design eliminates horizontal seams at ground level—the most vulnerable point for water infiltration—and provides splash protection during heavy rainfall.

| Floor Type | Waterproof Rating | Puncture Resistance | Typical Weight | Expected Lifespan |

|---|---|---|---|---|

| PE Sheet (Budget) | 3,000-5,000mm | Low | 120-180 gsm | 50-100 nights |

| 70D Nylon + PU | 5,000-8,000mm | Moderate | 85-110 gsm | 200-300 nights |

| 210D Polyester + Coating | 8,000-10,000mm | High | 180-220 gsm | 400-600 nights |

| 420D Oxford Polyester | 10,000mm+ | Very High | 280-350 gsm | 800-1,000 nights |

Professional outfitters report that bathtub floors reduce moisture-related failures by 85-90% compared to flat-seam designs, particularly in wet environments or when camping on snow.

Footprint and Groundsheet Protection Systems

Separate footprints serve as sacrificial wear layers, protecting the tent's integrated floor from direct ground contact. Properly sized footprints should measure 2-3 inches smaller than the tent floor perimeter to prevent water pooling between layers during rainfall.

Material Selection for Footprints

- Reinforced PE tarpaulin (180-250 gsm): Cost-effective solution providing 100-150 nights of protection, ideal for car camping

- Silnylon fabric (40-70D): Lightweight backpacking option weighing 35-55 gsm, offering 200+ nights durability at minimal pack weight

- DCF/Cuben Fiber: Ultra-lightweight option at 15-25 gsm with exceptional tear strength, lasting 300+ nights despite minimal weight

- Heavy-duty vinyl: Professional-grade material (400-600 gsm) for extended expeditions or permanent camps, providing 500+ nights protection

Using a footprint extends tent floor lifespan by an average of 3-4 times, with the footprint absorbing the majority of abrasive damage and allowing for easy replacement at 15-25% of the cost of a new tent.

Coating Technologies for Enhanced Durability

Polyurethane (PU) Coatings

Polyurethane remains the industry standard for tent floor waterproofing, applied in multiple layers to achieve desired hydrostatic head ratings. A single PU coating layer typically provides 1,000-1,500mm waterproofing, with manufacturers applying 3-6 coats to reach 5,000-10,000mm ratings. However, PU coatings degrade through hydrolysis over time, particularly in humid storage conditions, with noticeable deterioration appearing after 3-5 years regardless of use frequency.

Silicone-Based Treatments

Silicone coatings offer superior longevity and UV resistance compared to PU alternatives. While providing lower initial waterproof ratings of 2,000-4,000mm per coating, silicone maintains performance characteristics for 8-12 years without hydrolytic degradation. Premium tents often combine both technologies, applying PU to the interior for waterproofing and silicone to the exterior for abrasion resistance and UV protection.

TPU (Thermoplastic Polyurethane) Films

Advanced expedition tents incorporate TPU laminate films that bond directly to fabric substrates. This technology delivers waterproof ratings exceeding 20,000mm while maintaining breathability levels of 3,000-5,000 g/m²/24hr. TPU films resist hydrolysis better than PU coatings and can withstand over 100,000 flex cycles without cracking, translating to 10+ years of reliable performance in demanding conditions.

Wear Layer Thickness and Performance Trade-offs

Material thickness directly impacts protection level, weight, and packability. Understanding these relationships enables informed decisions based on intended use:

| Application Type | Recommended Denier | Weight (2-person tent) | Protection Level |

|---|---|---|---|

| Ultralight Backpacking | 30D-50D Nylon | 180-280g | Moderate |

| Standard Backpacking | 70D Nylon/Polyester | 320-450g | Good |

| Car Camping/Family | 150D-210D Polyester | 650-900g | Excellent |

| Expedition/Base Camp | 210D-420D Polyester | 1,100-1,600g | Maximum |

Ultralight enthusiasts accept reduced durability to minimize pack weight, while expedition users prioritize maximum protection despite weight penalties. Each 30D increase in fabric weight adds approximately 120-180 grams to a typical two-person tent floor but increases puncture resistance by 25-35%.

