Introduction to PVC Inflatable Fabrics

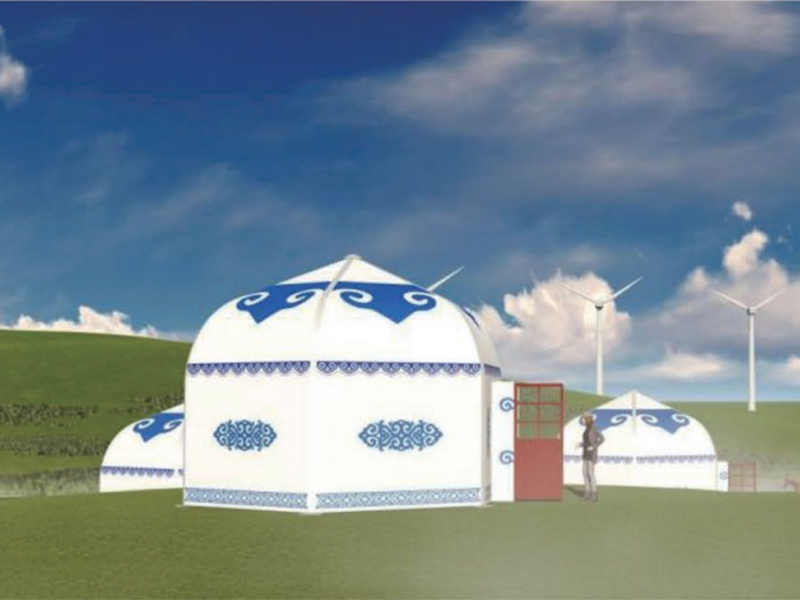

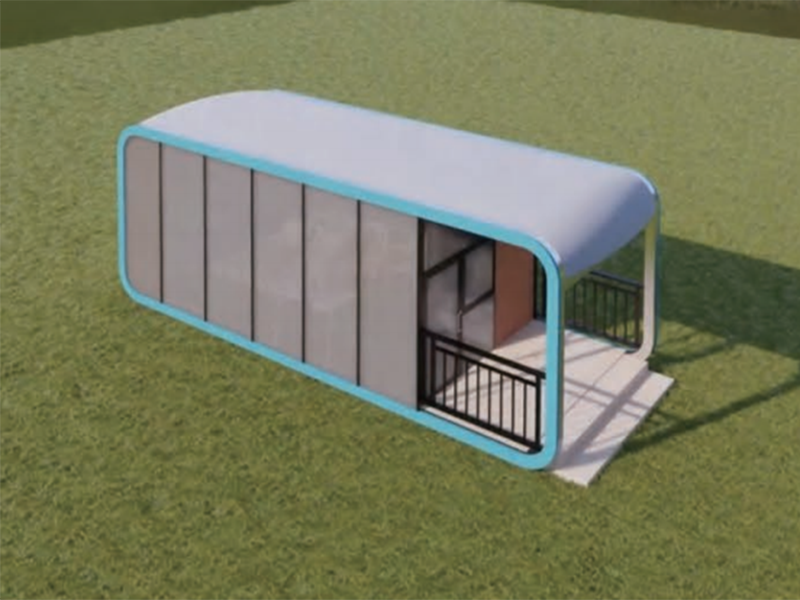

PVC inflatable fabrics are widely used in air-supported structures, inflatable furniture, water sports equipment, and temporary shelters. Their durability, flexibility, and cost-effectiveness make them highly popular. However, questions about sustainability and environmental impact are increasingly relevant as industries and consumers demand eco-friendly solutions.

This article explores whether PVC inflatable fabrics are sustainable and environmentally friendly, examining material composition, production processes, recyclability, and potential improvements for greener solutions.

