Understanding the Basics of Drop Stitch Fabric

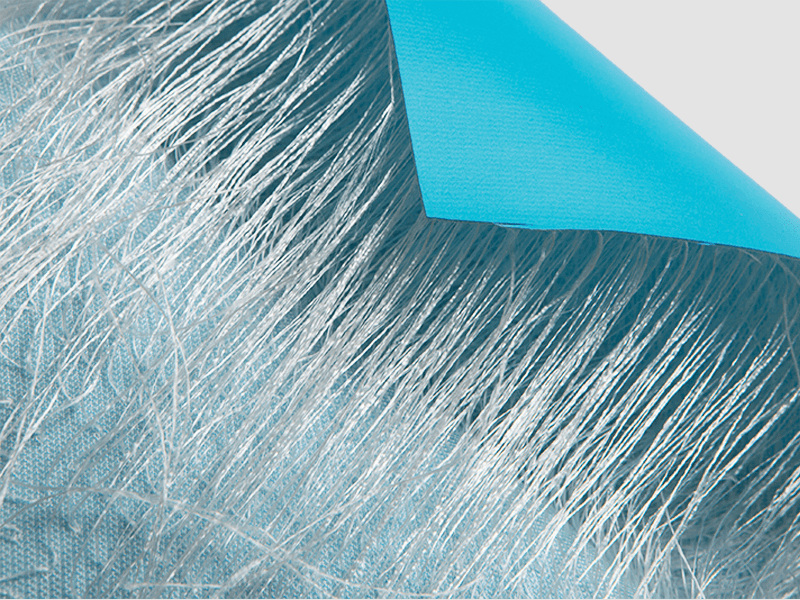

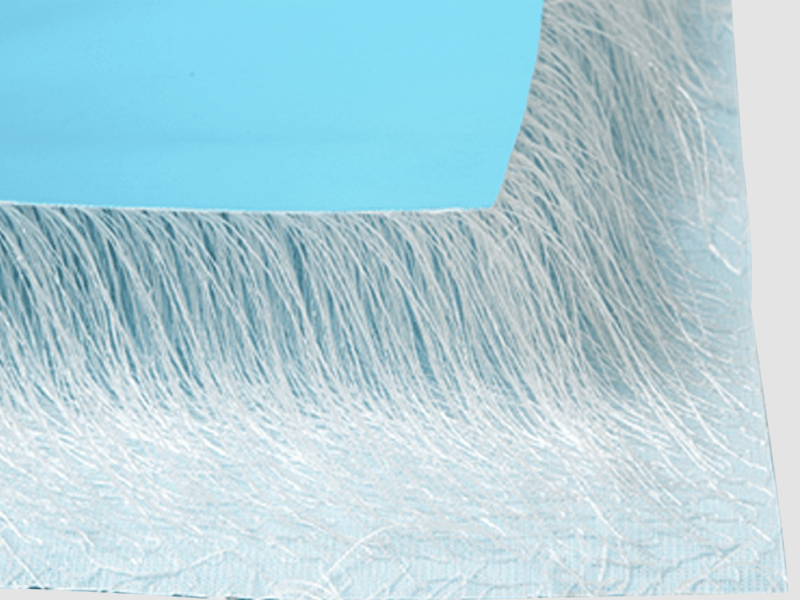

Drop stitch fabric is a specialized textile structure engineered to provide exceptional strength and stability in inflatable products. Unlike conventional inflatable materials that rely on simple air chambers, drop stitch fabric uses thousands of polyester threads to connect two parallel fabric layers. These threads maintain a fixed distance between the surfaces when inflated, allowing the structure to remain flat, rigid, and highly stable.

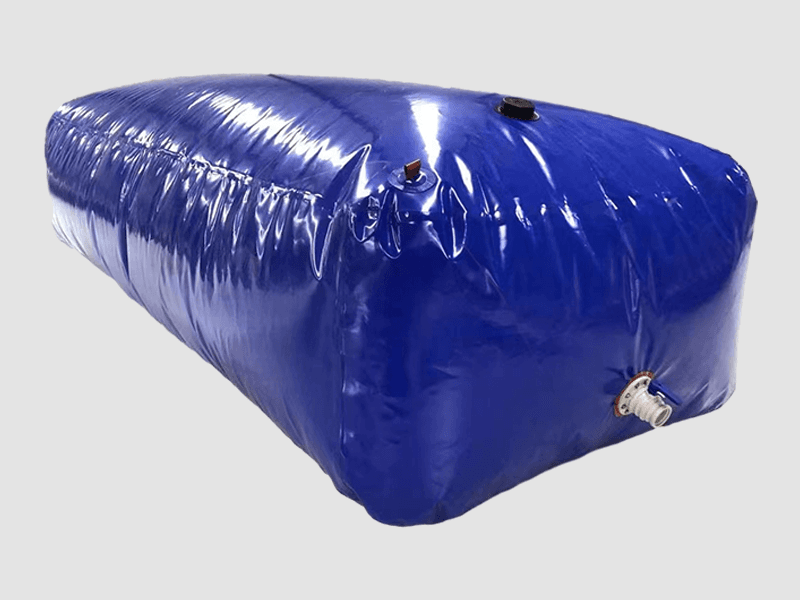

This unique construction has transformed how inflatable products are designed and used. Items such as inflatable paddle boards, boats, docks, gym mats, and rescue equipment can now achieve stiffness levels previously associated only with solid materials. The ability of drop stitch fabric to combine light weight with structural rigidity is the foundation of its growing adoption.

