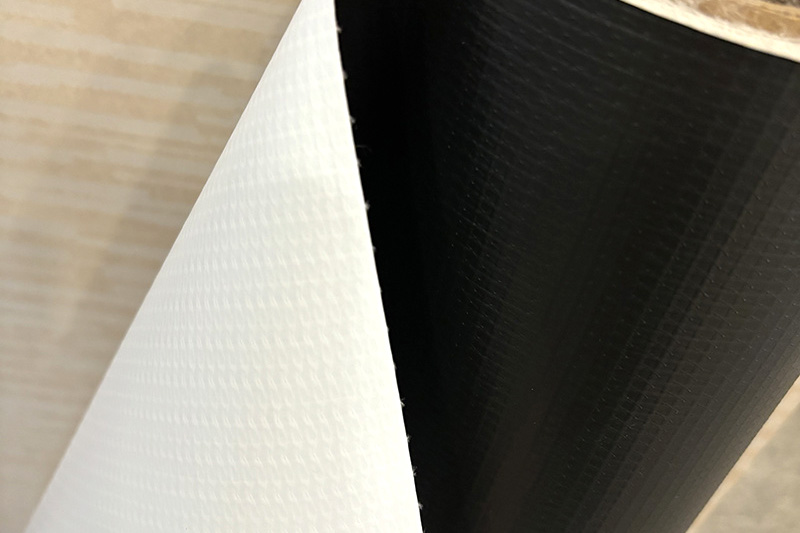

Introduction to TPU Fabric

Thermoplastic polyurethane (TPU) fabric is gaining popularity in both industrial and consumer markets due to its unique combination of elasticity, durability, and waterproof properties. TPU is a versatile polymer that can be applied as a coating or laminated onto textiles, offering enhanced performance characteristics. This article explores the advantages, applications, and practical considerations of TPU fabrics, highlighting why they are becoming a preferred choice in modern material engineering.

Key Advantages of TPU Fabric

TPU fabrics provide a range of benefits that distinguish them from traditional fabrics and coatings. Their performance in extreme conditions makes them ideal for applications where durability and flexibility are essential.

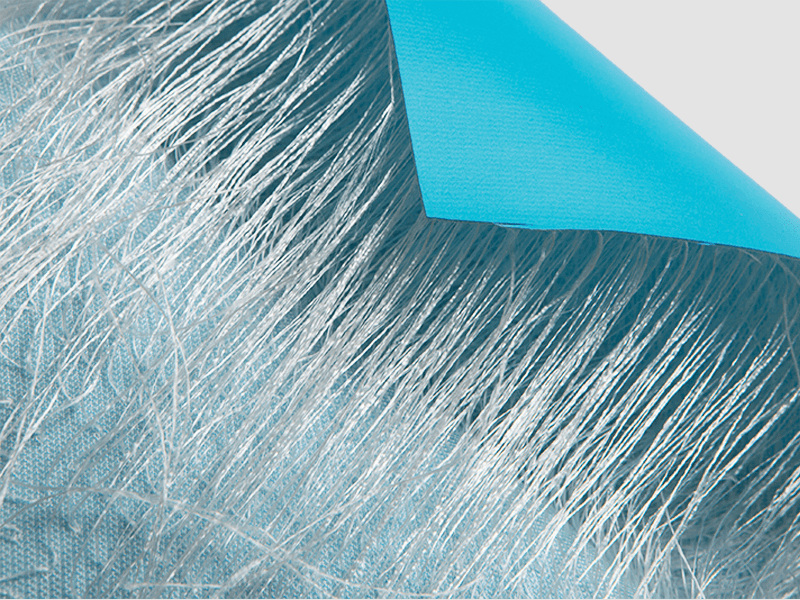

High Durability and Tear Resistance

One of the most notable advantages of TPU fabric is its exceptional durability. TPU-coated fabrics resist tearing, punctures, and abrasion, making them suitable for heavy-duty applications such as industrial protective gear, outdoor tents, and luggage. The elastic nature of TPU allows the fabric to stretch without compromising strength, extending the lifespan of the product.

Flexibility and Comfort

TPU fabrics maintain flexibility even in cold temperatures, unlike some rigid coatings that may crack. This property makes TPU suitable for wearable items such as sportswear, gloves, and shoes, where comfort and freedom of movement are essential. The soft, smooth surface of TPU-coated textiles also improves tactile comfort for end-users.

