Understanding Banner Hem Tape and Material Compatibility

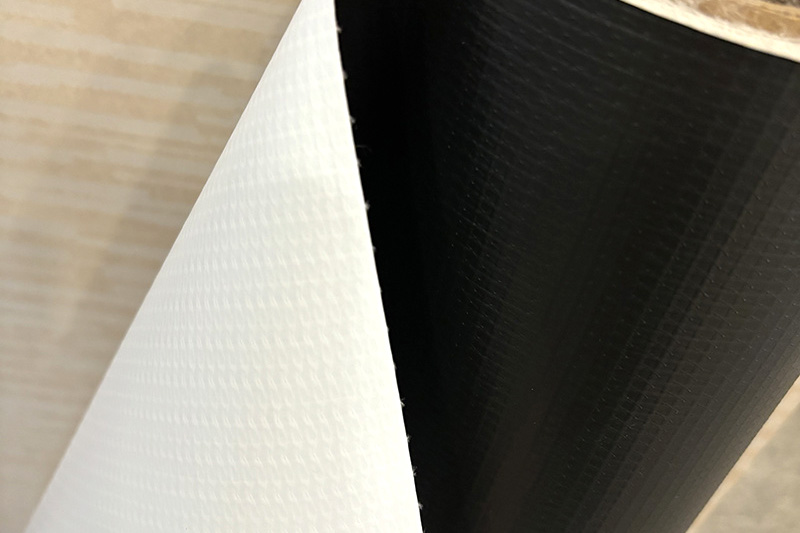

Banner hem tape is a pressure-sensitive or heat-activated adhesive tape designed to reinforce banner edges without sewing. It creates a clean, durable hem that improves strength around grommets and prevents edge fraying. However, not all banner materials bond equally well with banner hem tape. Adhesion performance depends on surface texture, coating type, flexibility, and environmental exposure. Understanding material compatibility is essential to achieving long-lasting results.