Material Composition and Environmental Concerns

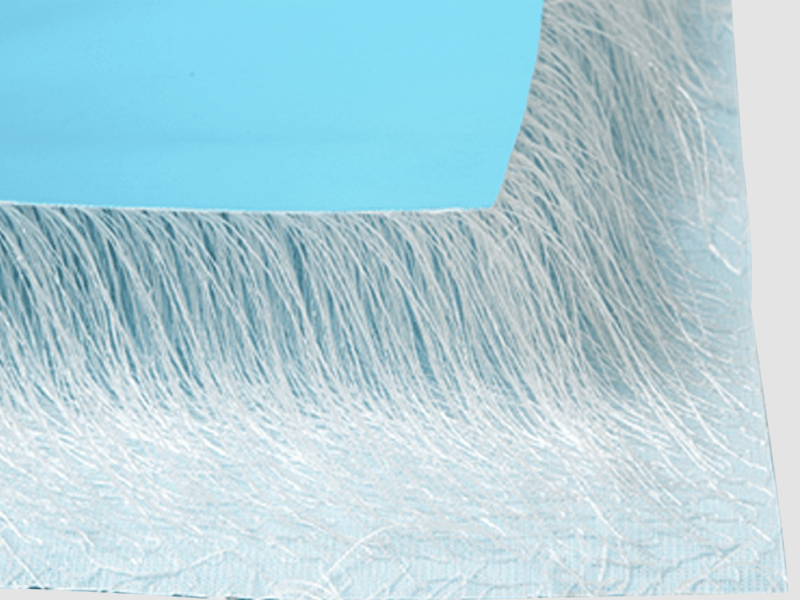

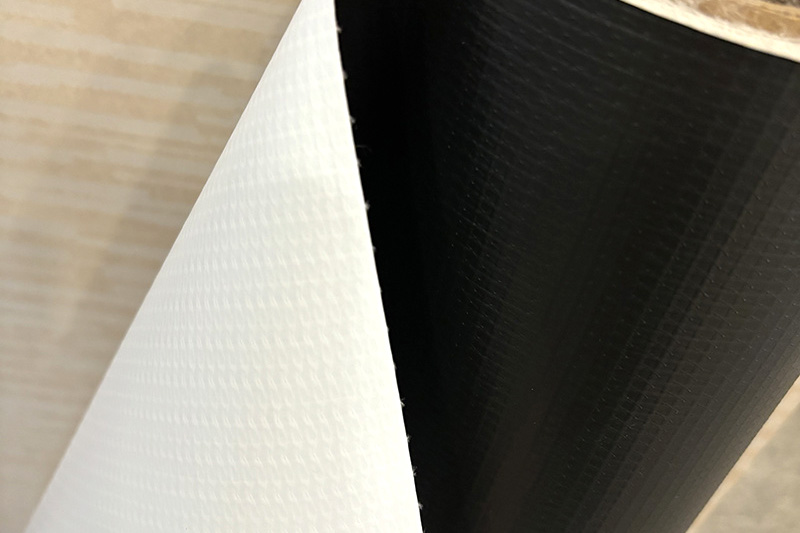

PVC, or polyvinyl chloride, is a widely used thermoplastic polymer. PVC inflatable fabrics are typically composed of PVC-coated polyester or nylon fabrics, combining flexibility with strength. While PVC provides excellent durability and water resistance, its production involves chlorine and additives that can impact the environment.

Additives such as plasticizers, stabilizers, and flame retardants may contribute to toxicity during manufacturing and disposal. Understanding the environmental footprint of PVC materials is critical in assessing their sustainability.

Production Process and Carbon Footprint

PVC production involves polymerization of vinyl chloride monomer (VCM), a process that consumes energy and generates emissions. The coating and lamination processes used to create inflatable fabrics further increase energy use. Manufacturers are increasingly adopting cleaner production methods, such as energy-efficient extrusion, low-VOC additives, and emission controls, to reduce environmental impact.