The Internal Thread Structure That Creates Strength

At the core of drop stitch fabric is its dense internal thread system. Thousands of vertical threads connect the top and bottom layers of the fabric, forming a three-dimensional internal framework. When the fabric is inflated, these threads prevent the layers from bulging outward, distributing internal air pressure evenly across the surface.

This distribution of force is what gives drop stitch fabric its remarkable load-bearing capacity. Instead of concentrating stress at specific points, the internal threads work collectively to maintain shape and resist deformation. As a result, the inflatable structure behaves more like a solid panel than a flexible air bladder.

High Thread Density and Its Impact

Thread density plays a critical role in determining strength. Higher-density drop stitch fabric contains more connecting threads per square meter, which increases stiffness and improves resistance to bending. Manufacturers often select different thread densities depending on whether the product prioritizes rigidity, weight reduction, or cost efficiency.

Ability to Withstand High Internal Pressure

One of the defining advantages of drop stitch fabric is its ability to handle significantly higher internal air pressure than traditional inflatable materials. Standard inflatables typically operate at low pressure, resulting in soft and unstable structures. In contrast, drop stitch fabric can safely support high-pressure inflation, dramatically increasing rigidity.

This high-pressure capability allows inflatable products to support heavier loads without sagging. Whether used for standing, walking, or supporting equipment, drop stitch structures maintain their shape and stability even under demanding conditions.

Enhanced Stability Through Even Load Distribution

Stability is not only about strength but also about how forces are distributed. Drop stitch fabric excels in this area by spreading weight evenly across the entire surface. When pressure is applied, such as a person standing on an inflatable board, the internal threads prevent localized deformation.

This even load distribution improves balance and control, which is especially important in applications like water sports or floating platforms. Users experience a stable, predictable surface that enhances safety and performance.

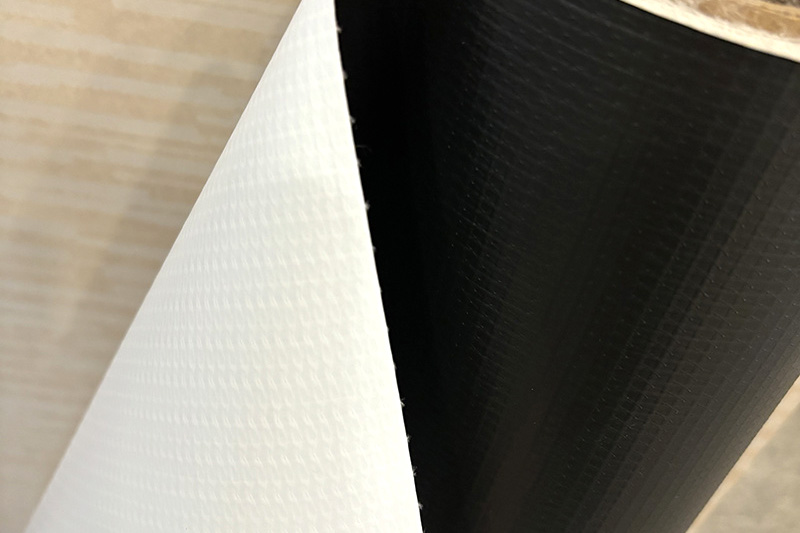

Material Layers That Reinforce Structural Integrity

Drop stitch fabric typically incorporates multiple layers of reinforced PVC or similar coatings on its outer surfaces. These layers protect the internal thread structure while adding tensile strength and abrasion resistance. The bonding process between layers is carefully controlled to prevent air leakage and material separation.

Advanced lamination or fusion techniques further enhance durability. By reducing the need for excessive adhesives, these methods improve consistency and long-term performance, ensuring the fabric maintains its strength after repeated inflation cycles.

Resistance to Deformation and Fatigue

Repeated use can weaken many inflatable materials, but drop stitch fabric is designed to resist fatigue. The internal threads limit stretching, while the outer layers absorb external impacts. This combination allows the fabric to maintain its shape and rigidity over extended periods of use.