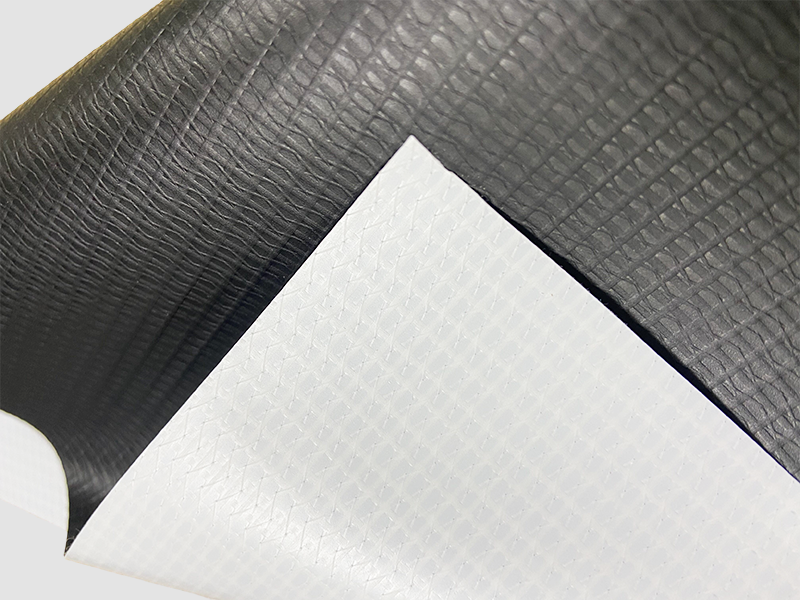

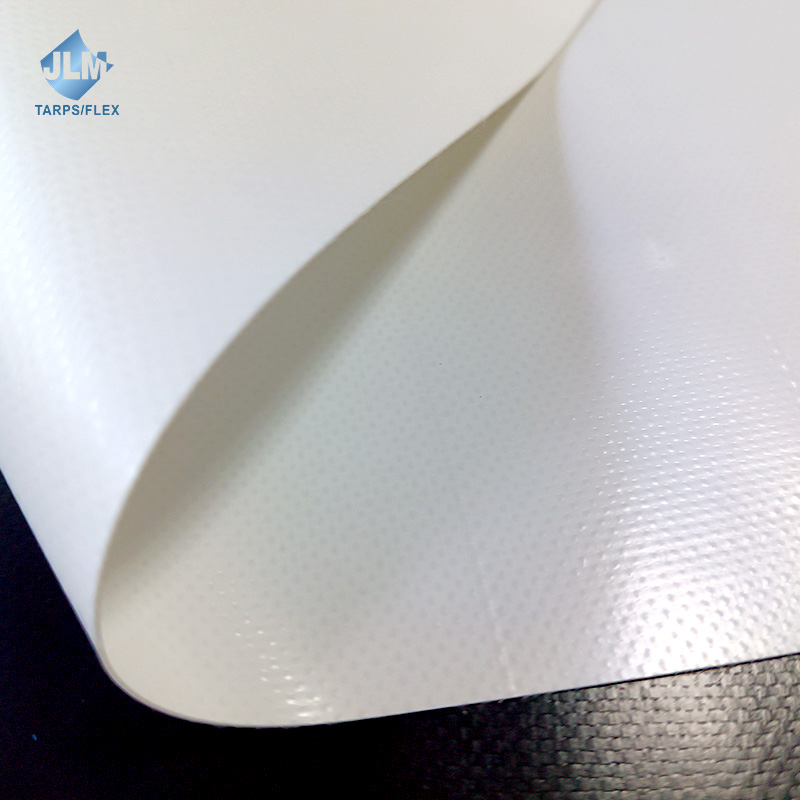

PVC Vinyl Banners

PVC vinyl is the most common and reliable material for use with banner hem tape. Its smooth, coated surface allows strong adhesive bonding, making it ideal for both pressure-sensitive and heat-activated hem tapes.

Frontlit and Backlit Vinyl

Frontlit vinyl banners, typically 13oz or 18oz, work exceptionally well with banner hem tape. Backlit vinyl, used for illuminated displays, also bonds effectively as long as the surface is clean and free of ink overspray near the edges.

Why PVC Vinyl Works Well

- Consistent surface coating ensures uniform adhesion

- Flexible enough to fold clean hems without cracking

- High tensile strength supports grommets and wind load

Mesh Banner Materials

Mesh banners are commonly used outdoors due to their wind-resistant perforated structure. While banner hem tape can be used on mesh materials, special considerations are required to ensure adequate bonding.

Adhesion Challenges with Mesh

The open weave of mesh banners reduces the available surface area for adhesive contact. Standard hem tape may not fully seal the hem unless applied with sufficient pressure or combined with edge reinforcement strips.

Best Practices for Mesh Banners

- Use wider banner hem tape to increase bonding area

- Apply strong pressure during installation

- Avoid mesh with oversized perforations near edges

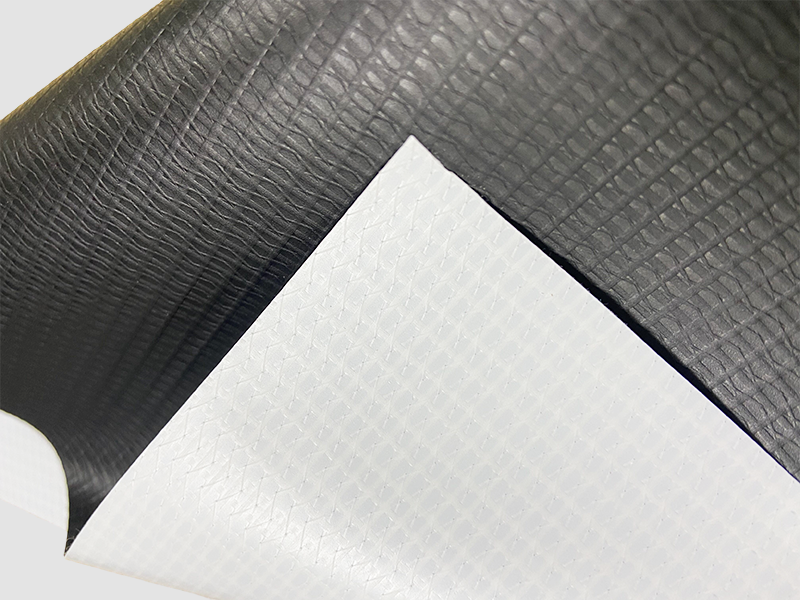

Fabric and Textile Banners

Fabric banners, such as polyester or tension fabric, present more limitations when used with banner hem tape. These materials are porous and flexible, which can reduce adhesive effectiveness.