Common Wear Layer Failure Modes and Prevention

Abrasion Damage

Continuous friction from occupant movement causes progressive thinning of floor material, particularly in high-traffic areas near the entrance and sleeping positions. Laboratory testing demonstrates that 50D nylon loses 50% of its thickness after 400 hours of standardized abrasion, while 210D polyester maintains 75% thickness under identical conditions. Preventive measures include using sleeping pads that cover the entire floor area and rotating tent orientation to distribute wear patterns.

Puncture and Tear Incidents

Sharp rocks, thorns, and debris cause immediate catastrophic failures in thin wear layers. Field data from backpacking organizations indicates that punctures account for 45-50% of tent floor failures, with incidents occurring most frequently during setup on unprepared ground. Thorough site clearing, removing all sharp objects from a 12-inch radius beyond tent perimeter, reduces puncture risk by approximately 80%.

Coating Delamination

Waterproof coatings separate from base fabrics due to hydrolysis, UV exposure, or improper storage. This manifests as sticky, flaking material that compromises waterproofing. Storage in cool, dry conditions with minimal UV exposure extends coating life by 60-80% compared to storage in hot, humid environments. Annual inspection and reapplication of aftermarket sealants can restore waterproofing to floors showing early delamination signs.

Specialized Wear Layer Materials for Extreme Conditions

Winter and Snow Camping

Cold-weather tents require wear layers that remain flexible at temperatures below -20°C while resisting damage from sharp ice crystals. Manufacturers utilize silicone-impregnated polyester or nylon blends with plasticizers that prevent brittleness in extreme cold. These materials maintain 85-90% of their room-temperature flexibility at -30°C, compared to standard PU-coated fabrics which become rigid and crack-prone below -15°C.

Desert and Rocky Terrain

Harsh desert environments demand maximum puncture resistance combined with UV stability. Heavy-duty floors incorporate 420D Oxford weave polyester with dual UV inhibitors and reinforced corner patches that double material thickness at stress points. These specialized wear layers withstand surface temperatures exceeding 70°C and resist degradation from intense solar radiation—maintaining 90% of original strength after 1,000 hours of UV exposure compared to 60-70% retention in standard materials.

Tropical and High-Humidity Climates

Continuous moisture exposure accelerates PU coating hydrolysis and promotes mold growth on fabric substrates. Tropical-specific wear layers employ antimicrobial treatments and silicone-based waterproofing that resist biological degradation. Field research in Southeast Asian rainforests shows that silicone-treated floors maintain waterproofing for 4-6 years in high-humidity conditions, while standard PU coatings fail within 18-24 months.

Maintenance Practices to Maximize Wear Layer Longevity

Proper care significantly extends the functional life of tent wear layers beyond manufacturer specifications:

- Clean floors with mild soap and water after each trip, removing organic debris that retains moisture

- Dry tents completely before storage, ensuring no moisture remains trapped in seams or coating layers

- Store in loosely rolled or draped configuration to prevent coating stress from tight folds

- Avoid prolonged UV exposure during setup by limiting daytime pitching on sunny days

- Inspect waterproof coating annually, applying seam sealer or refresher treatments when beading diminishes

- Repair small punctures immediately with appropriate patch materials to prevent tear propagation

Campers who follow these protocols report 40-60% longer floor lifespan compared to those who practice minimal maintenance, with properly cared-for tents often exceeding manufacturer durability estimates by 200-300 nights of use.

Cost-Benefit Analysis of Wear Layer Quality

Budget tents with basic PE floors cost $80-150 but typically require replacement every 50-100 nights, resulting in a per-night cost of $0.80-$3.00 when floor failure necessitates full tent replacement. Mid-range tents with 70D nylon floors priced at $250-400 deliver 200-300 nights of use, reducing per-night costs to $0.85-$2.00.

Premium tents featuring 210D polyester floors cost $400-700 but provide 400-600 nights of reliable service, lowering per-night costs to $0.65-$1.75. When factoring in replacement hassle, disposal environmental impact, and performance confidence, high-quality wear layers demonstrate clear economic advantages for regular campers who exceed 20-30 nights annually.

Alternatively, using a $40-80 footprint with a budget tent extends floor life by 3-4 times, achieving comparable cost-effectiveness to mid-range tent investment while maintaining upgrade flexibility.

English

English русский

русский Français

Français Español

Español