Durability and Lifecycle Assessment

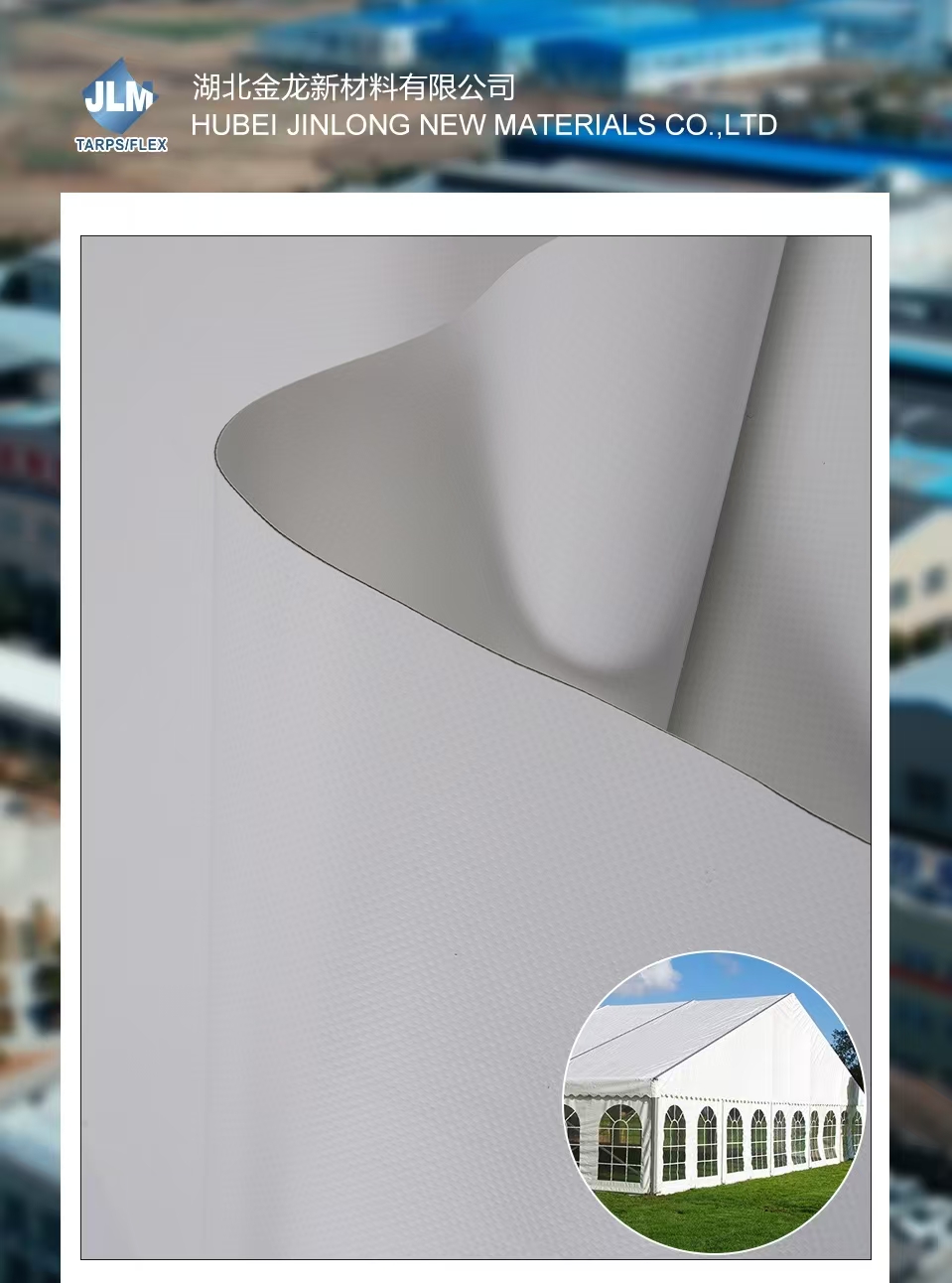

One factor supporting sustainability is the long lifespan of PVC inflatable fabrics. High-quality fabrics can last for several years under frequent use, reducing the need for frequent replacement. Durable materials also lower overall environmental impact by minimizing waste compared to less durable alternatives.

Lifecycle assessments consider production, use, maintenance, and end-of-life disposal. PVC inflatable fabrics perform well during the use phase due to low maintenance requirements, resistance to UV, water, and abrasion, making them efficient and cost-effective over time.

Recycling and End-of-Life Management

Recycling PVC inflatable fabrics is challenging but not impossible. Mechanical recycling involves shredding and remelting, while chemical recycling can depolymerize PVC back into monomers. However, the presence of coatings, additives, and laminates complicates recycling processes.

Some manufacturers are implementing take-back programs, repurposing used inflatable products into industrial mats, flooring, or insulation materials. Proper end-of-life management significantly improves the sustainability profile of PVC fabrics.

Comparative Sustainability Analysis

Comparing PVC inflatable fabrics with other materials such as TPU (thermoplastic polyurethane) or biodegradable polymers highlights environmental trade-offs. While TPU offers easier recycling and lower chemical concerns, PVC remains cost-effective and highly durable, resulting in fewer replacements and long-term resource savings.

| Material | Durability | Recyclability | Environmental Impact |

| PVC | High | Moderate | Medium |

| TPU | High | High | Lower |

| Biodegradable Polymers | Medium | High | Low |

Eco-Friendly Innovations in PVC Fabrics

The PVC industry has introduced several innovations to improve sustainability. Bio-based plasticizers reduce dependency on petroleum-derived chemicals, and non-toxic stabilizers minimize harmful emissions. Advanced coatings enhance UV resistance and extend product lifespan, indirectly reducing environmental impact.

Additionally, some manufacturers are exploring hybrid materials, combining PVC with TPU or recycled fibers to create more eco-friendly, high-performance inflatable fabrics suitable for both commercial and recreational use.

Maintenance and Longevity Practices

Proper maintenance enhances sustainability by extending product lifespan. Regular cleaning, avoiding prolonged UV exposure, and proper storage reduce wear and degradation. Long-lasting PVC inflatable fabrics require fewer replacements, lowering material consumption and associated environmental impacts.

Conclusion: Evaluating Sustainability of PVC Inflatable Fabrics

PVC inflatable fabrics offer durability and long service life, which supports sustainability through reduced material turnover. However, challenges remain in production emissions, chemical additives, and recycling complexity. With technological innovations, eco-friendly additives, and effective end-of-life management, PVC inflatable fabrics can achieve a more sustainable and environmentally friendly profile.

Manufacturers, consumers, and policymakers must work together to optimize production methods, encourage recycling programs, and explore hybrid materials to ensure PVC inflatable fabrics contribute positively to environmental goals while retaining their functional benefits.

English

English русский

русский Français

Français Español

Español