Polyester Fabric Banners

Polyester banners with coating or laminated backing may accept banner hem tape better than untreated fabrics. However, the bond strength is generally lower compared to vinyl banners.

When to Avoid Hem Tape on Fabric

- Soft knit fabrics with high stretch

- Uncoated textiles with visible fiber texture

- Banners intended for repeated folding and washing

Polypropylene (PP) and PET Banners

Polypropylene and PET-based banner materials are often used for short-term indoor promotions. Their smooth surface can work with banner hem tape, but adhesion varies by coating type.

Surface Treatment Considerations

Some PP and PET banners feature anti-static or ink-receptive coatings that interfere with adhesive bonding. Testing hem tape adhesion before full production is strongly recommended.

Recommended Use Scenarios

- Indoor retail signage

- Short-term event banners

- Wall-mounted displays without heavy tension

Canvas and Heavy Art Media

Canvas banners and heavy art media are generally not ideal for banner hem tape. Their textured surfaces and stiffness limit adhesive penetration and long-term durability.

Why Adhesion Is Limited

Canvas fibers absorb adhesive unevenly, resulting in weak bonding. Over time, hems may peel or distort under tension or humidity changes.

Material Compatibility Comparison

| Banner Material | Hem Tape Compatibility | Recommended Use |

| PVC Vinyl | Excellent | Indoor & Outdoor |

| Mesh Vinyl | Good | Outdoor Windy Areas |

| Polyester Fabric | Limited | Light Indoor Use |

| PP / PET Banner | Moderate | Short-Term Displays |

| Canvas | Poor | Not Recommended |

Environmental and Usage Considerations

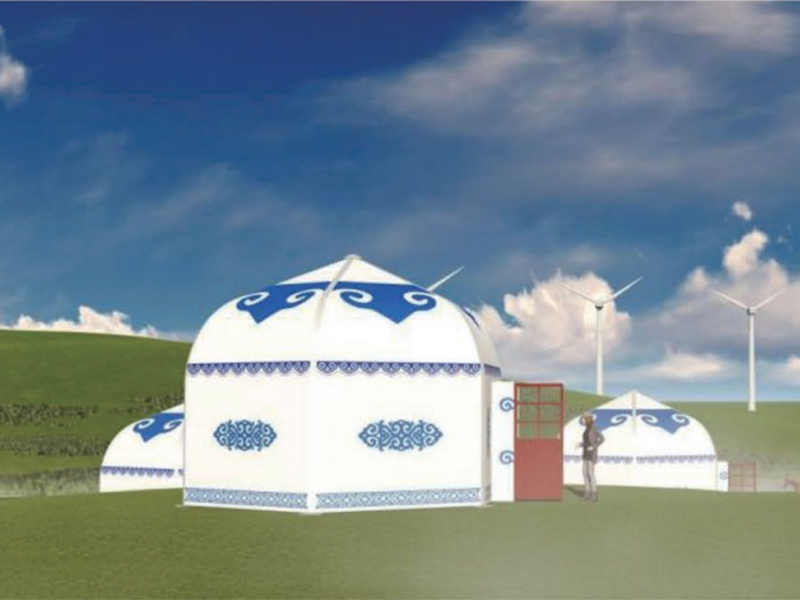

Even when a banner material is compatible with banner hem tape, environmental factors can affect performance. Outdoor exposure introduces UV radiation, moisture, and temperature fluctuations that stress adhesive bonds.

Indoor vs Outdoor Use

Indoor banners experience minimal stress and allow for broader material compatibility. Outdoor banners require vinyl-based materials with strong adhesive bonding to prevent hem failure.

Load and Tension Factors

Banners with frequent wind movement or heavy grommet tension should always use materials with high tear resistance and proven hem tape compatibility, such as reinforced PVC vinyl.

Conclusion

Banner hem tape performs best on smooth, coated banner materials that allow consistent adhesive contact. PVC vinyl remains the most suitable and reliable option, while mesh banners can work with proper technique. Fabric, canvas, and heavily textured materials present challenges and should be evaluated carefully before use. By selecting the right banner material and applying hem tape correctly, you can achieve clean hems, improved durability, and professional results for both indoor and outdoor applications.

English

English русский

русский Français

Français Español

Español