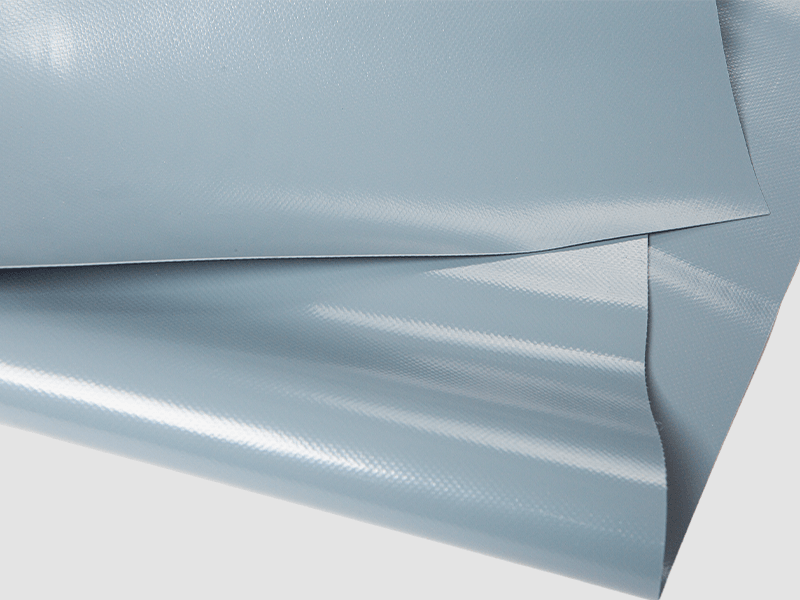

Waterproof and Weather Resistance

TPU coatings provide excellent waterproofing without affecting breathability, making the fabric ideal for outdoor gear and protective clothing. The material resists moisture, UV rays, and mildew, which extends product life in harsh environmental conditions. This combination of waterproofing and flexibility differentiates TPU from conventional PVC coatings that may become brittle over time.

Applications of TPU Fabric

TPU fabrics are highly versatile and are used across multiple industries. Their properties make them suitable for both high-performance industrial applications and consumer products.