Comparison with Traditional Inflatable Fabrics

To fully appreciate how drop stitch fabric improves strength and stability, it is useful to compare it with conventional inflatable materials.

| Feature | Traditional Inflatable Fabric | Drop Stitch Fabric |

| Internal Structure | Single air chamber | Thousands of vertical threads |

| Operating Pressure | Low | High |

| Stability | Soft and flexible | Rigid and stable |

Applications That Rely on Strength and Stability

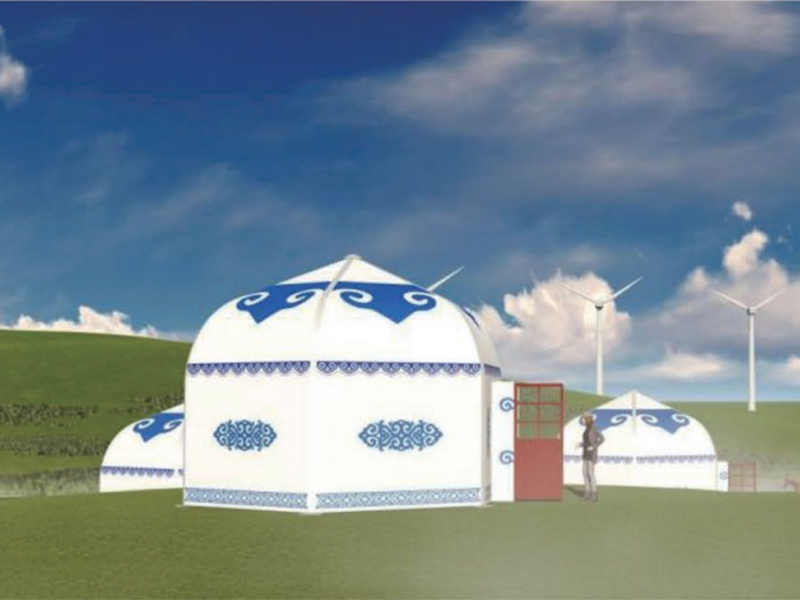

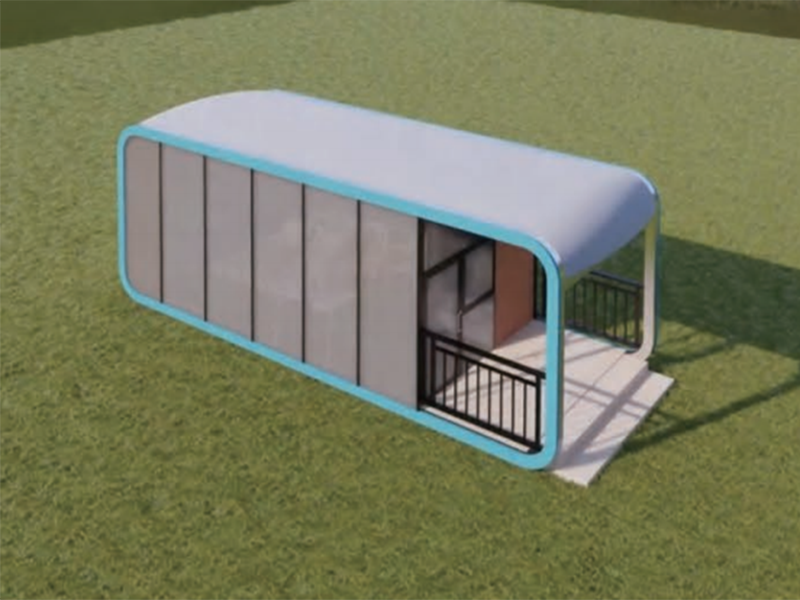

The improved strength and stability of drop stitch fabric have expanded the range of inflatable applications. In water sports, it enables paddle boards and kayaks that feel solid underfoot. In commercial and industrial settings, it supports floating docks, work platforms, and rescue equipment.

Fitness and recreational products also benefit from this material. Inflatable gym mats and training platforms rely on drop stitch fabric to provide a firm, shock-absorbing surface that enhances safety and performance.

Design Flexibility Without Sacrificing Performance

Despite its rigidity when inflated, drop stitch fabric remains flexible when deflated. This allows products to be easily transported and stored, combining the convenience of inflatables with the performance of solid structures. Designers can adjust thickness, shape, and reinforcement patterns to meet specific performance requirements.

This balance between portability and strength is a major reason drop stitch fabric continues to gain popularity across industries.

Long-Term Performance and Reliability

Strength and stability must be sustained over time to deliver real value. Drop stitch fabric is engineered for long-term reliability, with materials selected to resist UV exposure, moisture, and temperature fluctuations. Properly manufactured products retain their structural integrity even after repeated use in demanding environments.

This durability reduces maintenance needs and extends product lifespan, making drop stitch fabric a cost-effective choice for both consumers and commercial operators.

Why Drop Stitch Fabric Continues to Set New Standards

Drop stitch fabric improves strength and stability through its internal thread architecture, high-pressure tolerance, and reinforced material layers. These characteristics allow inflatable products to perform at levels once reserved for rigid constructions.

As innovation continues and manufacturing techniques advance, drop stitch fabric is expected to further redefine what inflatable structures can achieve, offering stronger, more stable, and more reliable solutions across a wide range of applications.

English

English русский

русский Français

Français Español

Español