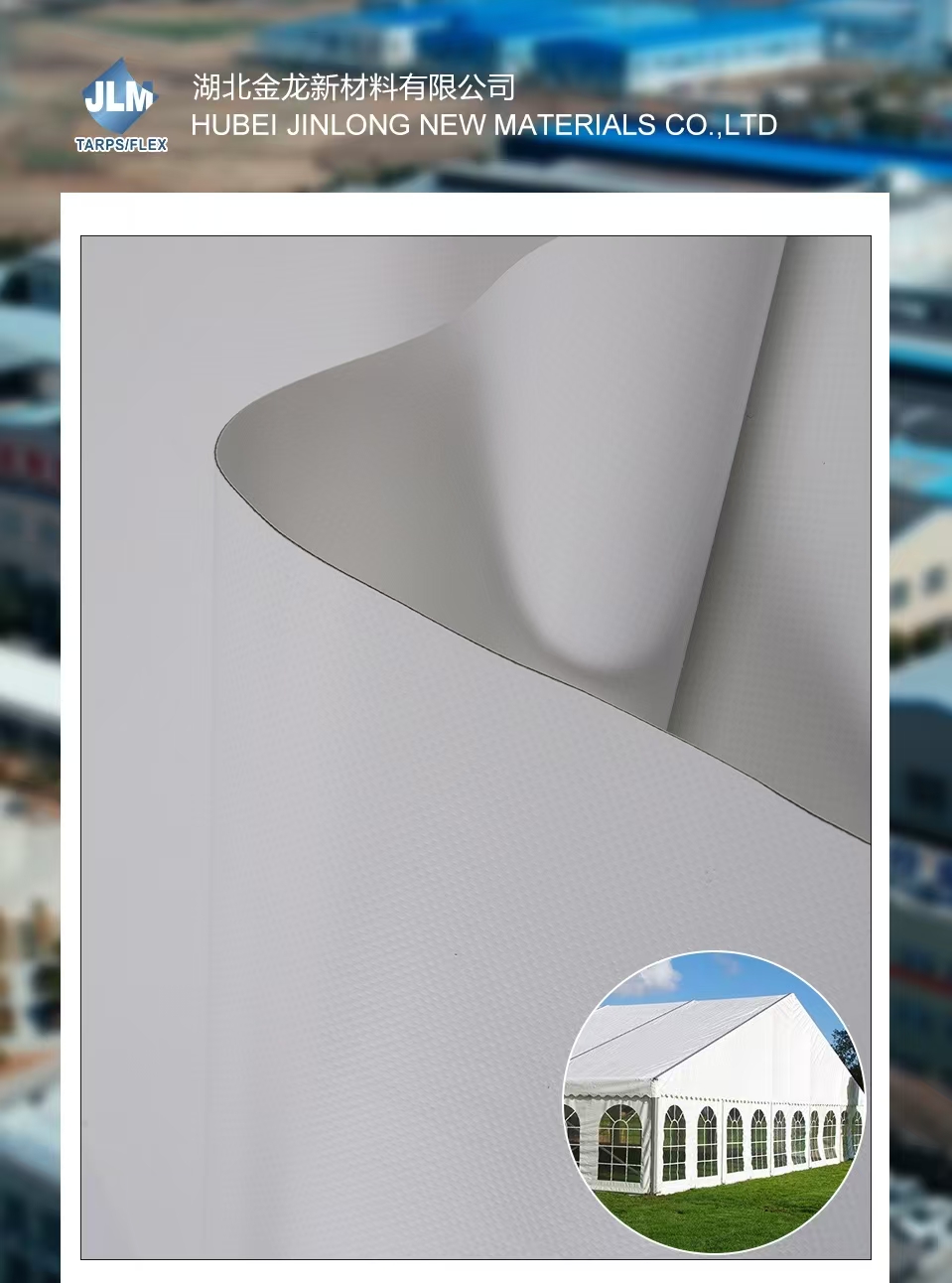

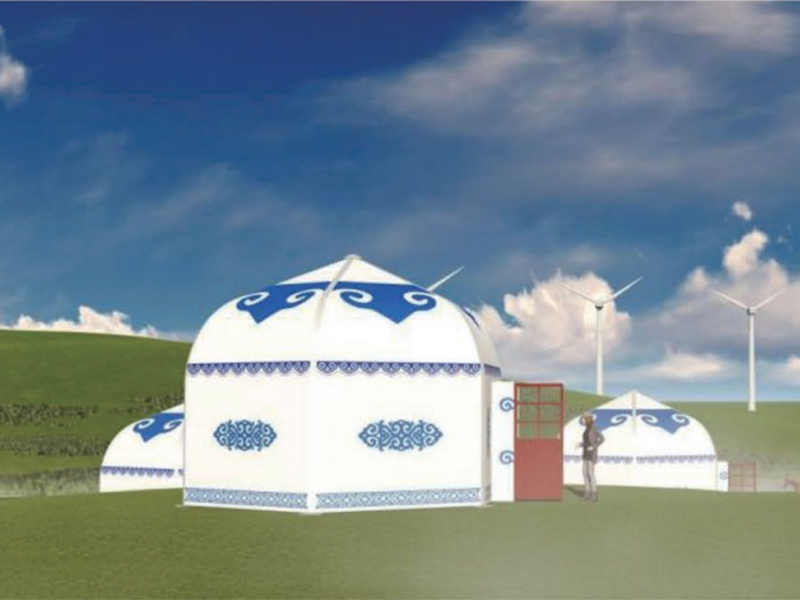

Outdoor Gear and Protective Clothing

Due to its waterproof and tear-resistant properties, TPU fabric is widely used in tents, rain jackets, sleeping bags, and hiking gear. It ensures protection from weather elements while maintaining flexibility and comfort for the user.

Medical and Healthcare Applications

TPU fabrics are utilized in medical equipment such as braces, protective covers, and surgical garments due to their biocompatibility and resistance to bacteria. The material can be sterilized without losing its elasticity or structural integrity, making it ideal for reusable medical products.

Industrial and Technical Uses

In industrial applications, TPU-coated fabrics are used for conveyor belts, protective curtains, and inflatable structures. Their strength, flexibility, and resistance to chemicals and abrasion make them ideal for demanding environments. TPU fabrics can also be engineered to specific thicknesses and hardness levels for precise performance requirements.

Consumer Goods and Footwear

TPU is widely used in the fashion and footwear industries for items such as bags, jackets, and sneakers. It allows designers to create waterproof, durable, and visually appealing products. Transparent TPU coatings also provide design versatility, enabling colorful or glossy finishes without compromising fabric strength.

Comparison of TPU with Other Coating Materials

To understand the advantages of TPU fabrics, it is helpful to compare them with other commonly used coating materials such as PVC, silicone, and PU.

| Feature | TPU | PVC | Silicone |

| Flexibility | High | Moderate | High |

| Durability | High | Moderate | High |

| Waterproof | Excellent | Good | Excellent |

| Eco-Friendliness | High | Low | High |

Maintenance and Care of TPU Fabrics

Proper maintenance extends the lifespan of TPU fabrics. These fabrics are easy to clean, resistant to stains, and do not require special chemicals. For long-term use, it is recommended to avoid prolonged exposure to extreme UV radiation, which may affect elasticity over time.

Cleaning Guidelines

TPU-coated fabrics can be cleaned with mild soap and water. Abrasive cleaners should be avoided to prevent surface damage. For industrial or medical applications, TPU fabrics can withstand sterilization methods such as autoclaving or chemical disinfectants without compromising structural integrity.

Storage Recommendations

To preserve TPU fabrics, store them in a cool, dry environment. Avoid folding or compressing heavily, as prolonged pressure may create permanent creases. Proper storage ensures the material retains flexibility and waterproof properties.

Future Trends and Innovations

Advances in TPU formulations and coating technologies continue to expand the potential applications of TPU fabrics. New innovations include biodegradable TPU variants, enhanced UV resistance, and improved bonding techniques for composite materials. These developments are expected to increase TPU adoption across diverse sectors, from wearable electronics to eco-friendly consumer goods.

Conclusion

TPU fabrics offer a unique combination of durability, flexibility, waterproofing, and eco-friendliness, making them a highly versatile material for both industrial and consumer applications. From outdoor gear and medical equipment to fashion and footwear, TPU fabrics provide practical and sustainable solutions. By understanding their advantages, applications, and proper care, manufacturers and consumers can fully leverage the benefits of TPU fabrics for long-lasting and high-performance products.

English

English русский

русский Français

Français Español

Español